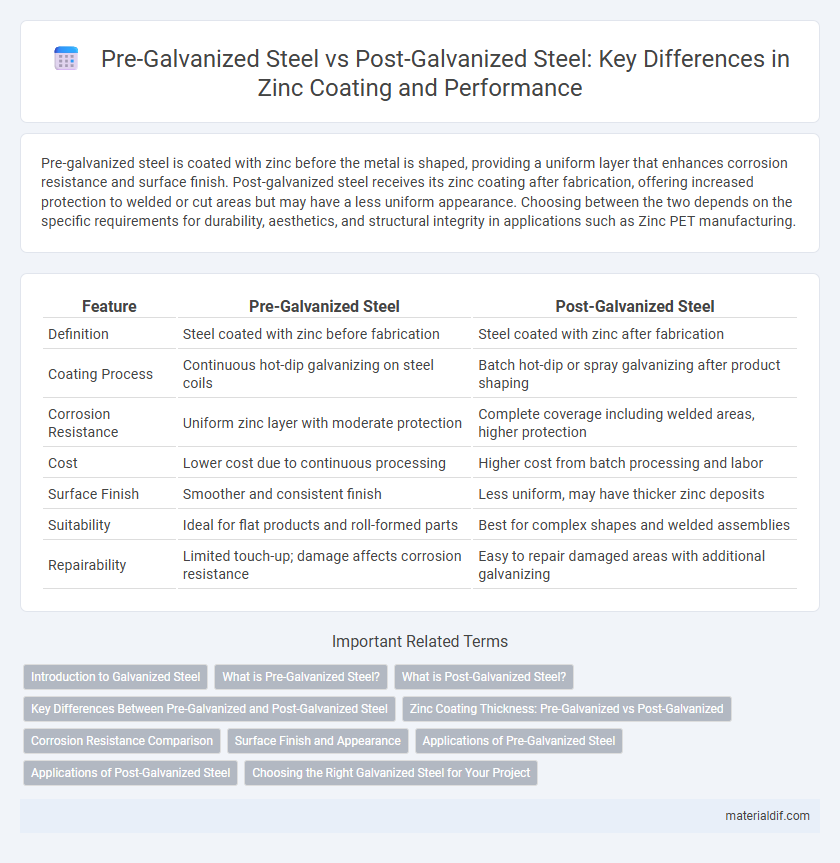

Pre-galvanized steel is coated with zinc before the metal is shaped, providing a uniform layer that enhances corrosion resistance and surface finish. Post-galvanized steel receives its zinc coating after fabrication, offering increased protection to welded or cut areas but may have a less uniform appearance. Choosing between the two depends on the specific requirements for durability, aesthetics, and structural integrity in applications such as Zinc PET manufacturing.

Table of Comparison

| Feature | Pre-Galvanized Steel | Post-Galvanized Steel |

|---|---|---|

| Definition | Steel coated with zinc before fabrication | Steel coated with zinc after fabrication |

| Coating Process | Continuous hot-dip galvanizing on steel coils | Batch hot-dip or spray galvanizing after product shaping |

| Corrosion Resistance | Uniform zinc layer with moderate protection | Complete coverage including welded areas, higher protection |

| Cost | Lower cost due to continuous processing | Higher cost from batch processing and labor |

| Surface Finish | Smoother and consistent finish | Less uniform, may have thicker zinc deposits |

| Suitability | Ideal for flat products and roll-formed parts | Best for complex shapes and welded assemblies |

| Repairability | Limited touch-up; damage affects corrosion resistance | Easy to repair damaged areas with additional galvanizing |

Introduction to Galvanized Steel

Galvanized steel is steel coated with a layer of zinc to protect it from corrosion and extend its lifespan. Pre-galvanized steel is coated before fabrication, ensuring uniform corrosion resistance but limited to flat or simple shapes, while post-galvanized steel is coated after fabrication, allowing complete coverage even on complex structures. Zinc acts as a sacrificial anode, preventing rust and enhancing durability in various industrial and construction applications.

What is Pre-Galvanized Steel?

Pre-galvanized steel is a type of carbon steel sheet that has been coated with zinc before fabrication, providing corrosion resistance through a continuous zinc layer applied in a controlled factory environment. This coating process, typically done via hot-dip galvanizing or electro-galvanizing, ensures uniform protection and longevity in various industrial applications. Pre-galvanized steel is often used in construction, automotive, and appliance manufacturing due to its enhanced durability and cost-effectiveness compared to post-galvanized steel.

What is Post-Galvanized Steel?

Post-galvanized steel is steel that has been coated with zinc after the fabrication process, offering enhanced corrosion resistance for finished products. This method allows for selective galvanizing of welded or cut areas, ensuring durable protection where metal exposure occurs. Typically used in construction and automotive industries, post-galvanized steel provides superior long-term durability compared to pre-galvanized steel, especially in environments prone to rust and wear.

Key Differences Between Pre-Galvanized and Post-Galvanized Steel

Pre-galvanized steel undergoes a continuous hot-dip galvanizing process before fabrication, resulting in a uniform zinc coating that enhances corrosion resistance and surface finish. Post-galvanized steel is coated after fabrication, allowing for comprehensive protection of complex shapes and welded areas but may have uneven coverage and require additional labor. Pre-galvanized steel is ideal for cost-effective, high-volume production, whereas post-galvanized steel offers superior protection for custom or intricate steel structures.

Zinc Coating Thickness: Pre-Galvanized vs Post-Galvanized

Pre-galvanized steel typically features a uniform zinc coating ranging from 45 to 70 microns, applied before fabrication, ensuring consistent corrosion resistance during handling and processing. Post-galvanized steel, coated after fabrication via hot-dip galvanizing, achieves thicker zinc layers between 85 and 150 microns, providing enhanced durability in harsh environments. The choice between pre- and post-galvanized steel hinges on zinc coating thickness requirements relative to environmental exposure and structural design.

Corrosion Resistance Comparison

Pre-galvanized steel offers a uniform zinc coating applied before fabrication, providing consistent corrosion resistance during manufacturing but may develop damage at cut edges. Post-galvanized steel undergoes hot-dip galvanizing after fabrication, resulting in a thicker zinc layer that enhances protection, especially on welds and edges vulnerable to corrosion. The overall corrosion resistance of post-galvanized steel surpasses pre-galvanized steel due to its more robust zinc coating and superior coverage on complex steel shapes.

Surface Finish and Appearance

Pre-galvanized steel features a smooth, consistent zinc coating applied before fabrication, producing a uniform surface finish ideal for aesthetic-sensitive applications. Post-galvanized steel undergoes hot-dip galvanization after fabrication, resulting in a thicker, rougher zinc layer with a more textured appearance. The choice between pre- and post-galvanized steel depends on the desired balance between surface smoothness and corrosion resistance.

Applications of Pre-Galvanized Steel

Pre-galvanized steel is widely used in automotive parts, HVAC components, and construction materials due to its uniform zinc coating applied before fabrication, which ensures corrosion resistance and excellent paint adhesion. This steel type is ideal for applications requiring precise dimensional tolerances and minimal post-processing. Its uniform coating makes it highly suitable for manufacturing garages, roofing sheets, and electrical appliances where pre-fabrication protection is critical.

Applications of Post-Galvanized Steel

Post-galvanized steel is prominently used in applications requiring enhanced corrosion resistance and precise coating thickness, such as automotive components, roofing materials, and structural frameworks exposed to harsh environments. Its ability to withstand mechanical stress during fabrication makes it ideal for complex assemblies and welded structures. Industries favor post-galvanized steel for its superior durability in outdoor and industrial settings, ensuring prolonged service life and reduced maintenance costs.

Choosing the Right Galvanized Steel for Your Project

Pre-galvanized steel offers consistent zinc coating controlled in a factory environment, making it ideal for projects requiring uniform corrosion resistance before fabrication. Post-galvanized steel, applied after fabrication, provides superior protection for complex shapes and welds, ensuring enhanced durability where precision coatings are critical. Selecting between pre- and post-galvanized steel depends on project specifics such as fabrication complexity, exposure conditions, and desired longevity.

Pre-Galvanized Steel vs Post-Galvanized Steel Infographic

materialdif.com

materialdif.com