Sherardizing offers superior corrosion resistance for zinc-coated pet products by applying zinc through a controlled heat process, creating a uniform, metallurgically bonded layer. Spraying zinc provides a quicker, more flexible coating method but tends to result in thinner, less durable layers prone to wear and environmental damage. Choosing Sherardizing ensures long-lasting protection, especially in demanding or outdoor environments where zinc pet components require enhanced durability.

Table of Comparison

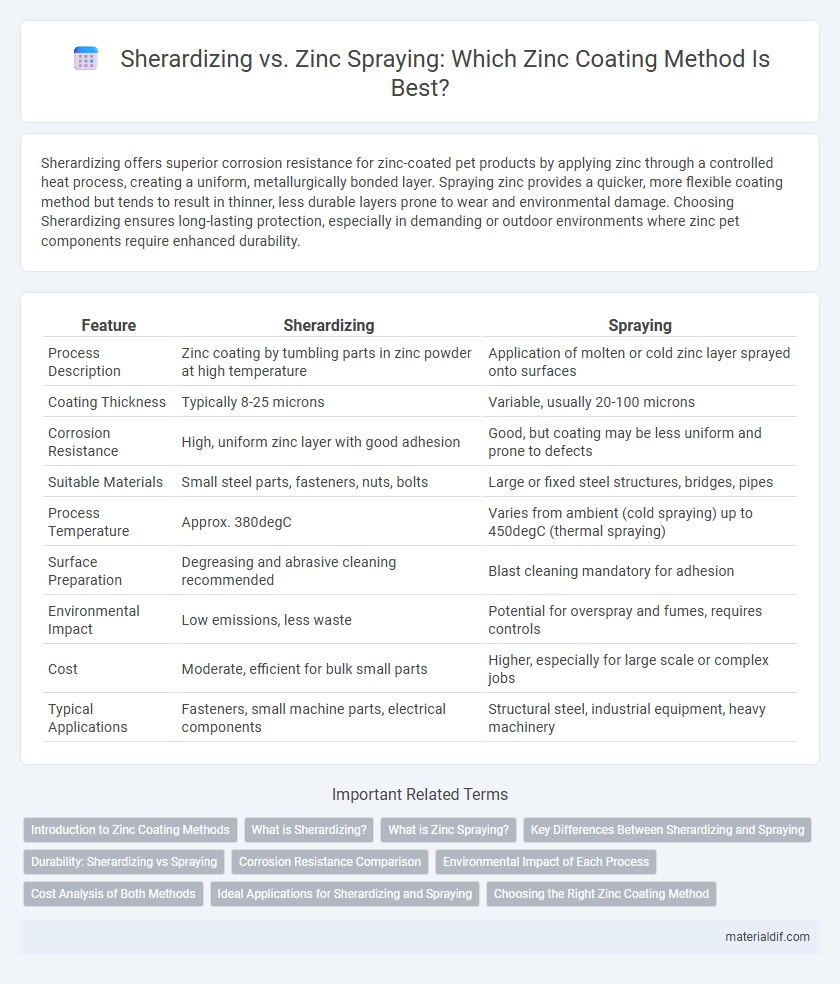

| Feature | Sherardizing | Spraying |

|---|---|---|

| Process Description | Zinc coating by tumbling parts in zinc powder at high temperature | Application of molten or cold zinc layer sprayed onto surfaces |

| Coating Thickness | Typically 8-25 microns | Variable, usually 20-100 microns |

| Corrosion Resistance | High, uniform zinc layer with good adhesion | Good, but coating may be less uniform and prone to defects |

| Suitable Materials | Small steel parts, fasteners, nuts, bolts | Large or fixed steel structures, bridges, pipes |

| Process Temperature | Approx. 380degC | Varies from ambient (cold spraying) up to 450degC (thermal spraying) |

| Surface Preparation | Degreasing and abrasive cleaning recommended | Blast cleaning mandatory for adhesion |

| Environmental Impact | Low emissions, less waste | Potential for overspray and fumes, requires controls |

| Cost | Moderate, efficient for bulk small parts | Higher, especially for large scale or complex jobs |

| Typical Applications | Fasteners, small machine parts, electrical components | Structural steel, industrial equipment, heavy machinery |

Introduction to Zinc Coating Methods

Sherardizing is a thermal diffusion process that applies a thin, uniform zinc coating by heating steel parts in a closed drum with zinc dust, ensuring excellent corrosion resistance. Spraying involves applying molten or atomized zinc particles onto the surface, allowing for thicker coatings and suitability for large or complex structures. Both methods enhance steel durability but differ in application technique, coating thickness, and surface finish quality.

What is Sherardizing?

Sherardizing is a thermal diffusion process that applies a uniform zinc coating to metal surfaces by heating metal parts in a sealed rotating drum with zinc powder. This method creates a highly durable, corrosion-resistant layer that penetrates the surface, making it ideal for intricate shapes and small parts. Unlike spraying, sherardizing produces a metallurgically bonded coating, enhancing adhesion and wear resistance without risk of flaking or peeling.

What is Zinc Spraying?

Zinc spraying is a thermal metal spraying process that applies molten zinc particles onto a prepared steel surface to provide corrosion protection. This technique creates a metallurgically bonded zinc coating that acts as a sacrificial barrier, preventing rust and extending the lifespan of steel structures. Unlike sherardizing, which involves diffusing zinc into the steel substrate through heat treatment, zinc spraying offers a versatile and durable coating suitable for irregular shapes and large surfaces.

Key Differences Between Sherardizing and Spraying

Sherardizing utilizes a closed rotating drum with zinc dust heated to around 380degC, creating a diffusion bond that offers superior corrosion resistance and uniform coating thickness on complex shapes. Spraying involves the mechanical application of molten zinc or zinc particles onto the surface, resulting in a thicker yet less consistent layer prone to potential adhesion issues. Sherardizing excels in coating internal surfaces and intricate geometries, whereas spraying provides faster coverage suited for larger, less detailed components.

Durability: Sherardizing vs Spraying

Sherardizing provides superior durability compared to spraying due to its metallurgical bonding process, which ensures uniform zinc diffusion into the metal surface, enhancing corrosion resistance. Spraying, while quicker and more flexible, produces a coating that is mechanically bonded and more prone to chipping, reducing long-term protection in harsh environments. Sherardized steel typically offers extended service life in industrial applications, outperforming sprayed coatings in wear and weather resistance.

Corrosion Resistance Comparison

Sherardizing provides superior corrosion resistance compared to zinc spraying due to its uniform zinc diffusion into the substrate, forming a tightly bonded, hard zinc-iron alloy layer that protects against oxidation and corrosion. Zinc spraying offers a thicker but less adherent zinc coating prone to mechanical damage and uneven coverage, leading to potential localized corrosion. The metallurgical bond achieved in Sherardizing significantly enhances long-term durability in harsh environments compared to the mechanical adhesion of sprayed zinc.

Environmental Impact of Each Process

Sherardizing minimizes environmental impact by using a closed, powdered zinc process that reduces emissions and waste compared to spraying, which often releases airborne zinc particles and volatile organic compounds (VOCs). Spraying can lead to higher contamination of surrounding air and soil, increasing the need for remediation and protective measures. Sherardizing's controlled, furnace-based environment results in lower energy consumption and fewer pollutants, positioning it as a more sustainable zinc coating method.

Cost Analysis of Both Methods

Sherardizing typically incurs higher initial equipment and operational costs due to its closed drum process and temperature control requirements, but it offers superior coating uniformity and corrosion resistance, potentially reducing long-term maintenance expenses. Spraying involves lower upfront investment and faster application, yet it may lead to uneven coverage and higher material wastage, increasing overall expenditure through rework and touch-ups. Evaluating total cost effectiveness requires considering production volume, corrosion demands, and lifecycle costs associated with zinc coating quality.

Ideal Applications for Sherardizing and Spraying

Sherardizing is ideal for coating small, complex metal parts such as fasteners, nuts, and bolts, providing uniform zinc diffusion for enhanced corrosion resistance and durability. Spraying suits larger structures and surfaces where thick, localized zinc coatings are needed, commonly used in steel frameworks and industrial equipment for rapid corrosion protection. Selecting between sherardizing and spraying depends on part size, geometry, and desired coating thickness to optimize zinc application effectiveness.

Choosing the Right Zinc Coating Method

Choosing the right zinc coating method depends on the application requirements and environmental conditions; sherardizing offers uniform, corrosion-resistant coatings ideal for complex geometries, while spraying provides thicker, more localized protection suited for heavy-duty industrial parts. Sherardizing involves diffusing zinc onto steel surfaces through a heat and tumbler process, enhancing adhesion and durability without altering dimensions. Zinc spraying, or thermal spraying, deposits molten zinc particles onto substrates, allowing for rapid, customizable thickness but may require additional finishing steps to ensure longevity.

Sherardizing vs Spraying Infographic

materialdif.com

materialdif.com