Zinc die casting produces complex, high-precision components with excellent surface finish by injecting molten zinc into reusable steel molds, ideal for intricate pet accessory parts requiring tight tolerances. Zinc extrusion shapes zinc billets by forcing them through a die, creating long, uniform profiles suitable for structural pet enclosures or frames with consistent cross-sections. Each process offers distinct advantages in strength, detail, and production efficiency for various zinc pet product applications.

Table of Comparison

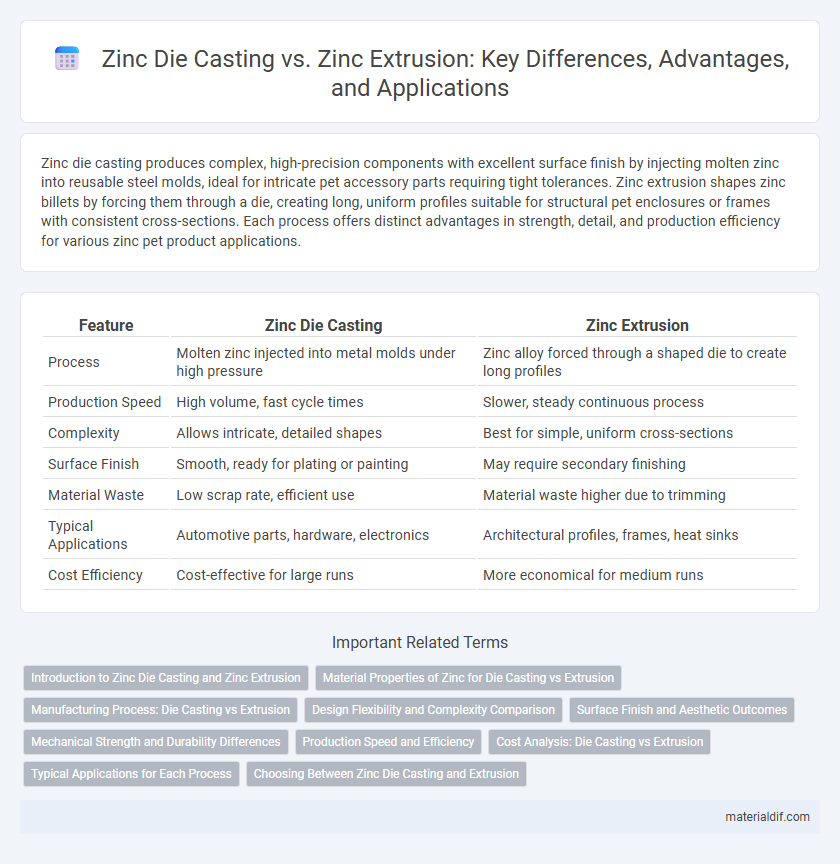

| Feature | Zinc Die Casting | Zinc Extrusion |

|---|---|---|

| Process | Molten zinc injected into metal molds under high pressure | Zinc alloy forced through a shaped die to create long profiles |

| Production Speed | High volume, fast cycle times | Slower, steady continuous process |

| Complexity | Allows intricate, detailed shapes | Best for simple, uniform cross-sections |

| Surface Finish | Smooth, ready for plating or painting | May require secondary finishing |

| Material Waste | Low scrap rate, efficient use | Material waste higher due to trimming |

| Typical Applications | Automotive parts, hardware, electronics | Architectural profiles, frames, heat sinks |

| Cost Efficiency | Cost-effective for large runs | More economical for medium runs |

Introduction to Zinc Die Casting and Zinc Extrusion

Zinc die casting involves injecting molten zinc into high-precision steel molds under high pressure, producing complex, detailed parts with excellent surface finishes and tight tolerances. Zinc extrusion pushes heated zinc billets through a shaped die, creating long, uniform cross-sectional profiles ideal for structural components and frames. Both processes leverage zinc's strength, corrosion resistance, and low melting point but serve different manufacturing needs based on design complexity and production volume.

Material Properties of Zinc for Die Casting vs Extrusion

Zinc die casting offers superior dimensional accuracy and intricate detail due to its low melting point and excellent fluidity, enabling complex shapes and thin walls. Zinc extrusion produces materials with higher tensile strength and better mechanical properties, making it suitable for structural applications requiring durability. Both processes utilize zinc's corrosion resistance and thermal conductivity, but die casting prioritizes form precision while extrusion emphasizes strength and uniformity.

Manufacturing Process: Die Casting vs Extrusion

Zinc die casting involves injecting molten zinc into a steel mold under high pressure, enabling the production of complex, precise components with excellent surface finish and minimal machining. Zinc extrusion pushes heated zinc alloy through a shaped die, creating long, uniform profiles ideal for structural and architectural applications with consistent cross-sections. Die casting excels in detailed geometries and mass production efficiency, while extrusion offers superior strength and design flexibility for linear parts.

Design Flexibility and Complexity Comparison

Zinc die casting offers superior design flexibility, enabling intricate shapes and fine details with tight tolerances due to its molten metal injection process. In contrast, zinc extrusion produces simpler, uniform profiles by forcing metal through a die, limiting complexity but allowing for consistent cross-sectional designs. Die casting supports complex geometries unsuitable for extrusion, making it ideal for components requiring detailed features and varied thicknesses.

Surface Finish and Aesthetic Outcomes

Zinc die casting offers superior surface finish with intricate detail and smooth, uniform textures ideal for high-quality aesthetic applications. Zinc extrusion typically results in coarser surfaces requiring secondary machining or finishing to meet visual standards. The die casting process enables complex shapes with fine features, enhancing the overall appearance and paint adhesion compared to extrusion.

Mechanical Strength and Durability Differences

Zinc die casting offers superior mechanical strength and durability due to its fine-grained microstructure and uniform density, making it ideal for complex shapes and high-stress applications. In contrast, zinc extrusion produces components with enhanced ductility and impact resistance but generally lower tensile strength compared to die-cast parts. The choice between zinc die casting and extrusion depends on the specific mechanical requirements, with die casting preferred for rigidity and extrusion favored for flexibility and toughness.

Production Speed and Efficiency

Zinc die casting offers significantly faster production speeds compared to zinc extrusion due to its ability to create complex shapes in a single, rapid molding process. The high automation level in die casting reduces labor costs and enhances efficiency, making it ideal for mass production. In contrast, zinc extrusion requires longer cycle times and additional machining, resulting in slower throughput and increased operational complexity.

Cost Analysis: Die Casting vs Extrusion

Zinc die casting typically has higher initial tooling costs due to mold fabrication but offers lower per-unit costs for large production volumes, making it cost-effective for mass manufacturing. Zinc extrusion involves less expensive tooling but results in higher per-unit costs and limited complexity in part design, suitable for smaller production runs or simpler shapes. Evaluating cost efficiency between zinc die casting and zinc extrusion depends on production volume, part complexity, and precision requirements.

Typical Applications for Each Process

Zinc die casting is commonly used in automotive components, electrical housings, and hardware fittings due to its ability to produce complex shapes with high precision and excellent surface finishes. Zinc extrusion is preferred for architectural trim, window frames, and heat sinks where long, uniform cross-sectional profiles are required with good mechanical strength. Both processes leverage zinc's corrosion resistance and durability but cater to different design and production needs based on part complexity and geometric requirements.

Choosing Between Zinc Die Casting and Extrusion

Zinc die casting offers superior precision and complex geometries compared to zinc extrusion, making it ideal for intricate components requiring tight tolerances. Zinc extrusion provides enhanced structural strength and is more suitable for producing long, uniform profiles with consistent cross-sections. Choosing between zinc die casting and extrusion depends on the specific application's design complexity, production volume, and mechanical property requirements.

Zinc Die Casting vs Zinc Extrusion Infographic

materialdif.com

materialdif.com