Zinc plating offers excellent corrosion resistance for steel by forming a protective barrier and sacrificial layer, making it ideal for outdoor and industrial applications. Chrome plating provides a highly polished, decorative finish along with increased hardness and wear resistance, commonly used in automotive and decorative hardware. Both coatings enhance metal durability, but zinc plating is preferred for corrosion protection while chrome plating prioritizes aesthetics and surface hardness.

Table of Comparison

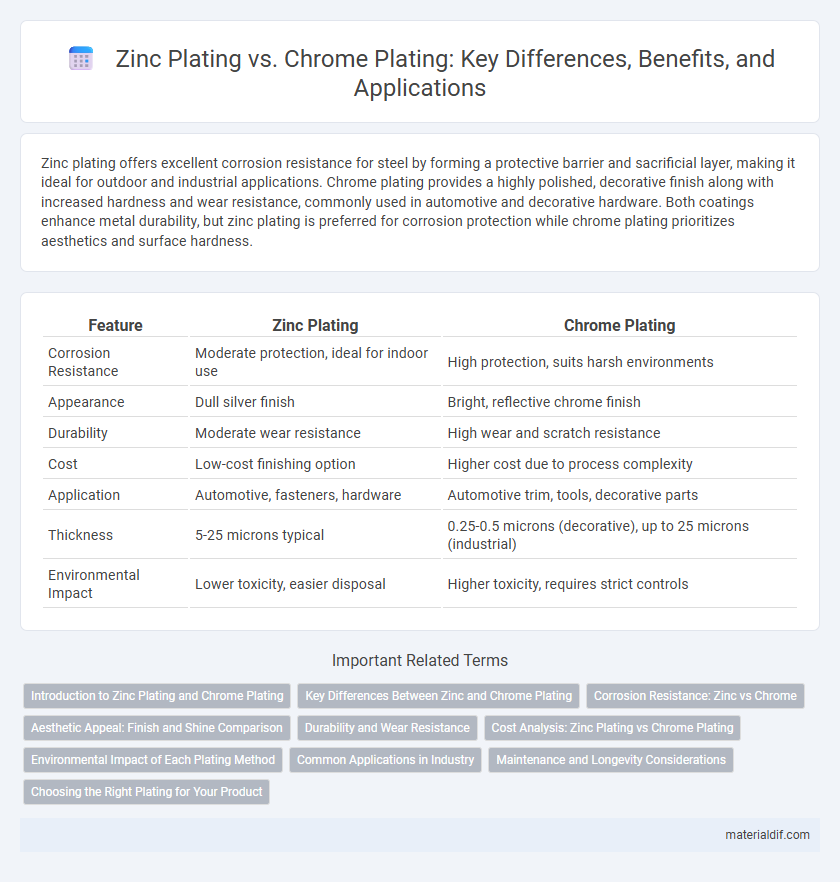

| Feature | Zinc Plating | Chrome Plating |

|---|---|---|

| Corrosion Resistance | Moderate protection, ideal for indoor use | High protection, suits harsh environments |

| Appearance | Dull silver finish | Bright, reflective chrome finish |

| Durability | Moderate wear resistance | High wear and scratch resistance |

| Cost | Low-cost finishing option | Higher cost due to process complexity |

| Application | Automotive, fasteners, hardware | Automotive trim, tools, decorative parts |

| Thickness | 5-25 microns typical | 0.25-0.5 microns (decorative), up to 25 microns (industrial) |

| Environmental Impact | Lower toxicity, easier disposal | Higher toxicity, requires strict controls |

Introduction to Zinc Plating and Chrome Plating

Zinc plating involves applying a thin layer of zinc to metal surfaces to enhance corrosion resistance and improve aesthetic appeal, commonly used in automotive and hardware industries. Chrome plating deposits a layer of chromium, providing superior hardness, corrosion resistance, and a highly reflective finish, often preferred for decorative and industrial applications. Both methods serve distinct purposes, with zinc plating offering cost-effective rust protection, while chrome plating delivers enhanced durability and shine.

Key Differences Between Zinc and Chrome Plating

Zinc plating offers corrosion resistance primarily through sacrificial protection, making it ideal for steel parts exposed to outdoor or humid environments. Chrome plating provides a harder, more wear-resistant surface with a shiny, decorative finish, commonly used in automotive and motorcycle components. Zinc plating is generally more cost-effective but less durable than chrome plating, which excels in aesthetic appeal and extreme surface hardness.

Corrosion Resistance: Zinc vs Chrome

Zinc plating offers excellent corrosion resistance by forming a protective barrier that prevents rust and oxidization, especially effective in outdoor and humid environments. Chrome plating provides a hard, shiny surface with moderate corrosion resistance but is more prone to cracking and corrosion if the layer is damaged. Zinc's sacrificial protection capability outperforms chrome plating, making it a preferred choice for long-term corrosion resistance in industrial applications.

Aesthetic Appeal: Finish and Shine Comparison

Zinc plating offers a bright, matte finish with a subtle metallic sheen that resists corrosion effectively, making it ideal for industrial and utilitarian applications. Chrome plating provides a highly reflective, mirror-like surface with superior shine and smoothness, enhancing aesthetic appeal in automotive and decorative items. While zinc plating emphasizes functional durability, chrome plating prioritizes luxury and visual brilliance in finishing.

Durability and Wear Resistance

Zinc plating offers excellent corrosion resistance and moderate wear resistance, making it ideal for protecting steel components from rust in automotive and construction applications. Chrome plating provides superior hardness and wear resistance, ensuring longer lifespan under abrasive conditions, commonly used in automotive trim and industrial machinery. While zinc plating is cost-effective for anti-corrosion, chrome plating excels in durability for high-friction environments requiring enhanced surface toughness.

Cost Analysis: Zinc Plating vs Chrome Plating

Zinc plating generally offers a more cost-effective solution compared to chrome plating due to lower material and processing expenses. Chrome plating involves higher energy consumption and specialized equipment, resulting in increased labor and operational costs. Industries favor zinc plating for budget-sensitive applications while chrome plating remains preferred for premium finishes despite its higher cost.

Environmental Impact of Each Plating Method

Zinc plating produces fewer hazardous emissions and is less energy-intensive compared to chrome plating, which involves toxic hexavalent chromium compounds harmful to both human health and the environment. Waste from zinc plating is easier to treat and poses less risk of soil and water contamination, while chrome plating requires stringent disposal measures due to its carcinogenic nature. Choosing zinc plating over chrome plating significantly reduces environmental pollution and regulatory compliance challenges in industrial applications.

Common Applications in Industry

Zinc plating is commonly used for automotive parts, fasteners, and hardware due to its excellent corrosion resistance and cost-effectiveness. Chrome plating is favored in the automotive, aerospace, and decorative industries for its high hardness, wear resistance, and aesthetic appeal. Both coatings protect metal surfaces but are selected based on application-specific requirements such as durability or visual finish.

Maintenance and Longevity Considerations

Zinc plating offers superior corrosion resistance by forming a protective barrier that slows rust formation, requiring less frequent maintenance compared to chrome plating. Chrome plating provides a harder surface with high aesthetic appeal but is more prone to chipping and corrosion over time, increasing the need for regular upkeep and touch-ups. For long-term durability in harsh environments, zinc plating is often preferred due to its sacrificial corrosion protection and easier maintenance regimen.

Choosing the Right Plating for Your Product

Zinc plating offers superior corrosion resistance and cost-effectiveness, making it ideal for industrial components and automotive parts exposed to harsh environments. Chrome plating provides a highly durable, decorative finish with exceptional hardness and scratch resistance, perfect for consumer products requiring aesthetic appeal. Selecting the right plating depends on balancing factors such as environmental durability, budget constraints, and the desired surface appearance of the product.

Zinc Plating vs Chrome Plating Infographic

materialdif.com

materialdif.com