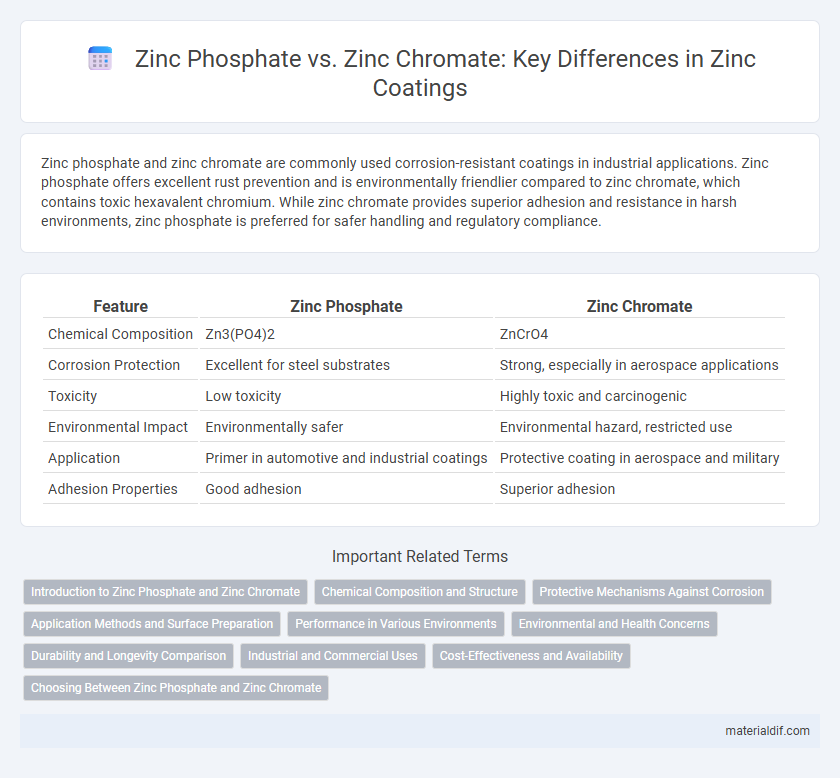

Zinc phosphate and zinc chromate are commonly used corrosion-resistant coatings in industrial applications. Zinc phosphate offers excellent rust prevention and is environmentally friendlier compared to zinc chromate, which contains toxic hexavalent chromium. While zinc chromate provides superior adhesion and resistance in harsh environments, zinc phosphate is preferred for safer handling and regulatory compliance.

Table of Comparison

| Feature | Zinc Phosphate | Zinc Chromate |

|---|---|---|

| Chemical Composition | Zn3(PO4)2 | ZnCrO4 |

| Corrosion Protection | Excellent for steel substrates | Strong, especially in aerospace applications |

| Toxicity | Low toxicity | Highly toxic and carcinogenic |

| Environmental Impact | Environmentally safer | Environmental hazard, restricted use |

| Application | Primer in automotive and industrial coatings | Protective coating in aerospace and military |

| Adhesion Properties | Good adhesion | Superior adhesion |

Introduction to Zinc Phosphate and Zinc Chromate

Zinc phosphate and zinc chromate are both inorganic chemical compounds widely used as corrosion-resistant coatings in industrial applications. Zinc phosphate serves primarily as an environmentally friendly, non-toxic anti-corrosion primer that enhances paint adhesion on metal surfaces. Zinc chromate, containing hexavalent chromium, is a highly effective but more hazardous corrosion inhibitor, often restricted due to its toxicity and environmental impact.

Chemical Composition and Structure

Zinc phosphate is an inorganic compound composed of zinc ions (Zn2+) combined with phosphate ions (PO43-), forming a stable, non-toxic crystalline structure often used as a corrosion-resistant coating. Zinc chromate contains zinc ions and chromate ions (CrO42-), characterized by its hexavalent chromium content, which provides strong anti-corrosive properties but raises environmental and health concerns due to chromium toxicity. The phosphate-based zinc compound offers chemical stability and environmental safety, whereas zinc chromate's structure delivers superior durability at the cost of increased chemical hazard.

Protective Mechanisms Against Corrosion

Zinc phosphate forms a stable, insoluble layer on metal surfaces that acts as a physical barrier to prevent moisture and oxygen from reaching the substrate, thereby inhibiting corrosion. Zinc chromate provides corrosion protection by creating a passivating layer that actively suppresses electrochemical reactions through its chromate ions, offering self-healing properties in case of minor damage. Both coatings enhance corrosion resistance, but zinc chromate's inherent passivation and regenerative capabilities often result in superior long-term protection in harsh environments.

Application Methods and Surface Preparation

Zinc phosphate coatings require thorough surface cleaning, including degreasing and abrasive blasting, to ensure strong adhesion primarily in automotive and industrial corrosion protection applications. Zinc chromate, favored for its corrosion resistance in aerospace and military uses, demands meticulous surface preparation with similar cleaning methods but often includes chemical conversion treatments to enhance coating performance. Application methods for zinc phosphate typically involve immersion or spray techniques, while zinc chromate is commonly applied through spraying or brushing, tailored to complex geometries and specific environmental conditions.

Performance in Various Environments

Zinc phosphate coatings exhibit superior corrosion resistance in a variety of environments, including alkaline and mildly acidic conditions, making them ideal for automotive and industrial applications. Zinc chromate offers outstanding protection against corrosion and excellent adhesion in harsh, marine, and highly acidic atmospheres but has environmental and health concerns limiting its use. Performance in outdoor and corrosive environments favors zinc phosphate for eco-friendly applications, while zinc chromate remains prevalent where high durability and chemical resistance are critical.

Environmental and Health Concerns

Zinc phosphate is favored over zinc chromate due to its lower environmental toxicity and reduced health hazards, as zinc chromate contains hexavalent chromium, a known carcinogen that poses significant risks to respiratory health and ecosystems. Zinc phosphate serves as a safer corrosion inhibitor in coatings and primers, minimizing toxic heavy metal exposure and environmental contamination. Regulatory restrictions on chromium compounds have led to increased adoption of zinc phosphate in industrial applications to meet health and environmental safety standards.

Durability and Longevity Comparison

Zinc phosphate coatings offer excellent corrosion resistance and provide durable protection for steel surfaces, making them ideal for automotive and industrial applications with moderate exposure. Zinc chromate provides superior durability and longer lifespan due to its enhanced anti-corrosive properties, but concerns about toxicity limit its usage in modern applications. The longevity of zinc phosphate is often sufficient for most environments, while zinc chromate excels in highly corrosive conditions, balancing performance with environmental considerations.

Industrial and Commercial Uses

Zinc phosphate is widely used in industrial coatings as an anti-corrosive primer for steel structures, offering excellent adhesion and rust resistance in automotive and construction applications. Zinc chromate serves primarily as a corrosion-inhibiting coating in aerospace and heavy machinery, valued for its superior protective properties against oxidation and weathering. While zinc phosphate is favored for environmentally safer commercial uses, zinc chromate remains critical in industries demanding high-performance corrosion resistance despite its toxicity concerns.

Cost-Effectiveness and Availability

Zinc phosphate offers greater cost-effectiveness and wider availability compared to zinc chromate, making it a preferred choice in industrial coatings and corrosion resistance applications. Zinc chromate, while providing superior corrosion protection, is more expensive and less accessible due to strict environmental regulations and toxicity concerns. Manufacturers often select zinc phosphate for budget-conscious projects without compromising basic protective qualities.

Choosing Between Zinc Phosphate and Zinc Chromate

Zinc phosphate offers superior corrosion resistance with non-toxic properties, making it a preferred option for environmentally conscious applications and automotive primers. Zinc chromate provides excellent anti-corrosion performance but contains hexavalent chromium, raising health and environmental concerns that restrict its use. Selecting between zinc phosphate and zinc chromate depends on factors like desired corrosion protection, regulatory compliance, and safety requirements in industrial coatings.

Zinc phosphate vs Zinc chromate Infographic

materialdif.com

materialdif.com