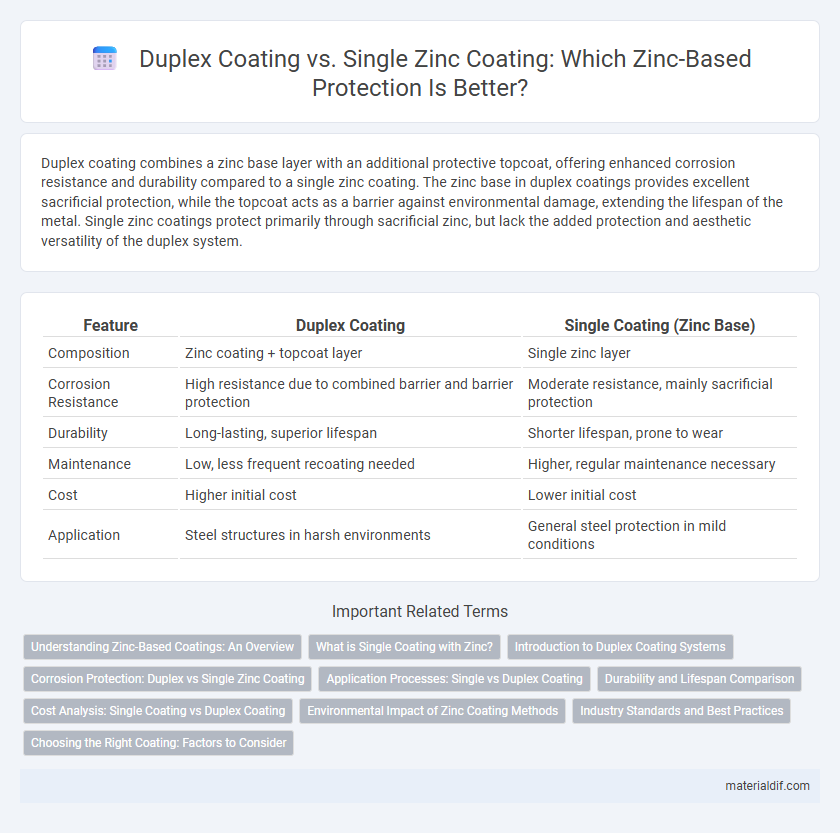

Duplex coating combines a zinc base layer with an additional protective topcoat, offering enhanced corrosion resistance and durability compared to a single zinc coating. The zinc base in duplex coatings provides excellent sacrificial protection, while the topcoat acts as a barrier against environmental damage, extending the lifespan of the metal. Single zinc coatings protect primarily through sacrificial zinc, but lack the added protection and aesthetic versatility of the duplex system.

Table of Comparison

| Feature | Duplex Coating | Single Coating (Zinc Base) |

|---|---|---|

| Composition | Zinc coating + topcoat layer | Single zinc layer |

| Corrosion Resistance | High resistance due to combined barrier and barrier protection | Moderate resistance, mainly sacrificial protection |

| Durability | Long-lasting, superior lifespan | Shorter lifespan, prone to wear |

| Maintenance | Low, less frequent recoating needed | Higher, regular maintenance necessary |

| Cost | Higher initial cost | Lower initial cost |

| Application | Steel structures in harsh environments | General steel protection in mild conditions |

Understanding Zinc-Based Coatings: An Overview

Zinc-based coatings provide corrosion resistance by forming a protective barrier on steel surfaces, commonly applied as single or duplex coatings. Single coatings consist of a zinc layer applied through galvanization, offering sacrificial protection by corroding preferentially to the steel substrate. Duplex coatings combine zinc galvanizing with a layer of paint or powder coating, significantly enhancing durability and extending service life by improving resistance to mechanical damage and environmental factors.

What is Single Coating with Zinc?

Single coating with zinc involves applying a single layer of zinc directly onto a metal surface, providing basic corrosion resistance by creating a protective barrier that prevents rust formation. This zinc layer acts as a sacrificial anode, corroding preferentially to extend the underlying metal's lifespan. Compared to duplex coatings, single zinc coatings offer less durability and corrosion protection, making them suitable for less severe environmental conditions.

Introduction to Duplex Coating Systems

Duplex coating systems combine zinc-based metallic coatings with organic topcoats, enhancing corrosion resistance far beyond single zinc coatings alone. The zinc layer provides sacrificial protection through galvanic action, while the organic layer offers a barrier against moisture and chemicals. This synergistic approach significantly extends the lifespan of steel structures, especially in aggressive environments.

Corrosion Protection: Duplex vs Single Zinc Coating

Duplex coatings, combining a zinc base layer with an organic topcoat, provide superior corrosion protection compared to single zinc coatings by creating a robust barrier against moisture and environmental contaminants. The zinc layer offers sacrificial anodic protection, while the organic topcoat enhances durability and resistance to mechanical damage. This synergy significantly extends the lifespan of steel structures in harsh atmospheric conditions, outperforming single zinc coatings alone.

Application Processes: Single vs Duplex Coating

Single zinc coatings are typically applied through hot-dip galvanizing or electroplating, providing a uniform layer of corrosion protection on metal surfaces. Duplex coating combines a zinc base layer with an organic topcoat, applied sequentially by galvanizing followed by powder or liquid painting, enhancing durability and corrosion resistance. The duplex process offers improved adhesion and extended lifespan by leveraging the synergistic effects of both zinc and organic coatings.

Durability and Lifespan Comparison

Duplex coating combines a zinc base layer with an additional organic topcoat, significantly enhancing corrosion resistance and extending the lifespan beyond that of single zinc coatings alone. Single zinc coatings offer sacrificial protection but typically last 10-15 years in average environments, whereas duplex coatings can extend durability up to 40 years by preventing rust formation even when the coating is scratched. The synergistic effect of zinc's galvanic protection and the organic coating's barrier properties results in superior longevity for steel structures in harsh conditions.

Cost Analysis: Single Coating vs Duplex Coating

Duplex coating, combining a zinc base layer with an organic topcoat, generally incurs higher initial costs compared to single zinc coating due to additional materials and labor. However, the extended corrosion resistance and reduced maintenance frequency often result in lower lifecycle expenses, making duplex systems more cost-effective over time. Single zinc coatings offer lower upfront investment but may require more frequent touch-ups and replacements, increasing long-term maintenance costs.

Environmental Impact of Zinc Coating Methods

Duplex coating combines zinc coating with a top layer of paint, significantly enhancing corrosion resistance and extending the lifespan of steel products while reducing the frequency of recoating and associated environmental waste. Single zinc coating provides sacrificial protection but tends to require more frequent maintenance, leading to increased resource consumption and environmental impact over time. The duplex system's improved durability lowers overall zinc use and energy expenditure, making it a more sustainable option in zinc-based corrosion protection.

Industry Standards and Best Practices

Duplex coating, combining a zinc base layer with a topcoat, significantly enhances corrosion resistance compared to single zinc coatings, aligning with industry standards such as ISO 12944 and NACE guidelines for protective coatings. Best practices recommend duplex systems in aggressive industrial environments to extend maintenance intervals and improve lifespan, often exceeding the performance benchmarks of single zinc coatings outlined in ASTM A123. Implementing duplex coatings ensures compliance with stringent durability criteria while optimizing cost-effectiveness through reduced corrosion-related failures.

Choosing the Right Coating: Factors to Consider

Duplex coating combines zinc with an organic topcoat, offering superior corrosion resistance and extended durability compared to single zinc coatings, which rely solely on zinc's sacrificial protection. When choosing the right coating, factors such as environmental exposure, lifespan requirements, and maintenance costs should be evaluated, with duplex systems excelling in harsh or marine environments. Budget constraints and application conditions can also influence the decision, as single zinc coatings may suffice for indoor or less aggressive settings.

Duplex coating vs Single coating (with zinc base) Infographic

materialdif.com

materialdif.com