Chromate conversion coatings create a protective layer by chemically reacting with zinc surfaces, providing excellent corrosion resistance and color stability ideal for automotive and aerospace applications. Zinc phosphate conversion coatings offer superior adhesion properties for subsequent painting and improved wear resistance, making them a preferred choice in heavy machinery and industrial environments. Choosing between chromate and zinc phosphate conversions depends on the desired balance of corrosion protection, adhesion, and environmental considerations.

Table of Comparison

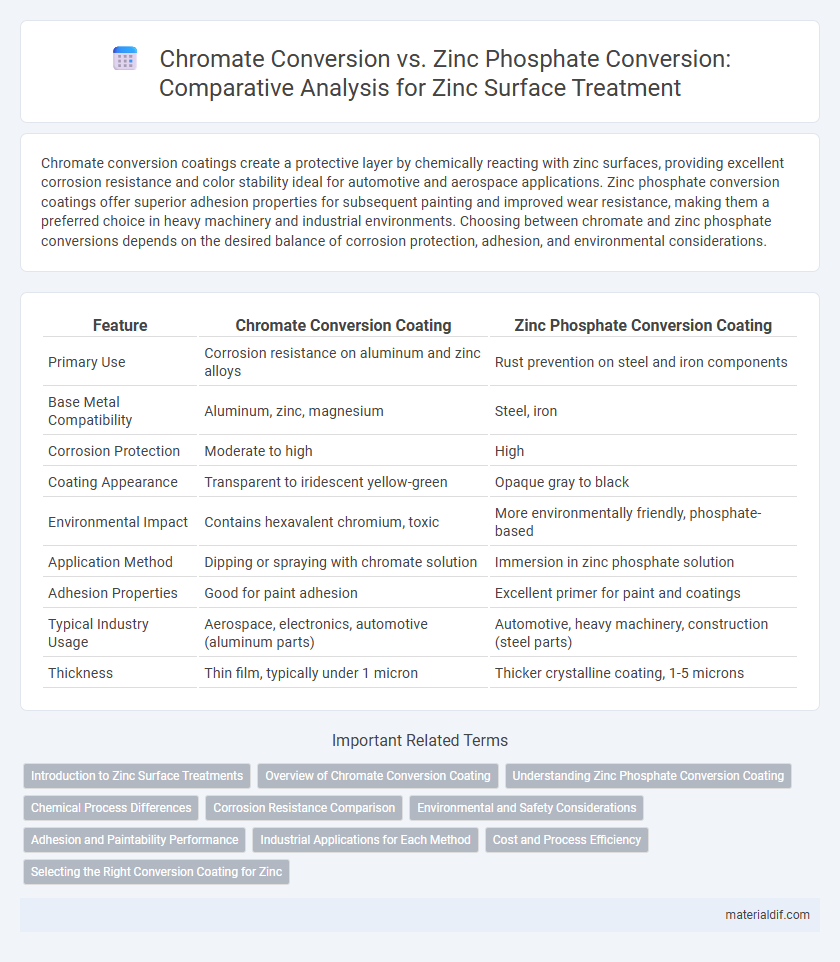

| Feature | Chromate Conversion Coating | Zinc Phosphate Conversion Coating |

|---|---|---|

| Primary Use | Corrosion resistance on aluminum and zinc alloys | Rust prevention on steel and iron components |

| Base Metal Compatibility | Aluminum, zinc, magnesium | Steel, iron |

| Corrosion Protection | Moderate to high | High |

| Coating Appearance | Transparent to iridescent yellow-green | Opaque gray to black |

| Environmental Impact | Contains hexavalent chromium, toxic | More environmentally friendly, phosphate-based |

| Application Method | Dipping or spraying with chromate solution | Immersion in zinc phosphate solution |

| Adhesion Properties | Good for paint adhesion | Excellent primer for paint and coatings |

| Typical Industry Usage | Aerospace, electronics, automotive (aluminum parts) | Automotive, heavy machinery, construction (steel parts) |

| Thickness | Thin film, typically under 1 micron | Thicker crystalline coating, 1-5 microns |

Introduction to Zinc Surface Treatments

Zinc surface treatments such as chromate conversion and zinc phosphate conversion play crucial roles in enhancing corrosion resistance and paint adhesion. Chromate conversion coatings offer excellent corrosion protection with self-healing properties, commonly used in aerospace and automotive industries. Zinc phosphate conversion provides a more environmentally friendly alternative, forming crystalline phosphate layers that improve paint adhesion and inhibit rust formation on steel and zinc substrates.

Overview of Chromate Conversion Coating

Chromate conversion coating is a chemical treatment applied to zinc surfaces to enhance corrosion resistance and paint adhesion by forming a thin, passive oxide layer rich in chromium compounds. This coating provides superior protection against oxidation and extends the lifespan of zinc-coated metals in harsh environments. Unlike zinc phosphate conversion, chromate conversion offers a more environmentally regulated process due to the use of hexavalent chromium, though it delivers higher performance in corrosion resistance.

Understanding Zinc Phosphate Conversion Coating

Zinc phosphate conversion coating provides superior corrosion resistance compared to chromate conversion by forming a crystalline phosphate layer that enhances paint adhesion and durability. This coating process involves immersing zinc alloys in a phosphoric acid-based solution, which promotes nucleation and growth of insoluble zinc phosphate crystals on the metal surface. The resulting zinc phosphate layer significantly improves protection in automotive and industrial applications, outperforming chromate treatments that rely primarily on hexavalent chromium compounds.

Chemical Process Differences

Chromate conversion coating involves the reduction of hexavalent chromium compounds, forming a protective chromate layer on zinc surfaces, whereas zinc phosphate conversion relies on chemical reaction between zinc ions and phosphate ions to produce a crystalline phosphate coating. The chromate process typically offers superior corrosion resistance through the formation of a dense, self-healing film, while zinc phosphate conversion enhances paint adhesion and provides moderate corrosion protection. Key chemical differences include the oxidative nature of chromate treatments versus the precipitation and crystallization mechanisms characteristic of zinc phosphate.

Corrosion Resistance Comparison

Chromate conversion coatings provide superior corrosion resistance on zinc due to their ability to form a dense, protective layer that inhibits oxidation and environmental degradation. Zinc phosphate conversion coatings create a crystalline phosphate layer that enhances corrosion resistance but generally offer less protection than chromate treatments, especially in harsh or highly corrosive environments. The choice between chromate and zinc phosphate conversion often depends on the required durability, environmental regulations, and the specific application conditions where corrosion resistance is critical.

Environmental and Safety Considerations

Chromate conversion coatings offer excellent corrosion resistance but involve hexavalent chromium, a toxic substance regulated under strict environmental laws due to its carcinogenic and ecological hazards. Zinc phosphate conversion is a safer alternative, providing effective corrosion protection with lower environmental impact and compliance with regulations such as RoHS and REACH. Choosing zinc phosphate conversion reduces hazardous waste generation and occupational health risks compared to chromate-based treatments.

Adhesion and Paintability Performance

Chromate conversion coatings offer superior adhesion and corrosion resistance on zinc surfaces compared to zinc phosphate conversion, enhancing paintability and ensuring long-term durability. Zinc phosphate conversion provides a more uniform crystalline layer that promotes better paint adhesion on complex geometries but may require additional sealing for optimal corrosion protection. Selecting between chromate and zinc phosphate treatments depends on the specific application requirements, balancing adhesion strength, corrosion resistance, and environmental regulations.

Industrial Applications for Each Method

Chromate conversion coatings provide excellent corrosion resistance and are widely used in aerospace and automotive industries for aluminum and zinc-plated steel components. Zinc phosphate conversion coatings enhance adhesion of subsequent paint layers and are preferred in heavy machinery and construction equipment manufacturing due to their strong anti-corrosive properties. Both methods improve durability, but chromate conversion is favored for lightweight, precision parts while zinc phosphate suits substrates requiring robust primer bonding.

Cost and Process Efficiency

Chromate conversion coating typically offers faster processing times and lower chemical usage, resulting in reduced operational costs compared to zinc phosphate conversion. Zinc phosphate conversion requires longer immersion and rinsing cycles, increasing water and energy consumption, which raises overall process expenses. Cost-efficiency analysis shows chromate conversion as favorable for high-volume zinc-plated parts due to streamlined application and lower material costs.

Selecting the Right Conversion Coating for Zinc

Choosing the right conversion coating for zinc involves comparing chromate conversion and zinc phosphate conversion, each offering unique corrosion resistance and surface adherence properties. Chromate conversion coating provides excellent rust prevention and electrical conductivity, ideal for electronic components and aerospace applications. Zinc phosphate conversion, favored in automotive and heavy machinery industries, enhances paint adhesion and provides superior wear resistance under harsh environmental conditions.

Chromate Conversion vs Zinc Phosphate Conversion Infographic

materialdif.com

materialdif.com