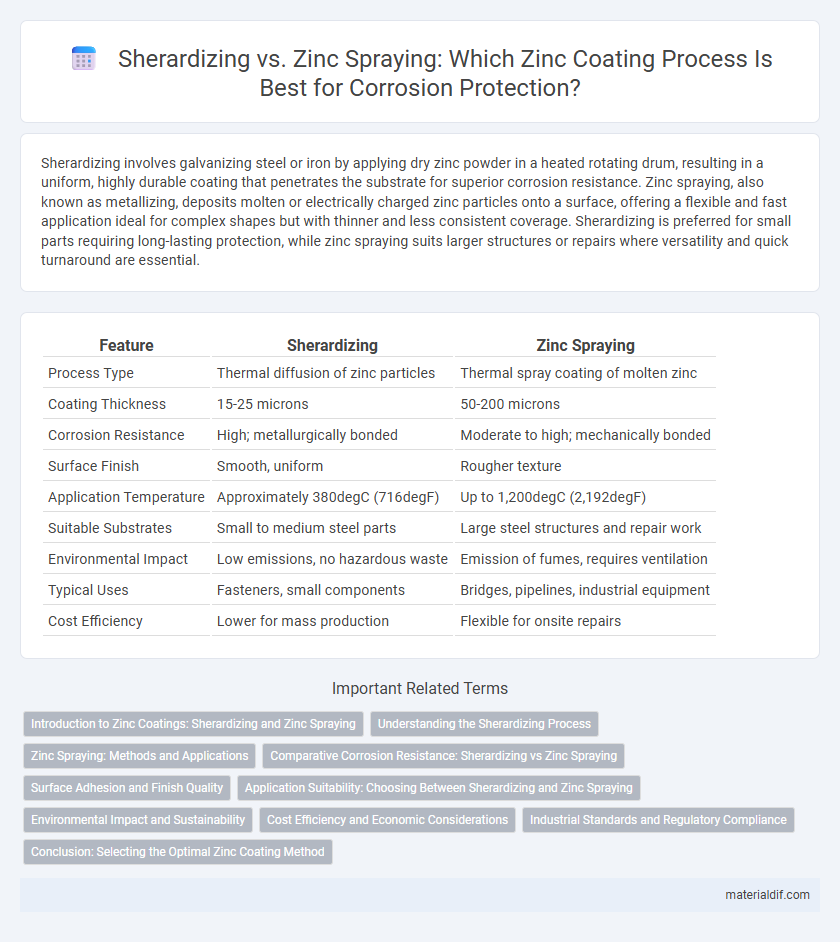

Sherardizing involves galvanizing steel or iron by applying dry zinc powder in a heated rotating drum, resulting in a uniform, highly durable coating that penetrates the substrate for superior corrosion resistance. Zinc spraying, also known as metallizing, deposits molten or electrically charged zinc particles onto a surface, offering a flexible and fast application ideal for complex shapes but with thinner and less consistent coverage. Sherardizing is preferred for small parts requiring long-lasting protection, while zinc spraying suits larger structures or repairs where versatility and quick turnaround are essential.

Table of Comparison

| Feature | Sherardizing | Zinc Spraying |

|---|---|---|

| Process Type | Thermal diffusion of zinc particles | Thermal spray coating of molten zinc |

| Coating Thickness | 15-25 microns | 50-200 microns |

| Corrosion Resistance | High; metallurgically bonded | Moderate to high; mechanically bonded |

| Surface Finish | Smooth, uniform | Rougher texture |

| Application Temperature | Approximately 380degC (716degF) | Up to 1,200degC (2,192degF) |

| Suitable Substrates | Small to medium steel parts | Large steel structures and repair work |

| Environmental Impact | Low emissions, no hazardous waste | Emission of fumes, requires ventilation |

| Typical Uses | Fasteners, small components | Bridges, pipelines, industrial equipment |

| Cost Efficiency | Lower for mass production | Flexible for onsite repairs |

Introduction to Zinc Coatings: Sherardizing and Zinc Spraying

Zinc coatings provide effective corrosion protection by forming a barrier and sacrificial layer on steel surfaces. Sherardizing is a dry thermal diffusion process where zinc powder is heated with steel components, resulting in a uniform, metallurgically bonded coating with excellent wear resistance. Zinc spraying, also known as metallizing, involves projecting molten zinc onto surfaces, offering a thicker and more flexible coating ideal for complex shapes and repair work.

Understanding the Sherardizing Process

Sherardizing is a heat-diffusion zinc coating process that involves tumbling steel parts in a closed rotating drum with zinc powder at temperatures between 300-400degC, creating a uniform, corrosion-resistant layer. This method produces a metallurgically bonded coating superior in adhesion and wear resistance compared to Zinc Spraying, which applies molten zinc via thermal spray techniques. Understanding Sherardizing highlights its ability to coat complex geometries evenly without distortion, making it ideal for small to medium-sized components requiring enhanced durability.

Zinc Spraying: Methods and Applications

Zinc spraying, also known as metallizing, involves applying molten zinc onto metal surfaces using thermal spray techniques such as flame spraying or arc spraying, creating a protective zinc coating against corrosion. This method is widely used in industries like construction, automotive, and marine applications where precise, localized corrosion protection is required on large structures or repair areas. Zinc spraying offers advantages in thickness control, adhesion strength, and the ability to coat complex geometries, making it a versatile choice compared to sherardizing, which is better suited for bulk treatment of small components.

Comparative Corrosion Resistance: Sherardizing vs Zinc Spraying

Sherardizing provides a uniform, metallurgically bonded zinc coating that offers superior corrosion resistance and durability compared to zinc spraying, which deposits a loose, mechanically bonded layer prone to flaking and less effective in harsh environments. The diffusion process in sherardizing enhances coating adhesion and extends protection to intricate geometries, while zinc spraying typically requires additional sealing for optimal performance. In industrial applications demanding long-term corrosion protection, sherardizing demonstrates greater resistance against oxidation and environmental degradation than zinc spraying.

Surface Adhesion and Finish Quality

Sherardizing involves diffusing zinc into the steel surface through a heat treatment process, resulting in superior surface adhesion and a uniform, smooth finish resistant to flaking and corrosion. Zinc spraying applies molten or arc-sprayed zinc particles onto substrates, often leading to a rougher finish with lower bond strength and potential for peeling under mechanical stress. The metallurgical bonding in Sherardizing outperforms the mechanical bond of Zinc spraying, providing enhanced durability and long-term corrosion protection.

Application Suitability: Choosing Between Sherardizing and Zinc Spraying

Sherardizing excels in applying a uniform, corrosion-resistant zinc coating on small to medium-sized steel parts through a high-temperature diffusion process, making it ideal for intricate components requiring long-lasting protection. Zinc spraying, also known as thermal spraying, is more suitable for larger or fixed structures where rapid onsite application and versatile thickness control are necessary. Selecting between Sherardizing and Zinc spraying depends on factors like part size, desired coating uniformity, environmental conditions, and specific corrosion resistance requirements.

Environmental Impact and Sustainability

Sherardizing offers a more environmentally sustainable alternative to zinc spraying by utilizing a closed-loop process that minimizes airborne emissions and waste generation. Zinc spraying often releases zinc oxide particles and solvents into the atmosphere, contributing to pollution and requiring extensive ventilation and protective measures. The eco-friendliness of sherardizing is enhanced by its lower energy consumption and the recyclability of zinc residues, aligning with green manufacturing practices.

Cost Efficiency and Economic Considerations

Sherardizing offers superior cost efficiency over zinc spraying by providing a durable, uniform coating that reduces maintenance expenses and extends metal lifespan. Zinc spraying involves higher recurring costs due to frequent reapplications and potential surface preparation requirements. Evaluating economic considerations, sherardizing's initial investment is offset by long-term savings in corrosion protection and reduced labor costs.

Industrial Standards and Regulatory Compliance

Sherardizing complies with ASTM B695 and offers uniform zinc coating thickness, meeting industrial standards for corrosion resistance in automotive and aerospace sectors. Zinc spraying adheres to SSPC standards, such as SSPC-Paint 20, ensuring compliance for protective coatings in structural steel applications. Regulatory compliance for both methods includes adherence to EPA and OSHA guidelines for environmental emissions and worker safety during application.

Conclusion: Selecting the Optimal Zinc Coating Method

Sherardizing offers a uniform, metallurgically bonded zinc coating ideal for small parts requiring high corrosion resistance and dimensional stability. Zinc spraying provides a versatile, thick layer suitable for large or irregularly shaped components where rapid application is essential. Choosing between Sherardizing and Zinc Spraying depends on factors such as component size, desired coating thickness, environmental exposure, and cost-efficiency for optimal corrosion protection.

Sherardizing vs Zinc Spraying Infographic

materialdif.com

materialdif.com