Zinc bars offer a solid, dense form of zinc ideal for bulk storage and long-term use, while zinc wires provide flexible, easily shaped material suited for precise applications like galvanizing and electronics. The surface area of zinc wire allows for faster reaction rates compared to the solid bar, making it more efficient in certain chemical processes. Choosing between zinc bar and wire depends on the specific needs for durability, reactivity, and ease of handling in pet care or industrial settings.

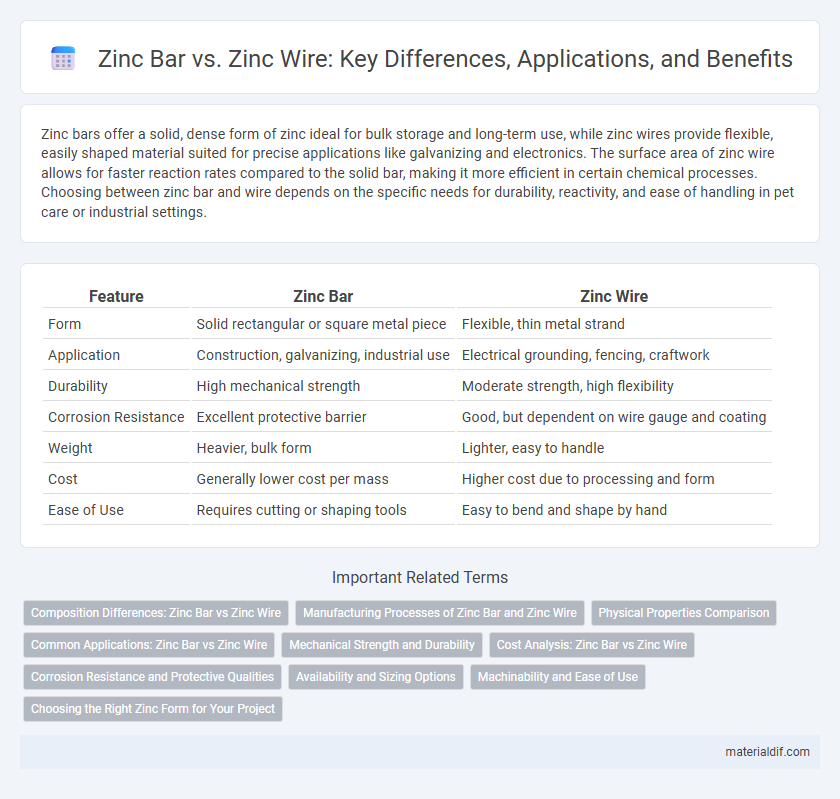

Table of Comparison

| Feature | Zinc Bar | Zinc Wire |

|---|---|---|

| Form | Solid rectangular or square metal piece | Flexible, thin metal strand |

| Application | Construction, galvanizing, industrial use | Electrical grounding, fencing, craftwork |

| Durability | High mechanical strength | Moderate strength, high flexibility |

| Corrosion Resistance | Excellent protective barrier | Good, but dependent on wire gauge and coating |

| Weight | Heavier, bulk form | Lighter, easy to handle |

| Cost | Generally lower cost per mass | Higher cost due to processing and form |

| Ease of Use | Requires cutting or shaping tools | Easy to bend and shape by hand |

Composition Differences: Zinc Bar vs Zinc Wire

Zinc bars are typically composed of high-purity zinc with minimal alloying elements, ensuring uniform density and mechanical strength ideal for industrial applications. Zinc wire often contains alloy additives such as copper or aluminum to enhance flexibility, tensile strength, and corrosion resistance, making it suitable for electrical and crafting purposes. The compositional differences directly affect the physical properties and suitability of zinc bars and wires for specific manufacturing and construction uses.

Manufacturing Processes of Zinc Bar and Zinc Wire

Zinc bars are produced through continuous casting or gravity casting, involving melting zinc ingots and solidifying them into rectangular shapes for ease of storage and transportation. Zinc wire manufacturing requires a more complex process including casting zinc rods followed by hot rolling and drawing through dies to achieve precise diameters and flexibility. The bar production emphasizes high-volume solid forms, while wire manufacturing prioritizes mechanical strength and ductility for industrial applications.

Physical Properties Comparison

Zinc bars exhibit higher tensile strength and lower malleability compared to zinc wires, making bars ideal for structural applications requiring rigidity. Zinc wires offer greater flexibility and conductivity, suitable for electrical uses where bending and shaping are necessary. The density of zinc remains constant in both forms, but the surface area to volume ratio differs, influencing corrosion resistance and heat dissipation characteristics.

Common Applications: Zinc Bar vs Zinc Wire

Zinc bar is commonly utilized in galvanizing steel components for corrosion protection in construction and automotive industries, providing robust and long-lasting protection. Zinc wire finds extensive applications in electrical grounding systems and as raw material in manufacturing brass alloys, offering flexibility and ease of shaping. Both zinc forms are essential in industrial processes, with zinc bars preferred for structural durability and zinc wire favored for precision and conductivity tasks.

Mechanical Strength and Durability

Zinc bars exhibit higher mechanical strength compared to zinc wires, making them ideal for structural applications requiring robust support. Zinc wires, while more flexible and easier to manipulate, generally have lower tensile strength and are more susceptible to deformation under stress. In terms of durability, zinc bars provide better resistance to wear and corrosion due to their solid, compact form, whereas zinc wires may degrade faster when exposed to harsh environmental conditions.

Cost Analysis: Zinc Bar vs Zinc Wire

Zinc bars typically offer lower initial costs due to simpler manufacturing processes and bulk availability, making them more cost-effective for large-scale industrial applications. Zinc wire, while generally more expensive per unit length, provides advantages in flexibility and precision, which can reduce labor costs in specialized projects. Evaluating total expenses involves considering both material price and application-specific factors such as handling efficiency and waste reduction.

Corrosion Resistance and Protective Qualities

Zinc bars exhibit superior corrosion resistance compared to zinc wire due to their solid, uniform structure that provides a consistent protective barrier against environmental elements. Zinc wire, with its thinner and often braided form, may have increased surface area susceptible to faster oxidation and wear, reducing its protective qualities over time. For applications requiring long-term durability and corrosion protection, zinc bars are generally the preferred choice due to their enhanced resistance and more robust protective properties.

Availability and Sizing Options

Zinc bars are readily available in standardized sizes, making them ideal for structural applications that require consistent dimensions and easier handling. Zinc wire offers a broader range of thicknesses and diameters, providing greater flexibility for intricate tasks such as galvanization, crafting, and electrical applications. Availability of zinc wire varies based on gauge and length, while zinc bars typically come in pre-cut lengths and widths suited for manufacturing and industrial use.

Machinability and Ease of Use

Zinc bars offer superior machinability due to their solid, uniform composition, enabling precise cutting and shaping without deformation. Zinc wire, while more flexible and easier to form into intricate shapes, may present challenges in maintaining dimensional accuracy during machining. Selecting zinc bars enhances ease of use in applications requiring tight tolerances and consistent material performance.

Choosing the Right Zinc Form for Your Project

Zinc bars provide a solid, dense form ideal for casting and alloy production, offering high purity and ease of handling. Zinc wire, with its flexible and elongated shape, suits applications requiring precision and intricate detailing, such as galvanizing or battery manufacturing. Selecting the right zinc form depends on project requirements like melting ease, surface area exposure, and mechanical strength.

Zinc Bar vs Zinc Wire Infographic

materialdif.com

materialdif.com