Zinc-Lamella coating offers superior corrosion resistance by forming a dense, uniform barrier with multiple lamella layers that protect metal surfaces more effectively than traditional zinc electroplating. Unlike zinc electroplating, which deposits a thin metallic layer prone to wear and oxidation, Zinc-Lamella relies on a chemical conversion process that enhances durability and longevity in harsh environments. This innovative coating method reduces maintenance costs and extends the lifespan of components exposed to moisture and abrasive conditions.

Table of Comparison

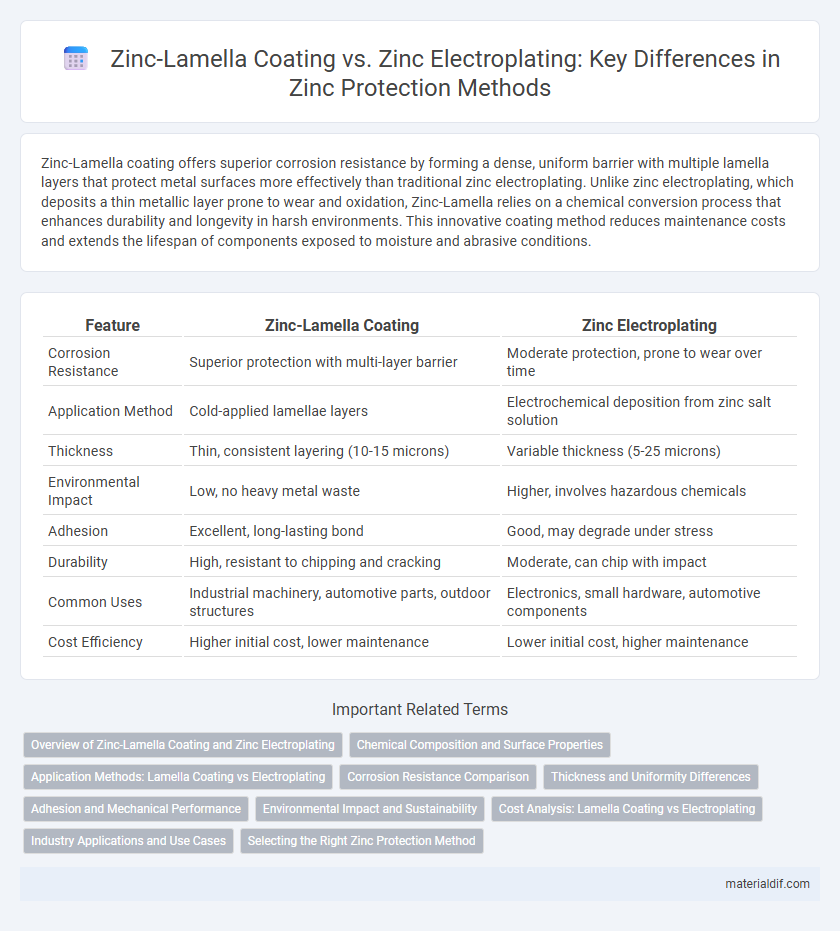

| Feature | Zinc-Lamella Coating | Zinc Electroplating |

|---|---|---|

| Corrosion Resistance | Superior protection with multi-layer barrier | Moderate protection, prone to wear over time |

| Application Method | Cold-applied lamellae layers | Electrochemical deposition from zinc salt solution |

| Thickness | Thin, consistent layering (10-15 microns) | Variable thickness (5-25 microns) |

| Environmental Impact | Low, no heavy metal waste | Higher, involves hazardous chemicals |

| Adhesion | Excellent, long-lasting bond | Good, may degrade under stress |

| Durability | High, resistant to chipping and cracking | Moderate, can chip with impact |

| Common Uses | Industrial machinery, automotive parts, outdoor structures | Electronics, small hardware, automotive components |

| Cost Efficiency | Higher initial cost, lower maintenance | Lower initial cost, higher maintenance |

Overview of Zinc-Lamella Coating and Zinc Electroplating

Zinc-Lamella coating provides a thin, layered protective barrier of pure zinc flakes that enhances corrosion resistance and maintains electrical conductivity without altering surface dimensions. Zinc electroplating involves depositing a uniform zinc layer through an electrochemical process, offering robust corrosion protection and improved adhesion on metal substrates. Both methods serve as effective zinc-based surface treatments, with Zinc-Lamella favored for its eco-friendly, non-electrolytic application and Zinc electroplating excelling in creating thicker, more durable coatings.

Chemical Composition and Surface Properties

Zinc-Lamella coating consists primarily of pure zinc flakes embedded in a binder, providing a non-electrolytic, layered structure that enhances corrosion resistance through barrier and sacrificial protection. Zinc electroplating involves depositing a metallic zinc layer via an electrolytic process, resulting in a uniform, dense coating with strong adhesion and increased surface hardness. The lamellar morphology of Zinc-Lamella coatings offers superior flexibility and self-healing properties, whereas zinc electroplating produces a smoother finish ideal for aesthetic applications but can be prone to microcracks under mechanical stress.

Application Methods: Lamella Coating vs Electroplating

Zinc-Lamella coating involves a mechanical bonding process where zinc flakes create a protective barrier on surfaces without requiring electrical current, making it suitable for complex geometries and quick application. Zinc electroplating uses an electrolytic bath to deposit a uniform zinc layer through electrical current, offering precise thickness control ideal for high corrosion resistance in automotive and industrial parts. The choice between lamella coating and electroplating depends on factors like substrate shape, desired coating durability, and environmental resistance requirements.

Corrosion Resistance Comparison

Zinc-lamella coating offers superior corrosion resistance by providing a multi-layered protective barrier that reduces direct metal exposure and enhances durability against harsh environments. Zinc electroplating, while effective, typically forms a single uniform layer susceptible to wear and damage, leading to faster corrosion onset under prolonged exposure. Studies indicate zinc-lamella coatings can extend corrosion resistance lifespan by up to 50% compared to traditional zinc electroplated surfaces.

Thickness and Uniformity Differences

Zinc-Lamella coating typically provides a thicker and more uniform layer compared to traditional zinc electroplating, enhancing corrosion resistance and durability. The lamella process achieves a consistent coating thickness, often ranging between 10 to 30 microns, whereas zinc electroplating thickness varies more widely, generally between 5 to 15 microns. Uniformity in zinc-lamella coatings reduces weak spots and improves long-term performance in harsh environments.

Adhesion and Mechanical Performance

Zinc-lamella coating provides superior adhesion and enhanced mechanical performance compared to traditional zinc electroplating due to its multilayer structure that promotes stronger bonding with the substrate. This coating method improves resistance to abrasion, corrosion, and mechanical stresses, making it suitable for demanding industrial applications. In contrast, zinc electroplating often exhibits weaker adhesion and can be prone to cracking or flaking under mechanical strain.

Environmental Impact and Sustainability

Zinc-lamella coating offers a more environmentally sustainable alternative to traditional zinc electroplating by minimizing hazardous waste and reducing water pollution from heavy metal runoff. The lamella process uses fewer chemicals and consumes less energy, significantly decreasing the carbon footprint associated with surface protection. Its longer-lasting corrosion resistance also reduces the need for frequent recoating, contributing to lower material consumption and waste generation in industrial applications.

Cost Analysis: Lamella Coating vs Electroplating

Zinc-Lamella coating offers a cost-effective alternative to traditional zinc electroplating by reducing energy consumption and eliminating the need for hazardous chemical baths, lowering operational expenses. While zinc electroplating provides superior thickness and corrosion resistance, its higher installation and maintenance costs impact long-term budget considerations. Companies prioritize Zinc-Lamella coating for projects demanding economical coating solutions with moderate protection levels against corrosion.

Industry Applications and Use Cases

Zinc-Lamella coating delivers superior corrosion resistance and is widely used in automotive, construction, and industrial machinery due to its eco-friendly, non-electrolytic application process. Zinc electroplating remains prevalent in electronics, fasteners, and hardware manufacturing for its cost-effectiveness and uniform metallic finish. Industries prioritize Zinc-Lamella for environmentally sensitive projects requiring durable protection, while Zinc electroplating suits high-volume production where conductivity and appearance are critical.

Selecting the Right Zinc Protection Method

Zinc-Lamella coating offers a uniform, chrome-free corrosion protection with excellent adhesion, ideal for automotive and industrial applications requiring environmentally friendly solutions. Zinc electroplating provides a cost-effective, conductive layer suitable for electrical components and parts exposed to moderate corrosion. Selecting the right zinc protection method depends on factors such as exposure conditions, environmental regulations, and required durability.

Zinc-Lamella Coating vs Zinc Electroplating Infographic

materialdif.com

materialdif.com