Rolled zinc offers a smooth, uniform surface ideal for precise architectural applications, while spun zinc provides a textured finish often used in decorative and industrial designs. Rolled zinc is produced through a cold rolling process, enhancing its strength and consistency, whereas spun zinc is shaped by spinning molten zinc into rounded or tubular forms. Choosing between rolled and spun zinc depends on the specific requirements for durability, appearance, and fabrication techniques in pet product manufacturing.

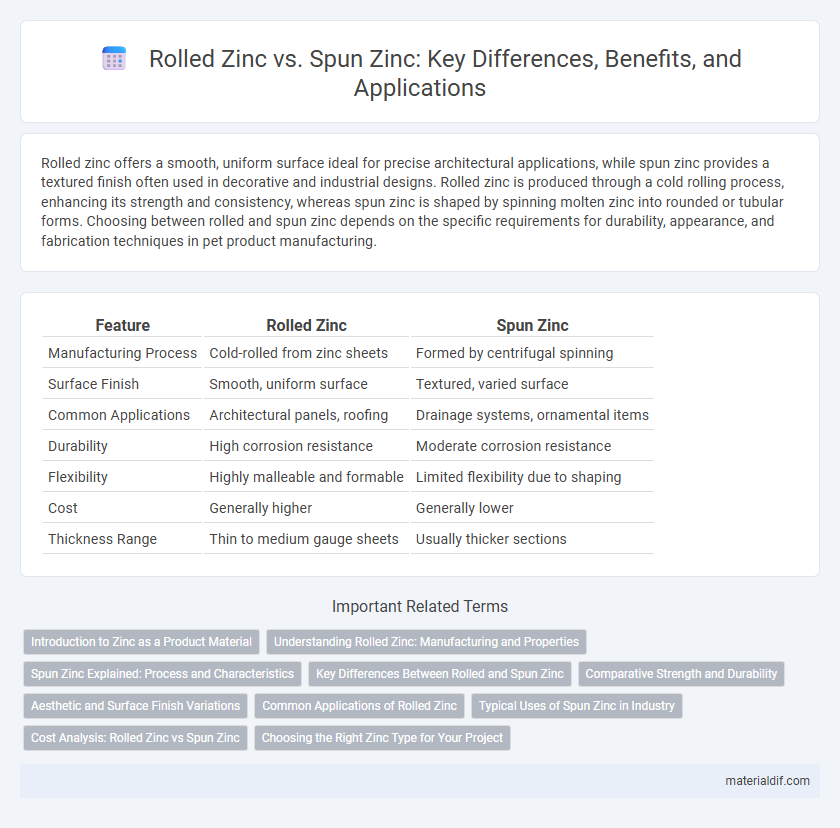

Table of Comparison

| Feature | Rolled Zinc | Spun Zinc |

|---|---|---|

| Manufacturing Process | Cold-rolled from zinc sheets | Formed by centrifugal spinning |

| Surface Finish | Smooth, uniform surface | Textured, varied surface |

| Common Applications | Architectural panels, roofing | Drainage systems, ornamental items |

| Durability | High corrosion resistance | Moderate corrosion resistance |

| Flexibility | Highly malleable and formable | Limited flexibility due to shaping |

| Cost | Generally higher | Generally lower |

| Thickness Range | Thin to medium gauge sheets | Usually thicker sections |

Introduction to Zinc as a Product Material

Rolled zinc is produced by passing zinc through rollers to create thin sheets with smooth surfaces, ideal for cladding and roofing due to its uniform thickness and excellent corrosion resistance. Spun zinc is formed by casting zinc into molds and spinning it to achieve specific shapes, often used in decorative applications and architectural components requiring custom designs. Both rolled and spun zinc provide durable, weather-resistant properties essential for long-lasting building materials.

Understanding Rolled Zinc: Manufacturing and Properties

Rolled zinc is produced by passing zinc ingots through rollers at controlled temperatures, resulting in thin, flat sheets with a consistent thickness and smooth surface ideal for construction and industrial applications. This manufacturing process aligns zinc crystals, enhancing mechanical strength and surface quality compared to spun zinc, which is shaped by centrifugal casting. The superior durability and precise dimensions of rolled zinc make it preferred for roofing, cladding, and architectural detailing.

Spun Zinc Explained: Process and Characteristics

Spun zinc is produced by melting high-purity zinc and spinning it at high speeds to form thin, uniform sheets with superior strength and corrosion resistance. This process enhances the metal's grain structure, resulting in improved durability and flexibility compared to rolled zinc. Spun zinc's fine texture and aesthetic finish make it ideal for architectural applications requiring both performance and visual appeal.

Key Differences Between Rolled and Spun Zinc

Rolled zinc features thin, flat sheets produced by passing zinc through rollers, offering uniform thickness and smooth surfaces ideal for roofing and cladding applications. Spun zinc results from molding molten zinc into shapes through centrifugal force, enabling the creation of complex, curved architectural components with enhanced durability. Key differences include manufacturing processes, surface texture, and application suitability, where rolled zinc emphasizes flat, adaptable sheets, and spun zinc allows intricate, three-dimensional designs.

Comparative Strength and Durability

Rolled zinc exhibits higher tensile strength and superior flexibility compared to spun zinc, making it more resistant to impact and structural deformation. Spun zinc, while less robust, offers enhanced corrosion resistance due to its denser grain structure developed during the spinning process. Both materials provide excellent durability for architectural applications, but rolled zinc is preferred for projects requiring increased mechanical strength and long-term resilience.

Aesthetic and Surface Finish Variations

Rolled zinc offers a smooth, uniform surface finish ideal for sleek architectural applications, while spun zinc provides a more textured, matte appearance suited for decorative elements. The aesthetic variation between rolled and spun zinc allows designers to select materials based on desired visual impact and light reflection. Rolled zinc's fine grain contrasts with spun zinc's brushed effect, enhancing versatility in zinc cladding and roofing projects.

Common Applications of Rolled Zinc

Rolled zinc is widely used in architectural cladding, roofing, and facade systems due to its excellent malleability, corrosion resistance, and aesthetic appeal. Common applications include rainwater drainage systems, such as gutters and downspouts, as well as decorative panels and flashings in both residential and commercial buildings. Its ability to be easily formed into various shapes makes rolled zinc ideal for customized design elements in modern construction.

Typical Uses of Spun Zinc in Industry

Spun zinc is commonly used in architectural applications such as roofing, gutters, and downpipes due to its excellent malleability and corrosion resistance. Its ability to be easily shaped and formed makes it ideal for decorative features and custom metalwork in construction. The material's durability and aesthetic appeal also extend its use to cladding and facades in modern building projects.

Cost Analysis: Rolled Zinc vs Spun Zinc

Rolled zinc typically incurs lower production costs due to its streamlined manufacturing process involving pressing and rolling zinc sheets, making it more cost-effective for large-scale projects. Spun zinc requires more intricate shaping and molding processes, resulting in higher labor and tooling expenses, which increases its overall price. Cost analysis reveals that rolled zinc is preferred for budget-conscious applications, while spun zinc justifies its premium price through superior design flexibility and aesthetic appeal.

Choosing the Right Zinc Type for Your Project

Rolled zinc offers a uniform thickness and smooth finish ideal for roofing and cladding applications where precision and consistency are crucial, while spun zinc is formed by centrifugal casting, resulting in unique shapes suited for decorative elements like gutters and downspouts. Selecting the right zinc type depends on the project's structural requirements and aesthetic goals, with rolled zinc preferred for large-scale, flat installations and spun zinc for customized, intricate designs. Consider factors such as durability, fabrication complexity, and cost-effectiveness to ensure optimal performance and longevity of the zinc components.

Rolled Zinc vs Spun Zinc Infographic

materialdif.com

materialdif.com