Zinc pet, often found in Zamak, offers superior corrosion resistance and easier casting compared to brass, making it ideal for precise and complex components. Brass, a copper and zinc alloy, excels in durability and aesthetic appeal but is denser and costlier to produce. Choosing between Zamak and brass depends on balancing performance requirements with budget constraints in pet hardware applications.

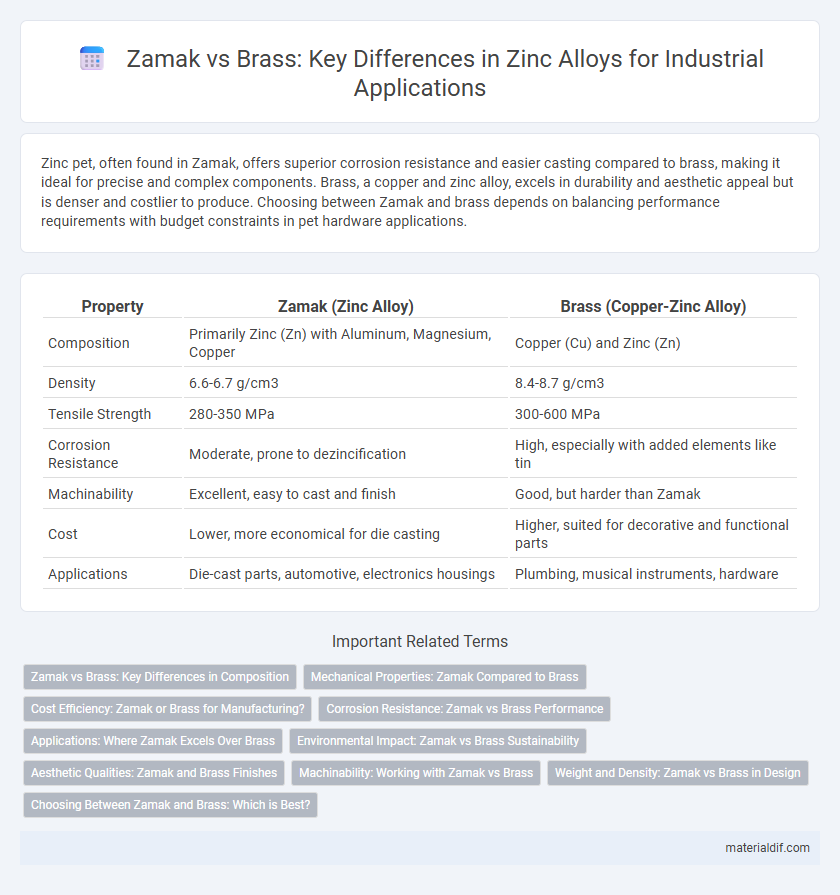

Table of Comparison

| Property | Zamak (Zinc Alloy) | Brass (Copper-Zinc Alloy) |

|---|---|---|

| Composition | Primarily Zinc (Zn) with Aluminum, Magnesium, Copper | Copper (Cu) and Zinc (Zn) |

| Density | 6.6-6.7 g/cm3 | 8.4-8.7 g/cm3 |

| Tensile Strength | 280-350 MPa | 300-600 MPa |

| Corrosion Resistance | Moderate, prone to dezincification | High, especially with added elements like tin |

| Machinability | Excellent, easy to cast and finish | Good, but harder than Zamak |

| Cost | Lower, more economical for die casting | Higher, suited for decorative and functional parts |

| Applications | Die-cast parts, automotive, electronics housings | Plumbing, musical instruments, hardware |

Zamak vs Brass: Key Differences in Composition

Zamak is an alloy primarily composed of zinc with small amounts of aluminum, magnesium, and copper, while brass is mainly made of copper and zinc in varying proportions. The higher zinc content in Zamak enhances its strength and corrosion resistance compared to brass, which tends to be more malleable due to its copper richness. These compositional differences significantly influence their applications, with Zamak favored for die-casting and brass commonly used in decorative and plumbing components.

Mechanical Properties: Zamak Compared to Brass

Zamak alloys typically exhibit higher tensile strength and better hardness compared to brass, making them more suitable for applications requiring enhanced durability and wear resistance. While brass offers superior corrosion resistance and better machinability, Zamak provides more consistent dimensional stability and lower casting shrinkage. These mechanical properties make Zamak ideal for precision die-cast components, whereas brass is often preferred for decorative and electrical applications.

Cost Efficiency: Zamak or Brass for Manufacturing?

Zamak alloys provide a cost-effective solution for manufacturing due to lower raw material expenses and faster casting cycles compared to brass. Brass, while offering superior corrosion resistance and mechanical strength, incurs higher costs because of copper content and more complex machining processes. For high-volume production where budget constraints are critical, zamak typically delivers better cost efficiency without sacrificing essential performance attributes.

Corrosion Resistance: Zamak vs Brass Performance

Zamak alloys typically offer superior corrosion resistance compared to brass, especially in acidic and alkaline environments due to their zinc-dominant composition and protective oxide layer. Brass, an alloy of copper and zinc, can be prone to dezincification corrosion, which undermines its durability in marine or highly corrosive conditions. Zamak's enhanced corrosion resistance makes it a preferred choice for applications requiring long-term exposure to moisture and corrosive elements.

Applications: Where Zamak Excels Over Brass

Zamak alloys excel over brass in applications requiring high precision die casting, such as automotive parts, electronics housings, and hardware components, due to their superior fluidity and dimensional stability. The enhanced corrosion resistance and lower melting point of Zamak make it ideal for producing intricate shapes with tighter tolerances in consumer electronics and household fixtures. Unlike brass, Zamak offers better strength-to-weight ratio, making it preferable for lightweight structural applications where durability and cost-efficiency are critical.

Environmental Impact: Zamak vs Brass Sustainability

Zamak alloys, primarily composed of zinc with small amounts of aluminum, magnesium, and copper, offer better recyclability and a lower environmental footprint compared to brass, which contains significant amounts of copper and zinc. The production of zamak requires less energy and generates fewer greenhouse gas emissions due to the lower melting point of zinc, enhancing its sustainability profile. Brass, while durable, demands more intensive mining and energy use, increasing environmental degradation and carbon emissions.

Aesthetic Qualities: Zamak and Brass Finishes

Zamak offers a smooth, matte finish with consistent color retention and is often used for intricate designs due to its excellent casting properties, enhancing aesthetic appeal in decorative items. Brass provides a warm, golden hue that ages into a desirable patina, offering classic elegance and a rich, timeless look preferred in traditional and vintage designs. The choice between Zamak and Brass finishes depends on desired visual effects, with Zamak favoring modern, sleek aesthetics and Brass delivering a luxurious, antique appearance.

Machinability: Working with Zamak vs Brass

Zamak exhibits superior machinability compared to brass due to its lower melting point and uniform microstructure, allowing for faster cutting speeds and smoother surface finishes. Brass, while harder and more wear-resistant, tends to cause more tool wear and requires slower machining processes to avoid work hardening. In precision manufacturing, zamak is preferred for intricate components where efficient machining and detail retention are critical.

Weight and Density: Zamak vs Brass in Design

Zamak alloys have a density of approximately 6.6 to 7.2 g/cm3, making them significantly lighter than brass, which ranges from 8.4 to 8.7 g/cm3. This weight difference allows designers to choose Zamak for applications requiring reduced mass without compromising structural integrity. The lower density of Zamak enhances ease of handling and cost-effectiveness in manufacturing compared to heavier brass components.

Choosing Between Zamak and Brass: Which is Best?

Zamak, an alloy primarily composed of zinc with aluminum, magnesium, and copper, offers excellent die-casting properties, corrosion resistance, and cost-effectiveness, making it ideal for intricate components and high-volume production. Brass, a copper-zinc alloy, provides superior strength, ductility, and aesthetic appeal, favored in applications requiring durability and decorative finishes. The choice between Zamak and brass hinges on the balance between budget constraints, mechanical requirements, and desired appearance in manufacturing processes.

Zamak vs Brass Infographic

materialdif.com

materialdif.com