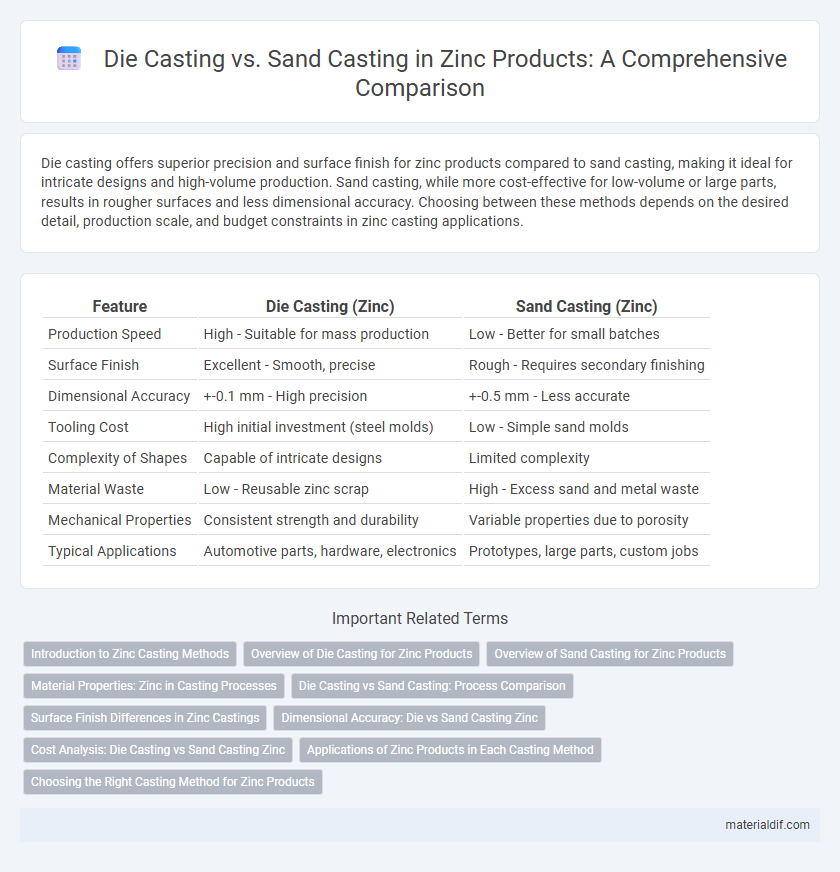

Die casting offers superior precision and surface finish for zinc products compared to sand casting, making it ideal for intricate designs and high-volume production. Sand casting, while more cost-effective for low-volume or large parts, results in rougher surfaces and less dimensional accuracy. Choosing between these methods depends on the desired detail, production scale, and budget constraints in zinc casting applications.

Table of Comparison

| Feature | Die Casting (Zinc) | Sand Casting (Zinc) |

|---|---|---|

| Production Speed | High - Suitable for mass production | Low - Better for small batches |

| Surface Finish | Excellent - Smooth, precise | Rough - Requires secondary finishing |

| Dimensional Accuracy | +-0.1 mm - High precision | +-0.5 mm - Less accurate |

| Tooling Cost | High initial investment (steel molds) | Low - Simple sand molds |

| Complexity of Shapes | Capable of intricate designs | Limited complexity |

| Material Waste | Low - Reusable zinc scrap | High - Excess sand and metal waste |

| Mechanical Properties | Consistent strength and durability | Variable properties due to porosity |

| Typical Applications | Automotive parts, hardware, electronics | Prototypes, large parts, custom jobs |

Introduction to Zinc Casting Methods

Zinc casting methods primarily include die casting and sand casting, each offering unique advantages for manufacturing. Die casting produces high-precision, complex zinc components through high-pressure injection, ensuring superior surface finish and dimensional accuracy. Sand casting, by contrast, is more versatile and cost-effective for low-volume or large zinc parts but results in rougher surfaces and lower consistency.

Overview of Die Casting for Zinc Products

Die casting for zinc products involves injecting molten zinc alloy into a steel mold under high pressure, resulting in high-precision, complex shapes with excellent surface finish and dimensional consistency. This process enables rapid production cycles and superior mechanical properties compared to other casting methods like sand casting. High thermal conductivity and low melting point of zinc alloys make die casting especially efficient and cost-effective for mass manufacturing of intricate components.

Overview of Sand Casting for Zinc Products

Sand casting for zinc products involves creating molds from compacted sand that shapes molten zinc into complex designs with high dimensional accuracy. This method is cost-effective for small production runs and allows for large casting sizes, though it typically results in a rougher surface finish compared to die casting. Zinc's low melting point and excellent fluidity make it ideal for sand casting, enabling detailed features and robust mechanical properties in the final product.

Material Properties: Zinc in Casting Processes

Zinc's low melting point (around 420degC) and excellent fluidity make it highly suitable for die casting, producing precise, thin-walled parts with superior surface finish and dimensional accuracy. Sand casting, while more versatile for larger, complex shapes, often results in coarser grain structures and lower mechanical strength due to slower cooling rates in zinc alloys. The inherent material properties of zinc favor die casting for high-volume, intricate components demanding enhanced durability and tight tolerances.

Die Casting vs Sand Casting: Process Comparison

Die casting zinc involves injecting molten metal under high pressure into reusable steel molds, resulting in high precision, smooth surface finishes, and consistent dimensional accuracy suitable for mass production. Sand casting zinc uses sand molds to form parts, offering greater flexibility for complex shapes and lower tooling costs but with rougher surfaces and less dimensional control. Die casting is optimal for high-volume, detailed zinc components, while sand casting suits low-volume, larger, or intricate designs requiring cost-effective tooling.

Surface Finish Differences in Zinc Castings

Die casting of zinc offers a superior surface finish with smooth, detailed textures and minimal post-processing, making it ideal for precision components and aesthetic applications. In contrast, sand casting produces rougher surfaces due to the granular mold material, often requiring additional machining or finishing to meet quality standards. The enhanced surface quality of die-cast zinc parts reduces defects and improves paint adhesion, which is critical in automotive and consumer electronics industries.

Dimensional Accuracy: Die vs Sand Casting Zinc

Die casting zinc products offers superior dimensional accuracy with tolerances typically around +-0.1 mm, enabling intricate and precise designs. In contrast, sand casting zinc results in lower dimensional accuracy, with typical tolerances of +-0.5 mm or more due to mold deformation and shrinkage. The high precision of die casting reduces post-processing costs and enhances surface finish quality in zinc components.

Cost Analysis: Die Casting vs Sand Casting Zinc

Die casting zinc products generally incur higher initial tooling costs but offer lower per-unit expenses due to faster production cycles and reduced labor requirements. Sand casting zinc has lower upfront costs, making it suitable for small batch production, but involves longer cycle times and increased manual labor, resulting in higher per-piece costs as volume rises. For large-scale zinc manufacturing, die casting proves more cost-effective, while sand casting remains economically viable for limited runs or custom shapes.

Applications of Zinc Products in Each Casting Method

Die casting of zinc is widely used in producing complex, high-precision components such as automotive parts, electronics housings, and hardware fittings due to its excellent surface finish and dimensional accuracy. Sand casting of zinc is preferred for larger, less intricate parts like architectural elements, valve bodies, and machinery bases where flexibility in size and design modifications is essential. Each casting method leverages zinc's corrosion resistance and strength, optimizing performance based on application-specific requirements.

Choosing the Right Casting Method for Zinc Products

Choosing the right casting method for zinc products depends on the desired precision and production volume, with die casting offering high accuracy and smooth surface finishes ideal for complex and high-volume components. Sand casting provides greater design flexibility and lower tooling costs, making it suitable for larger, less detailed zinc parts or smaller production runs. Evaluating factors such as dimensional tolerances, surface quality, and cost-efficiency is crucial to optimize zinc casting outcomes.

Die Casting vs Sand Casting (in Zinc products) Infographic

materialdif.com

materialdif.com