Cold galvanizing involves applying a zinc-rich paint or coating at room temperature, providing corrosion resistance through a sacrificial barrier. Hot galvanizing, on the other hand, entails dipping steel into molten zinc, creating a robust, metallurgically bonded layer that offers superior durability and longevity. Choosing between cold and hot galvanizing depends on the desired protection level, application method, and environmental conditions.

Table of Comparison

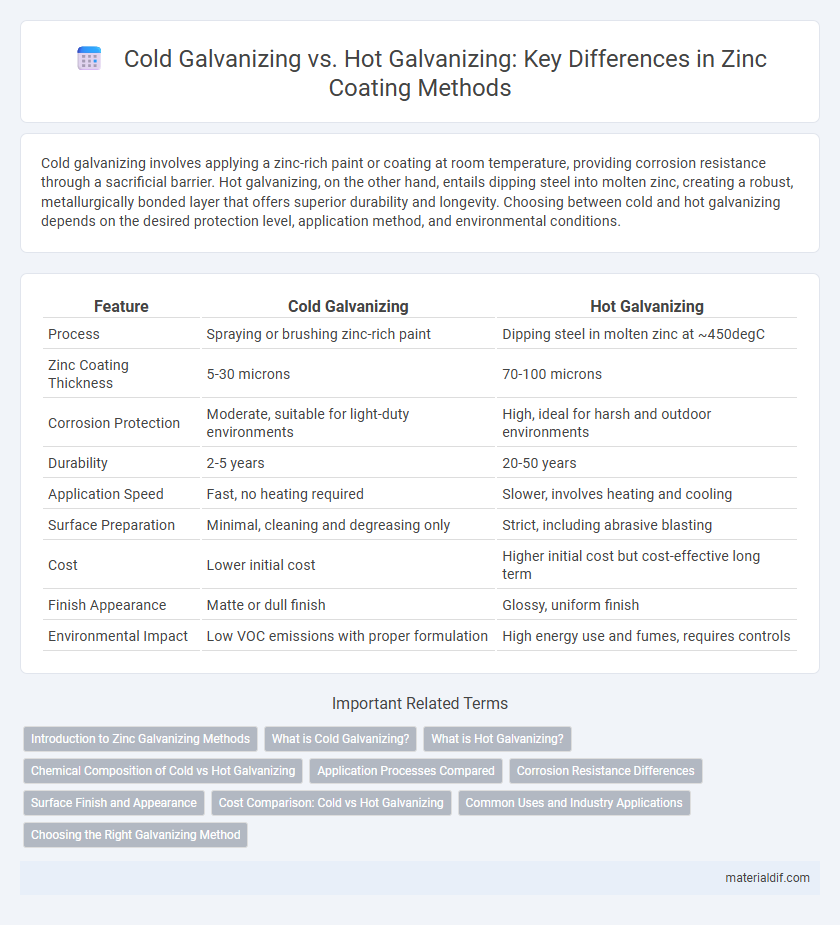

| Feature | Cold Galvanizing | Hot Galvanizing |

|---|---|---|

| Process | Spraying or brushing zinc-rich paint | Dipping steel in molten zinc at ~450degC |

| Zinc Coating Thickness | 5-30 microns | 70-100 microns |

| Corrosion Protection | Moderate, suitable for light-duty environments | High, ideal for harsh and outdoor environments |

| Durability | 2-5 years | 20-50 years |

| Application Speed | Fast, no heating required | Slower, involves heating and cooling |

| Surface Preparation | Minimal, cleaning and degreasing only | Strict, including abrasive blasting |

| Cost | Lower initial cost | Higher initial cost but cost-effective long term |

| Finish Appearance | Matte or dull finish | Glossy, uniform finish |

| Environmental Impact | Low VOC emissions with proper formulation | High energy use and fumes, requires controls |

Introduction to Zinc Galvanizing Methods

Zinc galvanizing methods primarily include cold galvanizing and hot galvanizing, both designed to protect steel from corrosion. Cold galvanizing applies a zinc-rich paint containing high percentages of zinc dust, creating a barrier and sacrificial layer. Hot galvanizing, also known as hot-dip galvanizing, involves immersing steel in molten zinc at approximately 450degC, forming a metallurgical bond for superior durability and corrosion resistance.

What is Cold Galvanizing?

Cold galvanizing is a zinc-rich coating process that involves applying a zinc-based paint or spray to steel surfaces, providing sacrificial protection against corrosion without the need for high-temperature treatment. Unlike hot galvanizing, which immerses steel in molten zinc at temperatures around 450degC, cold galvanizing offers a more convenient and cost-effective solution for touch-ups and maintenance. This method ensures a durable zinc barrier that prevents rust formation while maintaining the metal's structural integrity.

What is Hot Galvanizing?

Hot galvanizing is a process where steel or iron is immersed in molten zinc at temperatures around 450degC, creating a robust metallurgical bond that provides superior corrosion resistance. This method forms multiple zinc-iron alloy layers, resulting in a thicker and more durable coating compared to cold galvanizing. Hot galvanizing is widely used in industrial applications requiring long-lasting protection against rust and environmental damage.

Chemical Composition of Cold vs Hot Galvanizing

Cold galvanizing primarily uses a zinc-rich paint composed of finely powdered zinc and organic binders, creating a protective layer through cathodic action without melting the metal. Hot galvanizing involves immersing steel in molten zinc at around 450degC, forming a metallurgical bond through the diffusion of zinc-iron alloys that enhances corrosion resistance. The chemical composition of hot galvanizing results in a thicker, more durable zinc-iron alloy coating, whereas cold galvanizing offers a thinner layer rich in elemental zinc particles for surface protection.

Application Processes Compared

Cold galvanizing involves applying a zinc-rich paint or coating at room temperature, offering ease of use and suitability for touch-ups or small-scale projects. Hot galvanizing requires immersing steel in molten zinc at temperatures around 450degC, creating a thick, metallurgically bonded coating ideal for heavy-duty corrosion protection. Cold galvanizing provides a thinner, less durable layer compared to the robust, long-lasting finish produced by hot galvanizing processes.

Corrosion Resistance Differences

Cold galvanizing applies zinc-rich paint to steel surfaces, providing sacrificial protection through zinc particles that slowly corrode instead of the base metal, offering moderate corrosion resistance primarily suited for less aggressive environments. Hot galvanizing involves immersing steel in molten zinc at around 450degC, forming a metallurgical bond with multiple zinc-iron alloy layers that deliver superior, long-lasting corrosion resistance, especially in harsh or marine conditions. The dense, tightly adherent coating from hot galvanizing significantly outperforms cold galvanizing's paint-like layer in protecting steel against rust and environmental degradation.

Surface Finish and Appearance

Cold galvanizing offers a matte, non-reflective surface finish due to the zinc-rich paint application, providing protective corrosion resistance without altering the base metal's texture. Hot galvanizing produces a smoother, more uniform, and shiny surface with a thicker zinc coating formed by immersion in molten zinc, creating a durable, corrosion-resistant layer with a metallic luster. Surface appearance in cold galvanizing tends to be less consistent and more porous compared to the seamless, glossy finish of hot galvanizing.

Cost Comparison: Cold vs Hot Galvanizing

Cold galvanizing typically incurs lower initial costs due to its simplicity and minimal equipment requirements, making it attractive for small-scale or touch-up applications. Hot galvanizing involves higher upfront expenses from heating zinc to its molten state and specialized facilities but offers superior durability and longer service life, potentially reducing long-term maintenance costs. Overall, cold galvanizing is cost-effective for light protection, while hot galvanizing provides greater value in heavy-duty environments despite higher initial investment.

Common Uses and Industry Applications

Cold galvanizing is commonly used for touch-ups and thin-film corrosion protection on automotive parts, machinery, and structural steel where ease of application and flexibility are essential. Hot galvanizing is preferred in heavy industry sectors like construction, infrastructure, and shipbuilding due to its thick, durable zinc coating that offers long-lasting rust resistance. Both methods find extensive use in the marine and oil industries, ensuring steel components withstand harsh environmental conditions.

Choosing the Right Galvanizing Method

Cold galvanizing uses zinc-rich paint to provide a corrosion-resistant coating ideal for touch-ups and thin applications, offering ease of use and flexibility. Hot galvanizing involves immersing steel in molten zinc, creating a thick, durable, and long-lasting protective layer suitable for heavy-duty industrial structures exposed to harsh environments. Choosing between cold and hot galvanizing depends on factors like the required corrosion resistance, structural demands, environmental exposure, and budget considerations.

Cold Galvanizing vs Hot Galvanizing Infographic

materialdif.com

materialdif.com