Zinc spray offers quick, easy application and superior adhesion for repairing small areas, providing effective corrosion resistance on metal surfaces. Zinc paint, on the other hand, is ideal for larger surfaces and prolonged protection, forming a durable barrier against rust with a thicker coating. Choosing between zinc spray and zinc paint depends on the size of the project and the level of protection needed for metal maintenance.

Table of Comparison

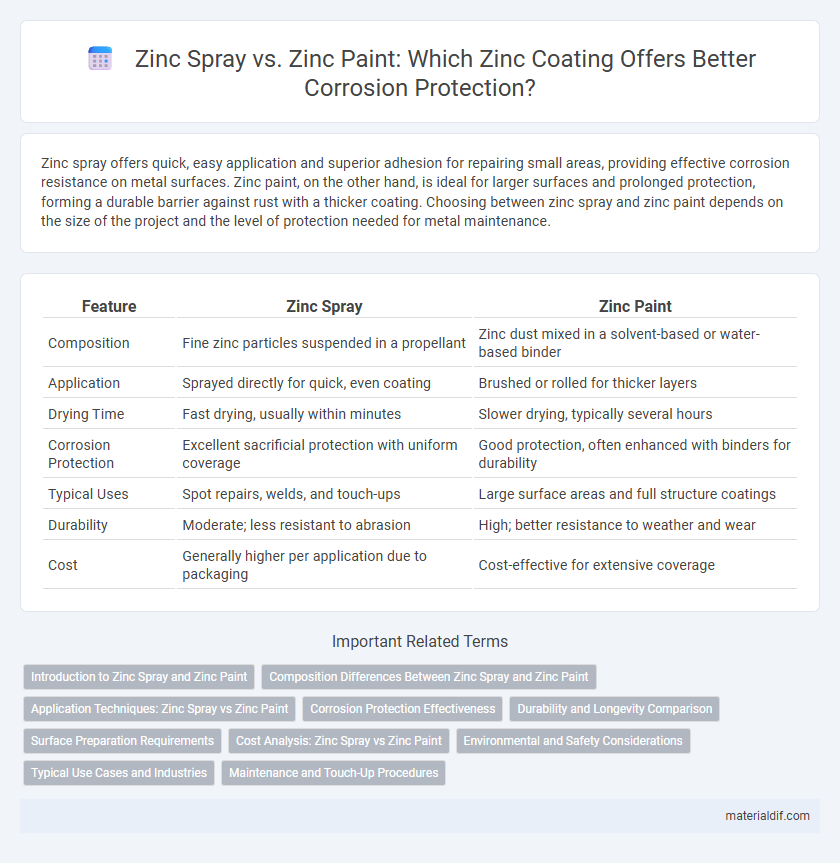

| Feature | Zinc Spray | Zinc Paint |

|---|---|---|

| Composition | Fine zinc particles suspended in a propellant | Zinc dust mixed in a solvent-based or water-based binder |

| Application | Sprayed directly for quick, even coating | Brushed or rolled for thicker layers |

| Drying Time | Fast drying, usually within minutes | Slower drying, typically several hours |

| Corrosion Protection | Excellent sacrificial protection with uniform coverage | Good protection, often enhanced with binders for durability |

| Typical Uses | Spot repairs, welds, and touch-ups | Large surface areas and full structure coatings |

| Durability | Moderate; less resistant to abrasion | High; better resistance to weather and wear |

| Cost | Generally higher per application due to packaging | Cost-effective for extensive coverage |

Introduction to Zinc Spray and Zinc Paint

Zinc spray and zinc paint are corrosion protection products used primarily in metal maintenance and repair. Zinc spray consists of fine zinc particles suspended in an aerosol, offering quick and highly adherent zinc coating ideal for spot repairs and welding joints. Zinc paint contains zinc dust mixed in a liquid binder, creating a protective layer that provides long-term corrosion resistance on larger surfaces and structural steel.

Composition Differences Between Zinc Spray and Zinc Paint

Zinc spray typically contains finely ground zinc particles suspended in a solvent or binder, allowing for easy application and rapid drying with a metallic finish, primarily used for galvanizing steel surfaces. Zinc paint, in contrast, is a blend of zinc dust mixed with pigments, resins, and solvents, offering more color variation and additional protective properties beyond corrosion resistance. The key composition difference lies in the zinc particle size and the binder system, influencing durability, adhesion, and application methods in industrial and maintenance settings.

Application Techniques: Zinc Spray vs Zinc Paint

Zinc spray offers a quick and even application, ideal for small touch-ups and irregular surfaces, utilizing aerosol or pneumatic tools to create a thin, consistent protective layer. Zinc paint requires thorough surface preparation and brush or roller application, making it better suited for larger areas and providing a thicker, more durable coating. Both methods serve as effective corrosion barriers, but zinc spray excels in precision and ease, while zinc paint ensures enhanced coverage and longevity.

Corrosion Protection Effectiveness

Zinc spray provides a thin, uniform layer of zinc that offers excellent sacrificial protection by rapidly corroding before the underlying metal, ideal for repairing welds and irregular surfaces. Zinc paint, containing zinc-rich pigments, creates a thicker protective coating that acts as a physical barrier and provides long-term corrosion resistance on larger, less detailed surfaces. The choice between zinc spray and zinc paint depends on the specific application, environmental exposure, and required durability, with zinc spray excelling in spot repairs and zinc paint suited for broad, protective coverage.

Durability and Longevity Comparison

Zinc spray offers superior adhesion and corrosion resistance, ensuring longer durability on metal surfaces compared to zinc paint, which tends to wear off faster under harsh environmental conditions. Zinc spray provides a uniform and dense protective layer that withstands weathering and mechanical abrasion more effectively than the thicker, less flexible zinc paint coatings. Longevity tests reveal zinc spray can extend the lifespan of steel structures by up to 50% longer than traditional zinc paint applications.

Surface Preparation Requirements

Zinc spray requires thorough surface preparation including abrasive blasting to achieve a clean, rust-free, and roughened substrate for optimal adhesion and corrosion resistance. Zinc paint, while still benefiting from surface cleaning and minor rust removal, typically allows for less intensive preparation such as wire brushing or solvent wiping. Proper surface preparation directly impacts the durability and protective performance of zinc coatings in industrial and marine environments.

Cost Analysis: Zinc Spray vs Zinc Paint

Zinc spray generally incurs higher upfront costs due to specialized application equipment and labor intensity, while zinc paint offers a more cost-effective option with easier application and reduced preparation time. Zinc paint typically provides adequate corrosion protection at a lower price point, making it suitable for large surface areas with budget constraints. The choice between zinc spray and zinc paint ultimately depends on project scale, desired coating thickness, and long-term maintenance expenses.

Environmental and Safety Considerations

Zinc spray offers superior environmental benefits due to its lower volatile organic compound (VOC) emissions compared to traditional zinc paint, reducing air pollution and worker exposure risks. Zinc paint often contains solvents and hazardous chemicals that require careful handling and disposal to prevent soil and water contamination. Choosing zinc spray can enhance workplace safety by minimizing toxic fumes and providing better control over application, thereby limiting environmental impact.

Typical Use Cases and Industries

Zinc spray is commonly used for protective coatings in automotive, industrial machinery, and marine sectors due to its excellent corrosion resistance and ease of on-site application. Zinc paint finds typical use in construction and infrastructure projects, such as steel frameworks and bridges, offering durable protection during fabrication and maintenance phases. Both products serve critical roles in extending metal longevity in harsh environmental conditions, with zinc spray favored for repair work and zinc paint for full-surface coverage.

Maintenance and Touch-Up Procedures

Zinc spray provides a quick-drying, easy-to-apply protective layer ideal for irregular surfaces, facilitating straightforward maintenance and touch-up by simply reapplying the spray on damaged areas. Zinc paint, often thicker and more durable, requires surface preparation and careful application during touch-ups to ensure proper adhesion and corrosion resistance. Both methods effectively restore zinc protection, but zinc spray offers superior convenience for frequent or small-scale maintenance tasks.

Zinc Spray vs Zinc Paint Infographic

materialdif.com

materialdif.com