Recycled zinc offers a sustainable alternative to virgin zinc by reducing resource extraction and lowering environmental impact while maintaining comparable quality for pet product manufacturing. Virgin zinc, sourced directly from mined ore, tends to have higher purity levels but involves more energy-intensive processes and greater ecological disruption. Choosing recycled zinc supports circular economy principles and helps minimize the carbon footprint associated with zinc production in the pet industry.

Table of Comparison

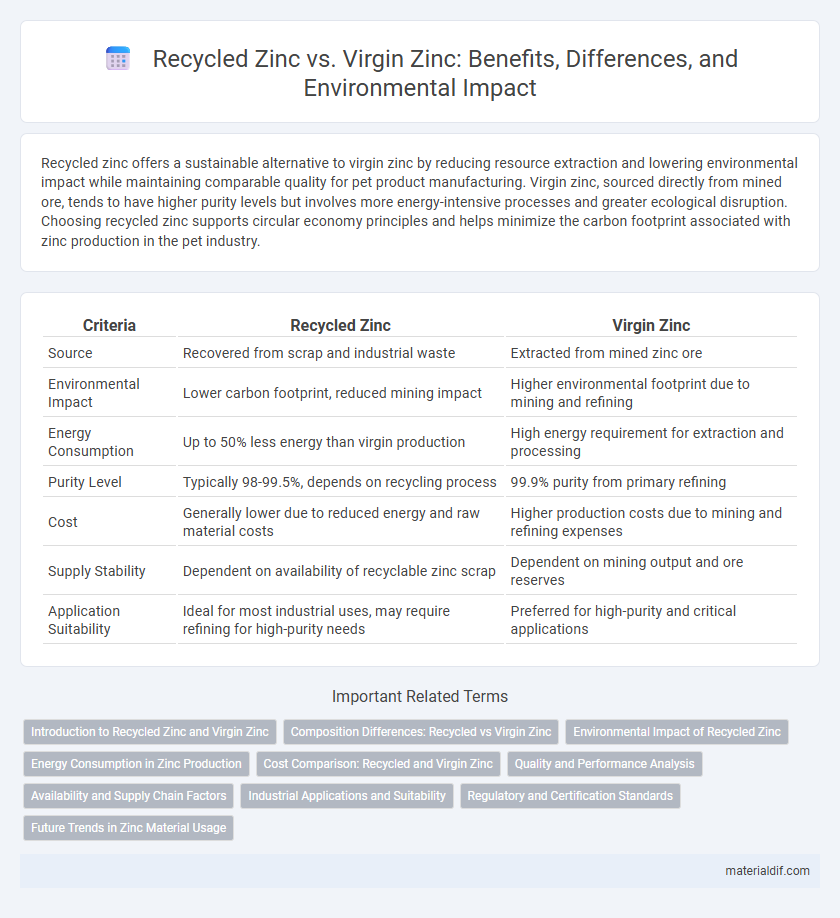

| Criteria | Recycled Zinc | Virgin Zinc |

|---|---|---|

| Source | Recovered from scrap and industrial waste | Extracted from mined zinc ore |

| Environmental Impact | Lower carbon footprint, reduced mining impact | Higher environmental footprint due to mining and refining |

| Energy Consumption | Up to 50% less energy than virgin production | High energy requirement for extraction and processing |

| Purity Level | Typically 98-99.5%, depends on recycling process | 99.9% purity from primary refining |

| Cost | Generally lower due to reduced energy and raw material costs | Higher production costs due to mining and refining expenses |

| Supply Stability | Dependent on availability of recyclable zinc scrap | Dependent on mining output and ore reserves |

| Application Suitability | Ideal for most industrial uses, may require refining for high-purity needs | Preferred for high-purity and critical applications |

Introduction to Recycled Zinc and Virgin Zinc

Recycled zinc is sourced from recovered zinc materials such as scrap metal, dust, and industrial by-products, reducing environmental impact and conserving natural resources compared to virgin zinc, which is extracted directly from zinc ores through mining and refining processes. Virgin zinc typically offers higher purity levels but requires significant energy consumption and greenhouse gas emissions during extraction. Using recycled zinc supports sustainable manufacturing and circular economy principles by minimizing waste and lowering the carbon footprint of zinc production.

Composition Differences: Recycled vs Virgin Zinc

Recycled zinc typically contains trace impurities from previous applications, resulting in slight variations in alloy composition compared to virgin zinc, which is extracted directly from ores and features a higher purity level. The presence of contaminants in recycled zinc can affect its mechanical properties and corrosion resistance, necessitating refining processes to meet specific industry standards. Virgin zinc's consistent elemental makeup provides predictable performance in applications such as galvanizing and die casting, whereas recycled zinc contributes to sustainability efforts by reducing the environmental impact associated with mining.

Environmental Impact of Recycled Zinc

Recycled zinc significantly reduces environmental impact by lowering energy consumption by up to 50% compared to virgin zinc production and decreasing greenhouse gas emissions. Utilizing recycled zinc conserves natural resources, reduces mining waste, and limits habitat destruction. The closed-loop recycling process minimizes pollution and supports sustainable metal management in industrial applications.

Energy Consumption in Zinc Production

Recycled zinc uses up to 50-60% less energy compared to virgin zinc production, significantly reducing overall carbon emissions. The energy-intensive extraction and refining processes in virgin zinc demand high electricity and fuel consumption, whereas recycling leverages existing material, cutting energy needs drastically. This energy efficiency makes recycled zinc a more sustainable choice in zinc manufacturing and industrial applications.

Cost Comparison: Recycled and Virgin Zinc

Recycled zinc generally costs 20-40% less than virgin zinc due to lower energy consumption and reduced raw material extraction expenses. Virgin zinc production involves extensive mining and refining processes, contributing to higher prices fluctuating with ore availability and geopolitical factors. Utilizing recycled zinc not only reduces environmental impact but also offers significant cost savings for manufacturers and end-users.

Quality and Performance Analysis

Recycled zinc maintains comparable quality to virgin zinc, exhibiting consistent purity levels typically above 98%, which ensures reliable performance in galvanization and alloy production. The mechanical properties of recycled zinc, including tensile strength and corrosion resistance, closely match those of virgin zinc, making it suitable for industrial applications without compromising durability. Advanced recycling processes minimize impurities, preserving zinc's chemical integrity and enabling sustainable resource utilization without sacrificing performance standards.

Availability and Supply Chain Factors

Recycled zinc significantly enhances availability by reducing dependence on mining and mitigating raw material scarcity, ensuring a more stable supply chain amidst fluctuating global demand. Virgin zinc extraction faces challenges such as environmental regulations and resource depletion, which can disrupt production and elevate costs. The integration of recycled zinc into the supply chain improves sustainability, lowers energy consumption, and supports circular economy initiatives.

Industrial Applications and Suitability

Recycled zinc offers comparable corrosion resistance and mechanical properties to virgin zinc, making it highly suitable for industrial applications such as galvanizing steel, die-casting, and battery production. Utilizing recycled zinc reduces energy consumption by up to 60% compared to virgin zinc extraction, enhancing sustainability in manufacturing processes. Industrial sectors prioritize recycled zinc for cost-efficiency and environmental compliance without compromising product quality and durability.

Regulatory and Certification Standards

Recycled zinc meets stringent regulatory and certification standards such as those outlined by the European REACH regulations and the U.S. EPA, ensuring minimal environmental impact and compliance with safety requirements. Virgin zinc production adheres to ISO 9001 and ISO 14001 standards, focusing on quality management and environmental practices, but often involves higher carbon emissions compared to recycled zinc. Certification programs like the Responsible Minerals Initiative (RMI) promote transparency and responsible sourcing for both recycled and virgin zinc materials in global supply chains.

Future Trends in Zinc Material Usage

Recycled zinc offers significant environmental benefits by reducing energy consumption and greenhouse gas emissions compared to virgin zinc extraction. Future trends in zinc material usage emphasize increased recycling rates driven by circular economy initiatives and stricter environmental regulations. Innovations in zinc recovery technologies are expected to enhance the quality and efficiency of recycled zinc, making it more competitive with virgin zinc in various industrial applications.

Recycled Zinc vs Virgin Zinc Infographic

materialdif.com

materialdif.com