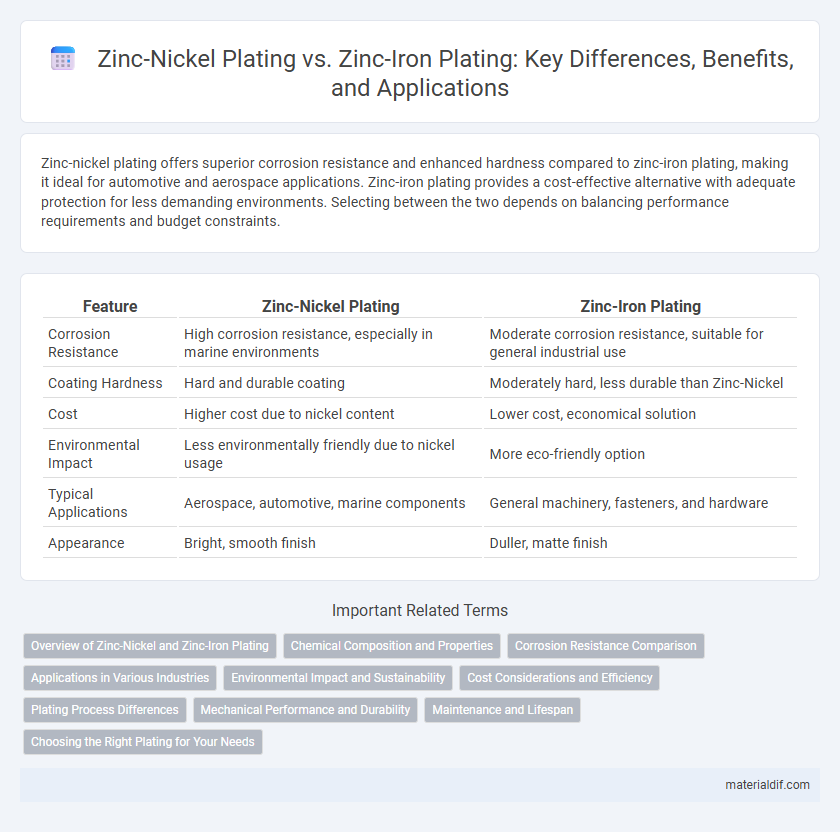

Zinc-nickel plating offers superior corrosion resistance and enhanced hardness compared to zinc-iron plating, making it ideal for automotive and aerospace applications. Zinc-iron plating provides a cost-effective alternative with adequate protection for less demanding environments. Selecting between the two depends on balancing performance requirements and budget constraints.

Table of Comparison

| Feature | Zinc-Nickel Plating | Zinc-Iron Plating |

|---|---|---|

| Corrosion Resistance | High corrosion resistance, especially in marine environments | Moderate corrosion resistance, suitable for general industrial use |

| Coating Hardness | Hard and durable coating | Moderately hard, less durable than Zinc-Nickel |

| Cost | Higher cost due to nickel content | Lower cost, economical solution |

| Environmental Impact | Less environmentally friendly due to nickel usage | More eco-friendly option |

| Typical Applications | Aerospace, automotive, marine components | General machinery, fasteners, and hardware |

| Appearance | Bright, smooth finish | Duller, matte finish |

Overview of Zinc-Nickel and Zinc-Iron Plating

Zinc-nickel plating offers superior corrosion resistance and higher hardness compared to zinc-iron plating, making it ideal for automotive and aerospace applications requiring enhanced durability. Zinc-iron plating provides a cost-effective solution with good adhesion and moderate corrosion protection, commonly used in general industrial and hardware components. Both coatings deposit a zinc alloy layer on steel substrates, but zinc-nickel typically contains 12-15% nickel for optimal performance, whereas zinc-iron includes approximately 8-10% iron.

Chemical Composition and Properties

Zinc-Nickel plating typically consists of 12-15% nickel combined with zinc, offering enhanced corrosion resistance and superior hardness compared to standard zinc coatings. Zinc-Iron plating features a zinc matrix with iron inclusion, providing good adhesion and increased wear resistance but generally lower corrosion protection than Zinc-Nickel alloys. The chemical composition of Zinc-Nickel plating results in a more uniform and compact layer, making it ideal for automotive and aerospace applications requiring durability and corrosion resistance.

Corrosion Resistance Comparison

Zinc-nickel plating exhibits superior corrosion resistance compared to zinc-iron plating due to the uniform alloy layer and higher nickel content, which enhances passivation and durability in harsh environments. This plating method effectively protects steel surfaces from rust in automotive and aerospace applications, withstanding salt spray tests exceeding 1,000 hours. Zinc-iron plating, while cost-effective, typically offers lower corrosion protection, making it suitable for less demanding industrial uses.

Applications in Various Industries

Zinc-nickel plating provides superior corrosion resistance and is widely used in automotive and aerospace industries for critical components such as fasteners and structural parts. Zinc-iron plating offers excellent wear resistance and is commonly applied in electronics and machinery manufacturing, where durability under mechanical stress is essential. Both platings enhance surface protection but serve different industrial needs based on environmental exposure and performance requirements.

Environmental Impact and Sustainability

Zinc-nickel plating offers superior corrosion resistance and longer lifespan, reducing the frequency of recoating and minimizing environmental waste compared to zinc-iron plating. Zinc-iron plating typically involves higher energy consumption and generates more hazardous byproducts during the plating process, impacting sustainability negatively. Choosing zinc-nickel plating supports eco-friendly manufacturing by lowering toxic emissions and promoting resource efficiency in metal finishing industries.

Cost Considerations and Efficiency

Zinc-Nickel plating offers superior corrosion resistance and better performance in aerospace and automotive industries, but it generally comes with higher material and processing costs compared to Zinc-Iron plating. Zinc-Iron plating is more cost-effective for large-scale applications due to its lower nickel content and simpler processing, making it efficient for budget-sensitive projects requiring moderate corrosion protection. Both methods require careful evaluation of cost-benefit ratios, considering factors such as environmental regulations, application lifespan, and maintenance expenses.

Plating Process Differences

Zinc-nickel plating involves an electrochemical process where a nickel alloy is co-deposited with zinc, offering superior corrosion resistance and higher hardness compared to zinc-iron plating. Zinc-iron plating uses a similar electrolytic bath but deposits a zinc-iron alloy that provides good adhesion and moderate corrosion protection, typically at lower costs. The plating parameters, including bath composition, temperature, and current density, differ significantly to achieve specific alloy ratios and performance characteristics in each process.

Mechanical Performance and Durability

Zinc-nickel plating offers superior mechanical performance with enhanced hardness and better resistance to wear compared to zinc-iron plating, making it ideal for high-stress applications. Zinc-nickel alloys provide greater corrosion resistance and durability, maintaining protective properties even under harsh environmental conditions. In contrast, zinc-iron plating tends to be less resilient against mechanical deformation and long-term exposure to corrosive elements.

Maintenance and Lifespan

Zinc-nickel plating offers superior corrosion resistance and longer lifespan compared to zinc-iron plating, often exceeding 1,000 hours salt spray testing versus 500-700 hours for zinc-iron. Maintenance requirements for zinc-nickel are lower due to its enhanced durability and uniform coating, reducing the need for frequent reapplication or touch-ups. Zinc-iron plating, while more cost-effective, requires more regular inspection and maintenance to prevent surface degradation and ensure effective protection.

Choosing the Right Plating for Your Needs

Zinc-nickel plating offers superior corrosion resistance and is ideal for automotive and aerospace applications requiring high durability against harsh environments. Zinc-iron plating provides excellent corrosion protection with a more cost-effective solution, suitable for general industrial use where budget constraints are a priority. Selecting the right plating depends on factors such as corrosion resistance requirements, application environment, and cost considerations to ensure optimal performance and longevity.

Zinc-Nickel Plating vs Zinc-Iron Plating Infographic

materialdif.com

materialdif.com