Zinc-rich primers offer superior corrosion resistance by providing a sacrificial layer that protects steel through galvanic action, making them ideal for marine and industrial environments. Zinc silicate coatings combine the protective benefits of zinc with chemical resistance and UV stability, ensuring long-term durability on exposed metal surfaces. Choosing between the two depends on the specific application requirements, with zinc-rich primers favored for heavy-duty protection and zinc silicate coatings preferred for aesthetic and weather-resistant finishes.

Table of Comparison

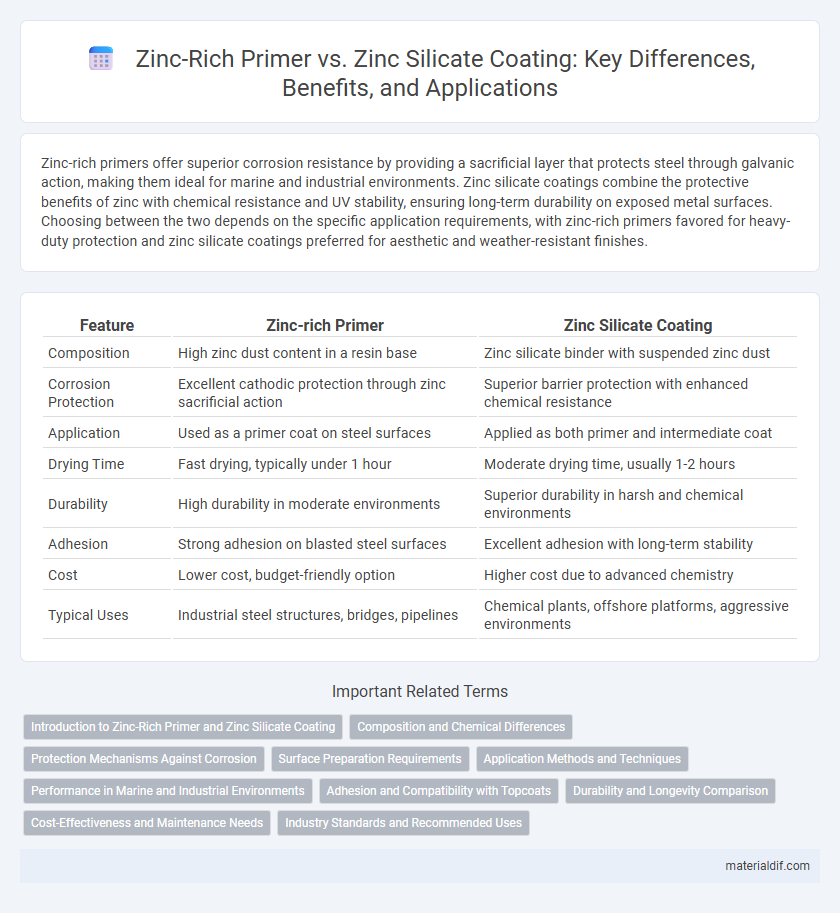

| Feature | Zinc-rich Primer | Zinc Silicate Coating |

|---|---|---|

| Composition | High zinc dust content in a resin base | Zinc silicate binder with suspended zinc dust |

| Corrosion Protection | Excellent cathodic protection through zinc sacrificial action | Superior barrier protection with enhanced chemical resistance |

| Application | Used as a primer coat on steel surfaces | Applied as both primer and intermediate coat |

| Drying Time | Fast drying, typically under 1 hour | Moderate drying time, usually 1-2 hours |

| Durability | High durability in moderate environments | Superior durability in harsh and chemical environments |

| Adhesion | Strong adhesion on blasted steel surfaces | Excellent adhesion with long-term stability |

| Cost | Lower cost, budget-friendly option | Higher cost due to advanced chemistry |

| Typical Uses | Industrial steel structures, bridges, pipelines | Chemical plants, offshore platforms, aggressive environments |

Introduction to Zinc-Rich Primer and Zinc Silicate Coating

Zinc-rich primers contain high concentrations of zinc dust that provide cathodic protection by forming a sacrificial layer on metal surfaces, preventing corrosion and extending the lifespan of steel structures. Zinc silicate coatings combine zinc with silicate binders to create a robust, chemical-resistant barrier that adheres well in harsh environments and offers excellent long-term protection against rust and oxidation. These coatings are commonly used in industrial and marine applications where both mechanical durability and corrosion resistance are critical.

Composition and Chemical Differences

Zinc-rich primers contain a high percentage of metallic zinc particles suspended in a resin binder, offering cathodic protection through the sacrificial action of zinc to prevent steel corrosion. Zinc silicate coatings feature zinc particles bonded with a silicate binder, providing enhanced chemical resistance and durability by forming a tightly adhering, inorganic matrix that resists moisture and chemicals. The primary chemical difference lies in the binder: organic resin in zinc-rich primers versus inorganic silicate in zinc silicate coatings, influencing their adhesion, resistance properties, and suitable application environments.

Protection Mechanisms Against Corrosion

Zinc-rich primers protect steel surfaces through cathodic protection, where zinc particles provide sacrificial anodes that corrode preferentially, thus preserving the underlying metal. Zinc silicate coatings create a dense, adherent barrier that combines physical isolation from moisture and oxygen with chemical passivation of the metal substrate. Both coatings enhance corrosion resistance, but zinc-rich primers excel in active protection, while zinc silicate coatings offer superior durability and environmental resistance.

Surface Preparation Requirements

Zinc-rich primers require meticulous surface preparation, including near-white metal blasting (SSPC-SP10/NACE No. 2), to ensure optimal adhesion and corrosion resistance. Zinc silicate coatings also demand stringent surface cleanliness but often necessitate a more aggressive profile, typically achieving a 75-100 micron blast profile for proper mechanical bonding. Both coatings rely heavily on removing contaminants, rust, and mill scale to maximize the protective zinc content's performance on steel substrates.

Application Methods and Techniques

Zinc-rich primers are typically applied through spraying or brushing, offering excellent adhesion and ease of use on various metal substrates, especially in shipbuilding and structural steel protection. Zinc silicate coatings require more precise surface preparation and are usually applied via airless spray or brush, providing superior corrosion resistance and durability in industrial environments. Proper application thickness and environmental conditions significantly influence the performance of both zinc-rich primers and zinc silicate coatings.

Performance in Marine and Industrial Environments

Zinc-rich primers provide superior corrosion protection in marine and industrial environments due to their high zinc content, which offers excellent galvanic protection by sacrificially corroding before the steel substrate. Zinc silicate coatings deliver enhanced durability and resistance to harsh chemicals and abrasion, making them ideal for long-term exposure to aggressive conditions. The combination of zinc-rich primers' fast curing and zinc silicate coatings' robust barrier properties ensures optimal performance in demanding environments.

Adhesion and Compatibility with Topcoats

Zinc-rich primers exhibit excellent adhesion properties due to their high zinc content, promoting strong metallurgical bonding with steel substrates, which enhances corrosion resistance. Zinc silicate coatings offer superior compatibility with a wide range of topcoats, including epoxy and polyurethane systems, ensuring durable and uniform finishing layers. Optimal coating performance is achieved by selecting zinc-rich primers for priming surfaces requiring maximum adhesion and zinc silicate coatings for applications demanding versatile topcoat integration.

Durability and Longevity Comparison

Zinc-rich primers offer excellent adhesion and sacrificial corrosion protection by providing a high zinc content that readily corrodes to protect steel substrates, resulting in moderate durability typically lasting 5 to 10 years. Zinc silicate coatings form a dense, chemical-resistant barrier with superior longevity, often exceeding 15 years in harsh environments due to their enhanced resistance to weathering and chemical exposure. The choice between the two depends on the required lifespan and environmental conditions, with zinc silicate coatings preferred for long-term, heavy-duty protection.

Cost-Effectiveness and Maintenance Needs

Zinc-rich primers offer superior cost-effectiveness due to their lower initial application cost and ease of maintenance in industrial environments. Zinc silicate coatings, while more expensive upfront, provide enhanced corrosion resistance and longer intervals between maintenance cycles, reducing long-term expenses. Choosing between the two depends on balancing immediate budget constraints with desired durability and maintenance frequency.

Industry Standards and Recommended Uses

Zinc-rich primers comply with ASTM D520 standards, offering superior corrosion resistance through high zinc content and are widely used for steel structures in marine and industrial environments. Zinc silicate coatings meet SSPC Paint 20 guidelines, providing excellent durability and chemical resistance, making them ideal for heavy-duty applications like petrochemical plants and offshore platforms. Industry standards emphasize zinc-rich primers for initial protection and zinc silicates for enhanced long-term performance in harsh conditions.

Zinc-rich Primer vs Zinc Silicate Coating Infographic

materialdif.com

materialdif.com