Mechanical plating provides a uniform, environmentally friendly coating process ideal for complex parts, offering excellent corrosion resistance without the use of hazardous chemicals. Electroplating, while capable of producing a highly conductive and aesthetically appealing finish, often involves toxic chemicals and requires electrical power, making it less suitable for intricate geometries. Choosing between mechanical plating and electroplating depends on factors like part complexity, environmental impact, and desired coating properties.

Table of Comparison

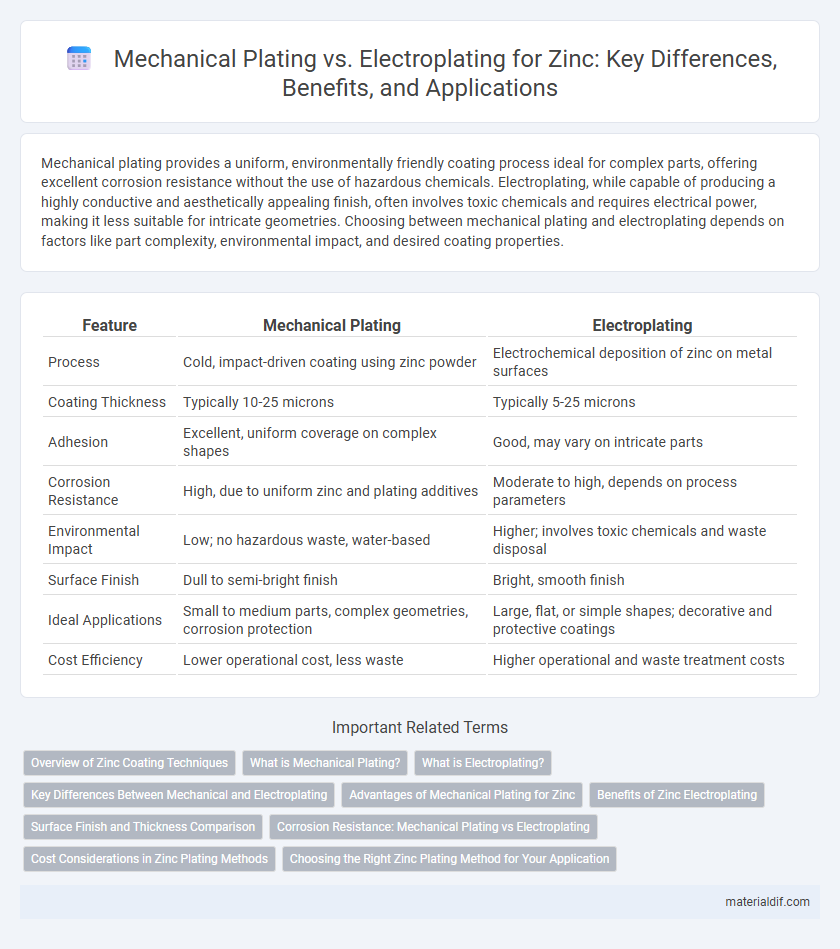

| Feature | Mechanical Plating | Electroplating |

|---|---|---|

| Process | Cold, impact-driven coating using zinc powder | Electrochemical deposition of zinc on metal surfaces |

| Coating Thickness | Typically 10-25 microns | Typically 5-25 microns |

| Adhesion | Excellent, uniform coverage on complex shapes | Good, may vary on intricate parts |

| Corrosion Resistance | High, due to uniform zinc and plating additives | Moderate to high, depends on process parameters |

| Environmental Impact | Low; no hazardous waste, water-based | Higher; involves toxic chemicals and waste disposal |

| Surface Finish | Dull to semi-bright finish | Bright, smooth finish |

| Ideal Applications | Small to medium parts, complex geometries, corrosion protection | Large, flat, or simple shapes; decorative and protective coatings |

| Cost Efficiency | Lower operational cost, less waste | Higher operational and waste treatment costs |

Overview of Zinc Coating Techniques

Mechanical plating applies zinc coatings by tumbling parts with zinc powder and media, forming a uniform, corrosion-resistant layer without heat or electricity. Electroplating uses an electric current to deposit zinc ions from a solution onto a metal substrate, enabling precise control over thickness and adhesion. Both techniques enhance steel durability, with mechanical plating favored for intricate shapes and electroplating for smooth, high-precision finishes.

What is Mechanical Plating?

Mechanical plating is a cold process that applies zinc coatings by tumbling parts with metal powder and glass beads, creating a uniform, corrosion-resistant layer without heat. This technique avoids thermal distortion and hydrogen embrittlement often associated with electroplating, making it ideal for intricate or delicate components. Mechanical plating provides superior adhesion and uniform coverage, enhancing the durability of zinc-coated parts in automotive, aerospace, and industrial applications.

What is Electroplating?

Electroplating is a metal finishing process that uses an electric current to deposit a thin layer of zinc onto a substrate, enhancing corrosion resistance and surface appearance. This technique provides precise control over coating thickness and uniformity, making it ideal for complex shapes and delicate components. Compared to mechanical plating, electroplating achieves superior adhesion and a smoother, more consistent finish.

Key Differences Between Mechanical and Electroplating

Mechanical plating deposits zinc through a cold-welding process using small metal particles, creating a non-electrolytic, environmentally friendly coating resistant to hydrogen embrittlement. Electroplating applies zinc via an electrically driven chemical reaction, producing a uniform, corrosion-resistant layer but often requires extensive surface preparation and generates hazardous waste. Mechanical plating excels in coating complex geometries without heat, whereas electroplating delivers a finer, more consistent finish suited for decorative and precision applications.

Advantages of Mechanical Plating for Zinc

Mechanical plating provides superior corrosion resistance for zinc-coated parts by creating a uniform and dense zinc layer that effectively shields steel substrates from rust. This method minimizes hydrogen embrittlement risk compared to electroplating, ensuring enhanced durability for high-strength steel components. Furthermore, mechanical plating operates at ambient temperatures, reducing thermal distortion and enabling consistent coating thickness on complex geometries.

Benefits of Zinc Electroplating

Zinc electroplating provides superior corrosion resistance by forming a uniform, tightly bonded layer that effectively protects steel substrates from rust and environmental damage. This method offers enhanced finish quality with greater control over coating thickness and appearance, resulting in improved durability and aesthetic appeal. The process also delivers better adhesion and the ability to easily incorporate passivation treatments, boosting long-term performance in industrial and automotive applications.

Surface Finish and Thickness Comparison

Mechanical plating of zinc produces a uniform, textured surface finish with a controlled thickness typically ranging from 10 to 25 microns, offering good corrosion resistance without hydrogen embrittlement. Electroplating zinc provides a smoother, shinier surface finish with a thickness that can vary between 5 to 30 microns, allowing for precise control but requiring additional post-treatment to prevent cracks. Both methods enhance surface durability, but mechanical plating is favored for thicker, stress-free coatings, while electroplating excels in achieving finer, more decorative finishes.

Corrosion Resistance: Mechanical Plating vs Electroplating

Mechanical plating offers superior corrosion resistance by applying a uniform zinc coating through impact-driven deformation, minimizing hydrogen embrittlement risks common in electroplating. Electroplating provides a thinner zinc layer with excellent adhesion but can introduce micro-cracks, reducing long-term corrosion protection. Zinc coatings from mechanical plating generally extend substrate lifespan in harsh environments due to their enhanced barrier and sacrificial properties.

Cost Considerations in Zinc Plating Methods

Mechanical plating typically involves lower energy consumption and reduced chemical usage compared to electroplating, resulting in lower operational costs for zinc coating applications. Electroplating requires significant investment in electrical power and chemical baths, increasing expenses related to maintenance, waste treatment, and environmental compliance. Cost effectiveness of mechanical plating makes it preferable for large-scale production where minimizing total expenses in zinc plating methods is critical.

Choosing the Right Zinc Plating Method for Your Application

Mechanical plating offers uniform zinc coating with minimal hydrogen embrittlement risk, ideal for small, complex parts requiring corrosion resistance. Electroplating provides precise thickness control and superior adhesion, suitable for larger components needing enhanced wear and aesthetic finishes. Selecting the appropriate zinc plating method depends on factors like part geometry, desired corrosion protection level, and production scale.

Mechanical Plating vs Electroplating Infographic

materialdif.com

materialdif.com