Die-cast zinc offers superior strength and durability compared to spun zinc, making it ideal for heavy-duty applications and intricate designs. Spun zinc is lighter and more flexible, suitable for decorative elements and applications where weight is a concern. Choosing between die-cast and spun zinc depends on the required balance between rigidity, detail, and weight for the specific project.

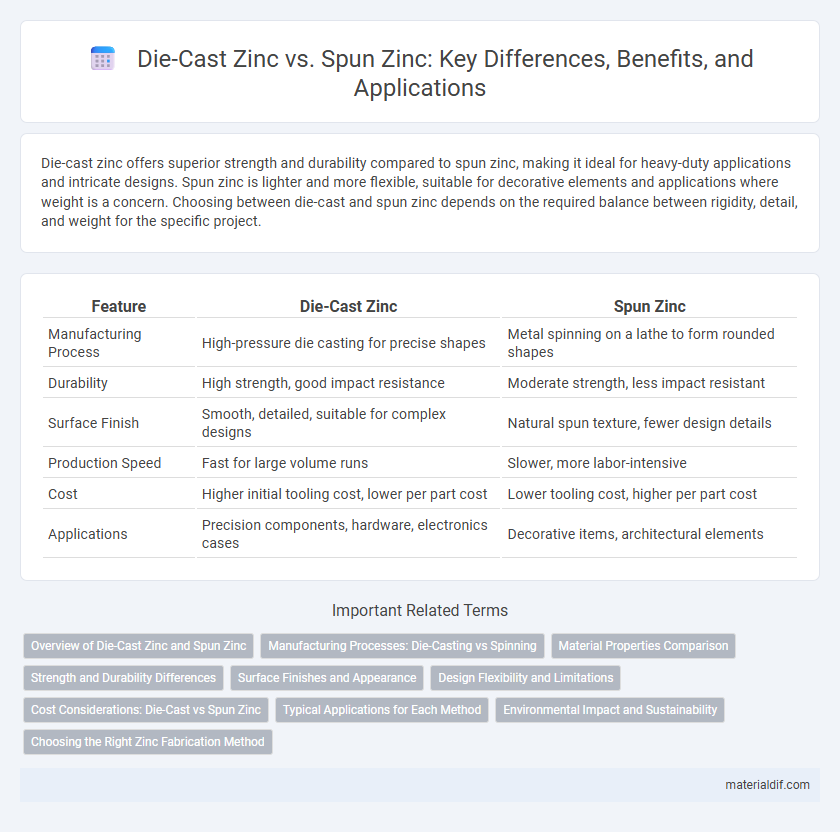

Table of Comparison

| Feature | Die-Cast Zinc | Spun Zinc |

|---|---|---|

| Manufacturing Process | High-pressure die casting for precise shapes | Metal spinning on a lathe to form rounded shapes |

| Durability | High strength, good impact resistance | Moderate strength, less impact resistant |

| Surface Finish | Smooth, detailed, suitable for complex designs | Natural spun texture, fewer design details |

| Production Speed | Fast for large volume runs | Slower, more labor-intensive |

| Cost | Higher initial tooling cost, lower per part cost | Lower tooling cost, higher per part cost |

| Applications | Precision components, hardware, electronics cases | Decorative items, architectural elements |

Overview of Die-Cast Zinc and Spun Zinc

Die-cast zinc is produced by injecting molten zinc into steel molds under high pressure, resulting in precise, durable components with excellent dimensional stability and complex shapes. Spun zinc is created by rotating a zinc sheet at high speeds while shaping it into a form, offering lightweight, corrosion-resistant parts often used in decorative and architectural applications. Die-cast zinc provides higher strength and intricate detailing, whereas spun zinc emphasizes flexibility and surface finish quality.

Manufacturing Processes: Die-Casting vs Spinning

Die-cast zinc involves injecting molten zinc into a metal mold under high pressure, producing precise, complex shapes with excellent surface finishes and dimensional accuracy. Spun zinc is formed by rotating a flat zinc sheet on a lathe while shaping it with tools, ideal for symmetrical, hollow components but with less detail and surface accuracy compared to die-casting. Die-casting offers faster production for intricate parts, whereas spinning provides flexibility for custom, low-volume runs.

Material Properties Comparison

Die-cast zinc features higher density and superior dimensional accuracy compared to spun zinc, resulting in enhanced strength and durability ideal for precision components. Spun zinc offers greater malleability and better surface finish, making it suitable for decorative applications with complex shapes. Corrosion resistance is robust in both, but die-cast zinc typically exhibits improved mechanical properties due to its controlled casting process.

Strength and Durability Differences

Die-cast zinc offers superior strength and durability compared to spun zinc due to its dense, uniform metal composition achieved through high-pressure mold casting. This process results in higher tensile strength and better resistance to wear, impacts, and corrosion, making die-cast zinc ideal for heavy-duty applications. In contrast, spun zinc, formed by shaping a zinc sheet, has less structural integrity and is more prone to deformation under stress, limiting its use to decorative or light-duty purposes.

Surface Finishes and Appearance

Die-cast zinc offers a smooth, uniform surface finish with precise detailing, making it ideal for intricate designs and high-quality appearance requirements. Spun zinc features a more textured and matte finish, providing a traditional aesthetic often preferred for architectural and decorative applications. Both materials resist corrosion well, but die-cast zinc allows for more consistent paint adhesion and finer surface treatments.

Design Flexibility and Limitations

Die-cast zinc offers superior design flexibility with complex shapes, intricate details, and tight tolerances due to its ability to fill molds under high pressure, making it ideal for precision components. Spun zinc, formed by shaping flat sheet metal through spinning, is limited to simpler, symmetrical designs and cannot achieve the same level of detail or dimensional accuracy. The choice between die-cast and spun zinc depends on the complexity of the design and the required aesthetic or functional features.

Cost Considerations: Die-Cast vs Spun Zinc

Die-cast zinc offers greater cost efficiency for high-volume production due to faster cycle times and less manual labor compared to spun zinc. Spun zinc incurs higher labor costs and material waste because it relies on skilled craftsmanship and slower manufacturing processes. The upfront investment in die casting molds is offset by reduced per-unit costs over larger production runs, making die-cast zinc preferable for cost-conscious projects.

Typical Applications for Each Method

Die-cast zinc is typically used in manufacturing precision components such as automotive parts, hardware fittings, and electronic housings due to its high strength and excellent dimensional accuracy. Spun zinc is commonly applied in decorative architectural elements, water fountains, and custom lighting fixtures because it allows for smooth, seamless curved shapes and a polished finish. Each method caters to specific industry needs based on the balance between structural integrity and aesthetic appeal.

Environmental Impact and Sustainability

Die-cast zinc demonstrates higher environmental impact due to energy-intensive manufacturing processes and increased CO2 emissions compared to spun zinc, which utilizes less energy and produces fewer pollutants. Spun zinc's sustainability benefits include higher recyclability and a longer lifecycle, reducing material waste and conserving resources. Choosing spun zinc over die-cast zinc supports reduced carbon footprint and promotes eco-friendly metal production practices.

Choosing the Right Zinc Fabrication Method

Die-cast zinc offers superior strength, precision, and intricate detail, making it ideal for complex components and high-volume production runs. Spun zinc, formed through metal spinning, provides excellent corrosion resistance and a smooth finish, typically used for decorative applications and lower-volume fabrication. Selecting the appropriate zinc fabrication method depends on factors such as design complexity, production scale, and required durability for the intended use.

Die-cast zinc vs spun zinc Infographic

materialdif.com

materialdif.com