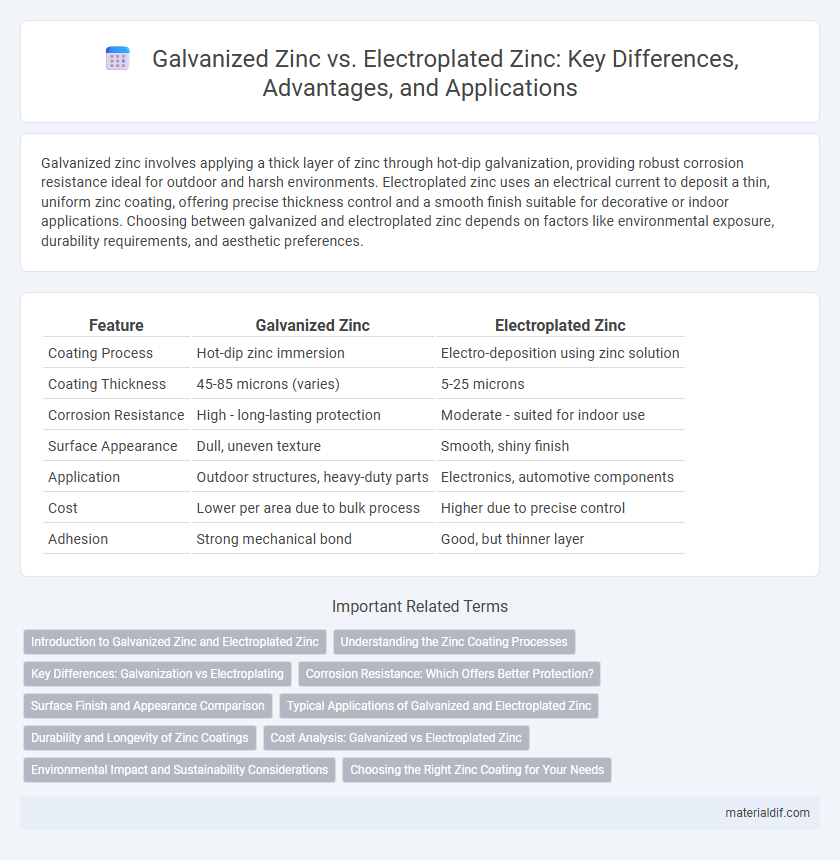

Galvanized zinc involves applying a thick layer of zinc through hot-dip galvanization, providing robust corrosion resistance ideal for outdoor and harsh environments. Electroplated zinc uses an electrical current to deposit a thin, uniform zinc coating, offering precise thickness control and a smooth finish suitable for decorative or indoor applications. Choosing between galvanized and electroplated zinc depends on factors like environmental exposure, durability requirements, and aesthetic preferences.

Table of Comparison

| Feature | Galvanized Zinc | Electroplated Zinc |

|---|---|---|

| Coating Process | Hot-dip zinc immersion | Electro-deposition using zinc solution |

| Coating Thickness | 45-85 microns (varies) | 5-25 microns |

| Corrosion Resistance | High - long-lasting protection | Moderate - suited for indoor use |

| Surface Appearance | Dull, uneven texture | Smooth, shiny finish |

| Application | Outdoor structures, heavy-duty parts | Electronics, automotive components |

| Cost | Lower per area due to bulk process | Higher due to precise control |

| Adhesion | Strong mechanical bond | Good, but thinner layer |

Introduction to Galvanized Zinc and Electroplated Zinc

Galvanized zinc coating involves hot-dipping steel or iron into molten zinc, creating a thick, durable layer that provides excellent corrosion resistance and longevity in harsh environments. Electroplated zinc, produced through an electrolytic process, deposits a thinner zinc layer on metal surfaces, offering improved aesthetics and moderate corrosion protection ideal for indoor applications. Both methods utilize zinc's sacrificial properties to protect the underlying metal, but galvanized zinc is preferred for heavy-duty outdoor use, while electroplated zinc suits lighter, decorative purposes.

Understanding the Zinc Coating Processes

Galvanized zinc coatings are applied through a hot-dip process where steel is immersed in molten zinc, creating a robust, thick layer that provides superior corrosion resistance and durability. Electroplated zinc involves depositing a thin zinc layer onto the metal surface using an electrical current in a controlled electrolyte bath, offering precise thickness control and an aesthetically smooth finish. Understanding these coating processes is crucial for selecting the right zinc protection method based on environmental exposure, mechanical wear, and appearance requirements.

Key Differences: Galvanization vs Electroplating

Galvanized zinc coating involves a hot-dip process where steel is immersed in molten zinc, creating a thick, durable layer that offers robust corrosion resistance and longevity. Electroplated zinc uses an electrochemical deposition method, applying a thinner, more uniform zinc layer that provides moderate protection and a smoother finish ideal for aesthetic applications. The primary difference lies in the coating thickness and durability, with galvanization suited for heavy-duty protection and electroplating preferred for precision and decorative purposes.

Corrosion Resistance: Which Offers Better Protection?

Galvanized zinc coating provides superior corrosion resistance compared to electroplated zinc due to its thicker, more durable layer of zinc applied through hot-dip galvanizing, which offers long-lasting protection even in harsh environments. Electroplated zinc, while providing a smoother and more uniform finish, typically has a thinner coating that is more susceptible to wear and corrosion over time. For applications requiring robust protection against rust and environmental damage, galvanized zinc is generally the preferred choice.

Surface Finish and Appearance Comparison

Galvanized zinc coatings typically exhibit a thicker, rougher surface finish due to the hot-dip process, resulting in a dull, spangled appearance that enhances corrosion resistance. Electroplated zinc provides a thinner, smoother, and more uniform finish with a bright, shiny look ideal for decorative applications but with comparatively lower corrosion protection. Surface finish differences directly influence the visual appeal and durability, making galvanized zinc preferable for industrial use and electroplated zinc favored in consumer goods.

Typical Applications of Galvanized and Electroplated Zinc

Galvanized zinc is commonly used for outdoor construction materials such as roofing, fencing, and automotive parts due to its thick, corrosion-resistant coating that withstands harsh environmental conditions. Electroplated zinc is typically applied to small hardware components, electronic parts, and fasteners where precision coating and enhanced surface finish are required. Both methods extend the lifespan of metal products but are chosen based on application-specific durability and aesthetic needs.

Durability and Longevity of Zinc Coatings

Galvanized zinc coatings offer superior durability and longevity compared to electroplated zinc due to their thicker, more uniform protective layer formed through hot-dip galvanizing processes. This thicker coating provides enhanced resistance to corrosion, abrasion, and environmental wear, extending the lifespan of treated steel components significantly. Electroplated zinc coatings, being thinner and more susceptible to wear, are less effective in providing long-term protection in harsh or outdoor environments.

Cost Analysis: Galvanized vs Electroplated Zinc

Galvanized zinc coating typically offers a more cost-effective solution for large-scale applications due to its thicker layer and longer-lasting corrosion resistance, reducing maintenance expenses over time. Electroplated zinc, while generally more expensive per unit, provides a smoother finish and is preferred for smaller components requiring precision and aesthetic appeal. Budget considerations often favor galvanized zinc for infrastructure projects where durability outweighs cosmetic factors.

Environmental Impact and Sustainability Considerations

Galvanized zinc coatings provide superior corrosion resistance and longevity compared to electroplated zinc, reducing the frequency of reapplications and thus minimizing environmental waste. The hot-dip galvanizing process typically consumes more energy but results in thicker, more durable coatings, leading to better sustainability over the product lifecycle. Electroplated zinc uses less material and energy initially but often requires more frequent maintenance or replacement, increasing long-term environmental impact.

Choosing the Right Zinc Coating for Your Needs

Galvanized zinc coatings provide a thicker, more durable layer of protection ideal for outdoor and high-corrosion environments, ensuring long-lasting rust resistance. Electroplated zinc offers a thinner, more precise coating suitable for decorative applications and indoor use where corrosion exposure is limited. Selecting the right zinc coating depends on balancing durability requirements, environmental conditions, and aesthetic preferences for efficient metal protection.

Galvanized Zinc vs Electroplated Zinc Infographic

materialdif.com

materialdif.com