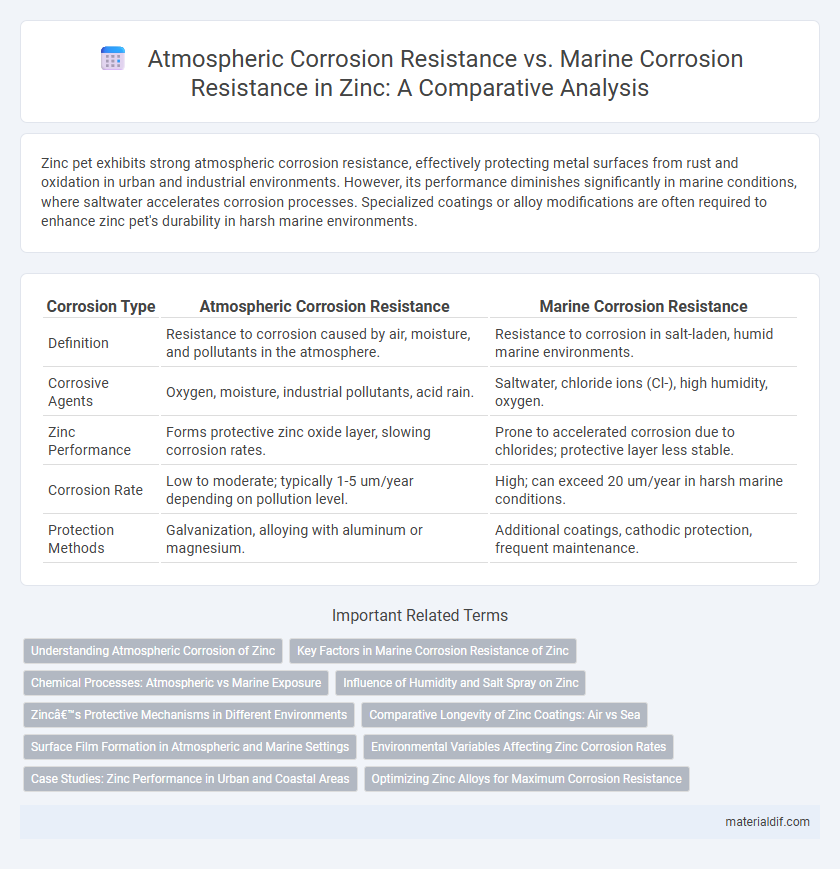

Zinc pet exhibits strong atmospheric corrosion resistance, effectively protecting metal surfaces from rust and oxidation in urban and industrial environments. However, its performance diminishes significantly in marine conditions, where saltwater accelerates corrosion processes. Specialized coatings or alloy modifications are often required to enhance zinc pet's durability in harsh marine environments.

Table of Comparison

| Corrosion Type | Atmospheric Corrosion Resistance | Marine Corrosion Resistance |

|---|---|---|

| Definition | Resistance to corrosion caused by air, moisture, and pollutants in the atmosphere. | Resistance to corrosion in salt-laden, humid marine environments. |

| Corrosive Agents | Oxygen, moisture, industrial pollutants, acid rain. | Saltwater, chloride ions (Cl-), high humidity, oxygen. |

| Zinc Performance | Forms protective zinc oxide layer, slowing corrosion rates. | Prone to accelerated corrosion due to chlorides; protective layer less stable. |

| Corrosion Rate | Low to moderate; typically 1-5 um/year depending on pollution level. | High; can exceed 20 um/year in harsh marine conditions. |

| Protection Methods | Galvanization, alloying with aluminum or magnesium. | Additional coatings, cathodic protection, frequent maintenance. |

Understanding Atmospheric Corrosion of Zinc

Zinc exhibits superior atmospheric corrosion resistance due to the formation of a stable, adherent oxide layer that protects the metal surface from further oxidation. In marine environments, the presence of chloride ions accelerates zinc corrosion by disrupting this protective layer, leading to increased material degradation. Understanding the mechanisms of atmospheric corrosion in zinc is essential for optimizing its use in protective coatings and extending the lifespan of metal structures exposed to various environmental conditions.

Key Factors in Marine Corrosion Resistance of Zinc

Zinc demonstrates superior marine corrosion resistance primarily due to its ability to form a stable, adherent zinc carbonate patina that protects the underlying metal from aggressive chloride ions in seawater. The key factors influencing this resistance include high salinity tolerance, continuous formation of protective corrosion products, and zinc's sacrificial anode behavior in galvanic corrosion protection systems. Furthermore, alloying elements and controlled deposition processes enhance zinc's durability in harsh marine environments by improving barrier properties and reducing pitting susceptibility.

Chemical Processes: Atmospheric vs Marine Exposure

Zinc exhibits distinct chemical processes in atmospheric versus marine corrosion resistance, where atmospheric exposure primarily involves oxidation forming a protective zinc carbonate layer that limits further degradation. In marine environments, chloride ions from saltwater accelerate corrosion by breaching this protective film, leading to the formation of zinc chloride complexes and subsequent increased metal loss. The kinetics of zinc corrosion in marine settings are significantly higher due to constant moisture, salt concentration, and oxygen availability, which intensify electrochemical reactions compared to variable atmospheric conditions.

Influence of Humidity and Salt Spray on Zinc

Zinc exhibits superior atmospheric corrosion resistance due to the formation of a stable oxide layer that protects the underlying metal, especially in environments with moderate humidity levels. In marine environments, high salt spray concentrations accelerate zinc corrosion by promoting electrochemical reactions and disrupting the protective oxide film. The combined effects of elevated humidity and salt spray significantly reduce zinc's lifespan compared to dry or less saline atmospheric exposure.

Zinc’s Protective Mechanisms in Different Environments

Zinc exhibits superior atmospheric corrosion resistance due to its ability to form a stable, adherent oxide layer that shields underlying metals from moisture and airborne pollutants. In marine environments, zinc's sacrificial anodic behavior protects steel substrates by preferentially corroding, thereby preventing rust formation despite constant exposure to saltwater and chloride ions. The differential corrosion mechanisms highlight zinc's dual role as both a barrier and a sacrificial anode, optimizing its protective efficacy in diverse corrosive conditions.

Comparative Longevity of Zinc Coatings: Air vs Sea

Zinc coatings exhibit significantly higher atmospheric corrosion resistance compared to marine environments, where saltwater accelerates corrosion processes. In typical air exposure, zinc can last up to 25 years as a protective barrier, whereas in marine conditions, the longevity typically reduces to 5-10 years due to chloride-induced corrosion. The comparative longevity underscores the critical influence of environmental factors on zinc's protective performance, necessitating specialized coatings or maintenance for marine applications.

Surface Film Formation in Atmospheric and Marine Settings

Zinc forms a protective surface film of zinc carbonate in atmospheric environments, enhancing its corrosion resistance by acting as a barrier to oxygen and moisture. In marine settings, the surface film primarily consists of zinc hydroxide and chloride compounds, which are less stable due to continuous exposure to saltwater, resulting in accelerated corrosion rates. The variations in film composition and stability critically influence zinc's performance in atmospheric versus marine corrosion resistance applications.

Environmental Variables Affecting Zinc Corrosion Rates

Zinc exhibits higher corrosion rates in marine environments due to elevated chloride ion concentration, increased humidity, and salt spray exposure, which accelerate galvanic and pitting corrosion. Atmospheric corrosion resistance of zinc improves in industrial or rural settings with lower pollutant levels, reduced moisture, and minimal suspended particulate matter. Temperature, relative humidity, salt deposition rate, and presence of sulfur dioxide critically influence zinc's corrosion behavior across diverse atmospheric conditions.

Case Studies: Zinc Performance in Urban and Coastal Areas

Zinc demonstrates superior atmospheric corrosion resistance in urban environments due to its stable oxide layer, which effectively minimizes degradation from industrial pollutants and acid rain. Case studies in coastal areas reveal that zinc's performance declines under marine exposure, primarily because of high chloride ion concentrations accelerating corrosion processes. However, protective coatings and alloying elements have been shown to enhance zinc's durability against the aggressive conditions typical of marine atmospheres.

Optimizing Zinc Alloys for Maximum Corrosion Resistance

Zinc alloys optimized for maximum corrosion resistance demonstrate superior performance in both atmospheric and marine environments by balancing elements such as aluminum, magnesium, and copper to enhance sacrificial protection and barrier properties. In atmospheric conditions, zinc alloys with higher aluminum content form stable, adherent oxide layers, while marine corrosion resistance relies on controlled alloying to minimize pitting and galvanic corrosion caused by chloride ions. Advanced microstructural engineering and precise alloy composition tuning enable zinc-based materials to maintain durable corrosion resistance, extending service life in harsh marine atmospheres and urban air exposure.

Atmospheric Corrosion Resistance vs Marine Corrosion Resistance Infographic

materialdif.com

materialdif.com