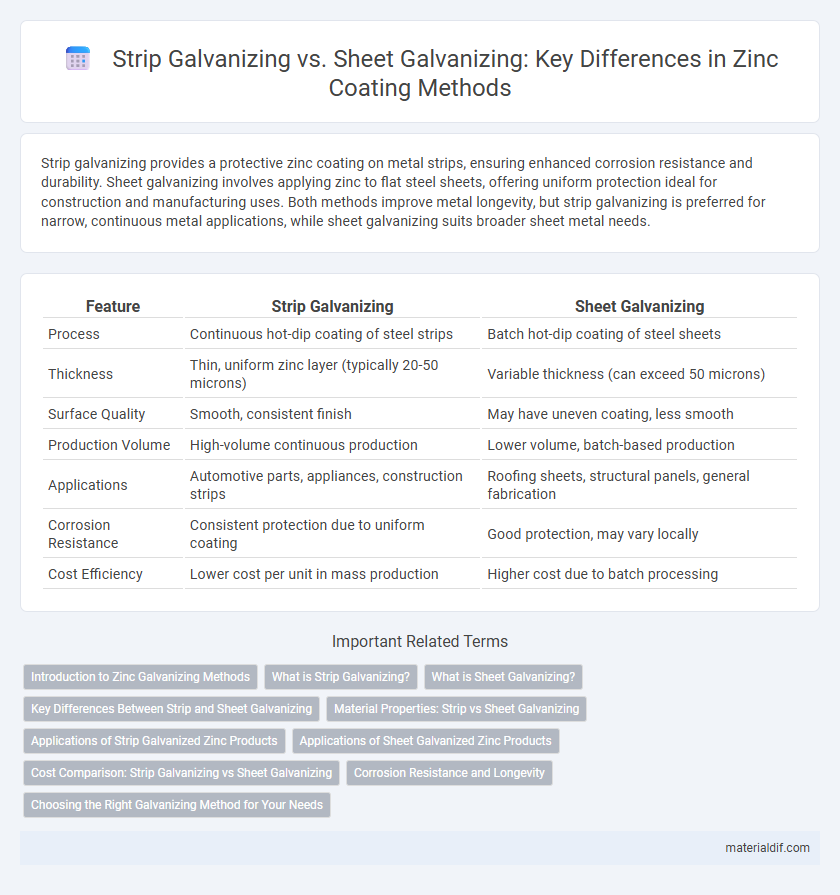

Strip galvanizing provides a protective zinc coating on metal strips, ensuring enhanced corrosion resistance and durability. Sheet galvanizing involves applying zinc to flat steel sheets, offering uniform protection ideal for construction and manufacturing uses. Both methods improve metal longevity, but strip galvanizing is preferred for narrow, continuous metal applications, while sheet galvanizing suits broader sheet metal needs.

Table of Comparison

| Feature | Strip Galvanizing | Sheet Galvanizing |

|---|---|---|

| Process | Continuous hot-dip coating of steel strips | Batch hot-dip coating of steel sheets |

| Thickness | Thin, uniform zinc layer (typically 20-50 microns) | Variable thickness (can exceed 50 microns) |

| Surface Quality | Smooth, consistent finish | May have uneven coating, less smooth |

| Production Volume | High-volume continuous production | Lower volume, batch-based production |

| Applications | Automotive parts, appliances, construction strips | Roofing sheets, structural panels, general fabrication |

| Corrosion Resistance | Consistent protection due to uniform coating | Good protection, may vary locally |

| Cost Efficiency | Lower cost per unit in mass production | Higher cost due to batch processing |

Introduction to Zinc Galvanizing Methods

Zinc galvanizing methods, including strip galvanizing and sheet galvanizing, offer essential corrosion protection by applying a zinc coating to steel substrates. Strip galvanizing typically involves continuous hot-dip immersion of steel coils, providing uniform zinc layers ideal for manufacturing durable components. Sheet galvanizing, often applied to flat steel sheets, involves controlled zinc deposition ensuring enhanced surface resistance and longevity in automotive and construction industries.

What is Strip Galvanizing?

Strip galvanizing is a process where steel strips are continuously fed through a molten zinc bath to form a uniform zinc coating that enhances corrosion resistance. This method ensures a consistent protective layer on steel used in automotive parts, construction materials, and appliances, promoting durability. Compared to sheet galvanizing, strip galvanizing offers higher efficiency for large-scale production without compromising the zinc layer's adhesion and thickness.

What is Sheet Galvanizing?

Sheet galvanizing involves coating thin steel sheets with a layer of zinc through a continuous hot-dip process, enhancing corrosion resistance and surface durability. This technique ensures uniform zinc coverage, making galvanized sheets ideal for automotive panels, roofing, and appliances where consistent thickness and finish are crucial. Compared to strip galvanizing, sheet galvanizing emphasizes finished product quality and precise zinc coating control for industrial applications.

Key Differences Between Strip and Sheet Galvanizing

Strip galvanizing involves coating narrow, continuous metal strips with zinc, offering enhanced corrosion resistance primarily for components like fasteners and automotive parts. Sheet galvanizing applies zinc to broader flat steel sheets, commonly used in construction and appliance manufacturing due to its uniform protection over large surface areas. Key differences lie in their application methods, product dimensions, and typical industrial uses, with strip galvanizing optimizing flexibility and sheet galvanizing maximizing surface coverage.

Material Properties: Strip vs Sheet Galvanizing

Strip galvanizing involves coating thin steel strips with zinc, resulting in enhanced flexibility and better surface uniformity compared to thicker sheets. Sheet galvanizing offers superior corrosion resistance due to its increased thickness, making it ideal for structural applications requiring durability. The material properties differ primarily in mechanical strength and zinc layer adhesion, where strip galvanizing provides improved formability while sheet galvanizing excels in long-term protection.

Applications of Strip Galvanized Zinc Products

Strip galvanized zinc products are widely used in automotive manufacturing for corrosion-resistant body panels and structural components, enhancing durability in harsh environments. They serve critical roles in electrical appliances, providing protective coatings that prevent rust and extend product lifespan. Additionally, strip galvanizing is essential in construction for metal roofing, cladding, and framing materials due to its superior adhesion and flexibility compared to sheet galvanizing.

Applications of Sheet Galvanized Zinc Products

Sheet galvanizing of zinc products is widely utilized in automotive body panels, roofing sheets, and HVAC ductwork due to its superior corrosion resistance and uniform coating thickness. This process enhances the durability of steel sheets used in construction, electrical appliances, and agricultural equipment, ensuring long-term protection against rust. The consistent zinc coating on sheet galvanized products also facilitates better paint adhesion, making them ideal for both practical and aesthetic applications.

Cost Comparison: Strip Galvanizing vs Sheet Galvanizing

Strip galvanizing typically incurs lower costs compared to sheet galvanizing due to its thinner zinc coating and faster production processes, which reduces material and labor expenses. Sheet galvanizing involves thicker zinc layers for enhanced corrosion resistance, leading to higher zinc consumption and increased processing time, elevating overall costs. Evaluating project requirements for durability versus budget constraints helps determine the most cost-effective galvanizing method.

Corrosion Resistance and Longevity

Strip galvanizing provides superior corrosion resistance due to its thicker and more uniform zinc coating, which enhances protection against rust and environmental damage compared to sheet galvanizing. Sheet galvanizing, typically applied to thinner gauge steel, offers adequate corrosion protection but tends to have a shorter lifespan in harsh conditions. The increased longevity of strip galvanizing makes it ideal for applications requiring durable, long-term resistance to corrosion.

Choosing the Right Galvanizing Method for Your Needs

Strip galvanizing involves continuous coating of steel strips with zinc, offering uniform protection and ideal for high-volume production, while sheet galvanizing applies zinc to pre-cut steel sheets, allowing customization for specific sizes and shapes. Selecting the right method depends on project requirements such as volume, precision, and application environment, with strip galvanizing favored for automotive and construction industries and sheet galvanizing preferred in fabrication and roofing. Assessing factors like corrosion resistance, cost-efficiency, and material dimensions ensures optimal performance and longevity of the galvanized products.

Strip Galvanizing vs Sheet Galvanizing Infographic

materialdif.com

materialdif.com