Hot-dip galvanizing involves immersing steel in molten zinc, creating a thick, durable coating that offers superior corrosion resistance and long-lasting protection. Cold galvanizing uses zinc-rich paint applied to metal surfaces, providing a thinner layer suitable for touch-ups and less intensive environments. Hot-dip galvanizing is ideal for heavy-duty applications exposed to harsh conditions, while cold galvanizing is better suited for maintenance and light-duty corrosion control.

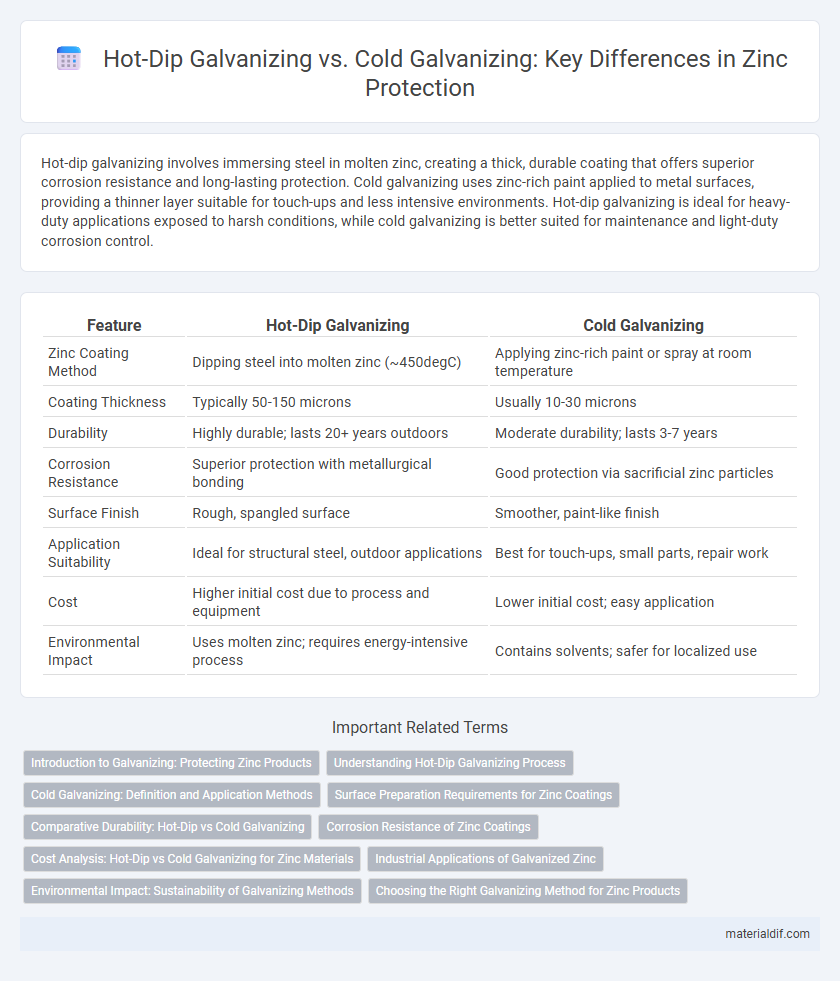

Table of Comparison

| Feature | Hot-Dip Galvanizing | Cold Galvanizing |

|---|---|---|

| Zinc Coating Method | Dipping steel into molten zinc (~450degC) | Applying zinc-rich paint or spray at room temperature |

| Coating Thickness | Typically 50-150 microns | Usually 10-30 microns |

| Durability | Highly durable; lasts 20+ years outdoors | Moderate durability; lasts 3-7 years |

| Corrosion Resistance | Superior protection with metallurgical bonding | Good protection via sacrificial zinc particles |

| Surface Finish | Rough, spangled surface | Smoother, paint-like finish |

| Application Suitability | Ideal for structural steel, outdoor applications | Best for touch-ups, small parts, repair work |

| Cost | Higher initial cost due to process and equipment | Lower initial cost; easy application |

| Environmental Impact | Uses molten zinc; requires energy-intensive process | Contains solvents; safer for localized use |

Introduction to Galvanizing: Protecting Zinc Products

Hot-dip galvanizing involves immersing steel or iron in molten zinc at temperatures around 450degC, forming a durable, corrosion-resistant alloy layer that enhances the longevity of zinc-coated products. Cold galvanizing, also known as zinc-rich painting, applies a zinc-containing paint at ambient temperature, offering surface protection without metallurgical bonding. Both methods protect zinc products by creating a barrier against oxidation and environmental damage, but hot-dip galvanizing provides superior mechanical adhesion and thicker zinc layers for more robust corrosion resistance.

Understanding Hot-Dip Galvanizing Process

The hot-dip galvanizing process involves immersing steel or iron in molten zinc at approximately 450degC, creating a metallurgical bond that offers superior corrosion resistance compared to cold galvanizing. This method produces a thicker, more durable coating with layers of zinc-iron alloys that tightly adhere to the base metal, enhancing protection in harsh environments. Hot-dip galvanizing ensures uniform coverage, especially on complex shapes and welded joints, making it ideal for long-term structural applications.

Cold Galvanizing: Definition and Application Methods

Cold galvanizing involves the application of zinc-rich paint to steel surfaces, providing corrosion protection through the sacrificial nature of zinc particles in the coating. This method is typically applied by brushing, rolling, or spraying zinc-rich primers onto clean, prepared metal surfaces, offering ease of use and quick touch-up capabilities. Cold galvanizing is especially effective for maintenance and repair of galvanized steel structures where hot-dip galvanizing is impractical.

Surface Preparation Requirements for Zinc Coatings

Hot-dip galvanizing requires thorough surface preparation, including abrasive blasting to remove mill scale, rust, and contaminants, ensuring optimal adhesion of the zinc coating. Cold galvanizing involves minimal surface preparation, usually limited to cleaning or light sanding, as it relies on zinc-rich paint formulations rather than metallurgical bonding. Proper surface preparation significantly influences the corrosion protection performance of both hot-dip and cold galvanized zinc coatings.

Comparative Durability: Hot-Dip vs Cold Galvanizing

Hot-dip galvanizing creates a thicker, metallurgically bonded zinc coating that provides superior corrosion resistance and durability compared to cold galvanizing, which relies on a thinner, sprayed or brush-applied zinc layer. The heat-induced diffusion process in hot-dip galvanizing produces multiple zinc-iron alloy layers, resulting in enhanced abrasion resistance and longer service life in harsh environments. Cold galvanizing, while easier to apply and suitable for touch-ups, offers less protection against mechanical damage and corrosion, making it less durable for heavy-duty applications.

Corrosion Resistance of Zinc Coatings

Hot-dip galvanizing involves immersing steel in molten zinc, creating a thick, metallurgically bonded coating that provides superior corrosion resistance through multiple zinc-iron alloy layers protecting the substrate. Cold galvanizing, which applies zinc-rich paint, offers corrosion protection primarily through the sacrificial properties of zinc particles but forms a thinner, less durable barrier compared to hot-dip galvanizing. The dense, uniform zinc coating from hot-dip galvanizing significantly enhances long-term corrosion resistance in harsh environments compared to the more superficial protection of cold galvanizing.

Cost Analysis: Hot-Dip vs Cold Galvanizing for Zinc Materials

Hot-dip galvanizing generally incurs higher initial costs due to the extensive heating and immersion processes, making it more expensive than cold galvanizing, which involves applying zinc-rich paint at ambient temperatures. Despite the upfront expense, hot-dip galvanizing offers superior durability and corrosion resistance, often translating to lower maintenance and lifecycle costs compared to cold galvanizing's more frequent touch-ups and reapplications. Evaluating total ownership cost, hot-dip galvanizing typically provides greater long-term economic efficiency for zinc-coated materials, especially in highly corrosive environments.

Industrial Applications of Galvanized Zinc

Hot-dip galvanizing offers superior corrosion resistance and is widely used in heavy industrial applications such as construction, automotive manufacturing, and infrastructure due to its thick, durable zinc coating. Cold galvanizing, often applied by spray, suits smaller-scale maintenance and repair work where rapid application and flexibility are critical, including electrical equipment and metal furniture. Both methods protect steel surfaces from oxidation, but hot-dip galvanizing excels in long-term durability for harsh environments.

Environmental Impact: Sustainability of Galvanizing Methods

Hot-dip galvanizing involves coating steel with a thick layer of molten zinc, offering long-lasting corrosion protection that reduces the need for frequent maintenance and replacements, thereby minimizing environmental waste. Cold galvanizing uses zinc-rich paint that, while easier to apply, provides a thinner protective layer that may require more frequent reapplications, increasing material consumption and emissions over time. The sustainability of hot-dip galvanizing is generally higher due to its durability and recyclability of zinc, which lowers ecological footprints compared to the consumable nature of cold galvanizing coatings.

Choosing the Right Galvanizing Method for Zinc Products

Hot-dip galvanizing offers a thicker, more durable zinc coating by immersing steel in molten zinc, providing superior corrosion resistance ideal for heavy-duty applications. Cold galvanizing involves applying zinc-rich paint at room temperature, offering ease of application and effective protection for lighter, less exposed zinc products. Selecting the right method depends on the product's exposure level, desired durability, and application environment to ensure optimal zinc coating performance.

Hot-Dip Galvanizing vs Cold Galvanizing Infographic

materialdif.com

materialdif.com