Trivalent chromate offers a safer and more environmentally friendly alternative to hexavalent chromate in zinc plating applications, providing effective corrosion resistance with significantly lower toxicity. The use of trivalent chromate reduces health risks associated with hexavalent chromate, which is known for its carcinogenic properties and stricter regulatory restrictions. Selecting trivalent chromate enhances worker safety and compliance while maintaining the protective qualities essential for zinc-coated surfaces.

Table of Comparison

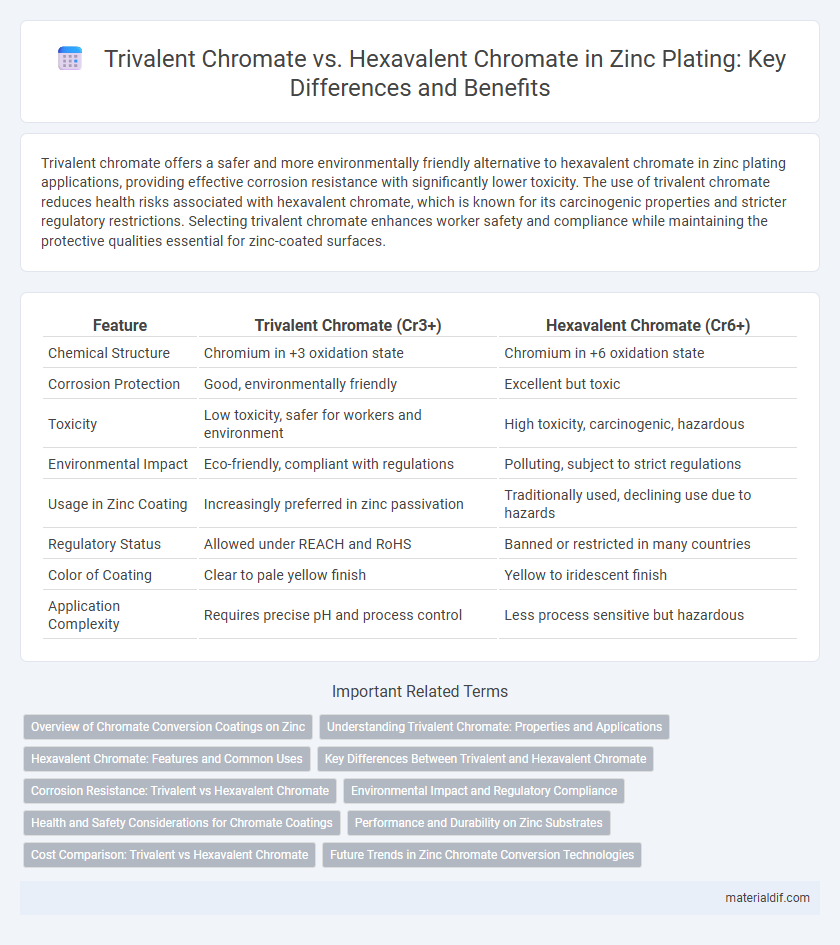

| Feature | Trivalent Chromate (Cr3+) | Hexavalent Chromate (Cr6+) |

|---|---|---|

| Chemical Structure | Chromium in +3 oxidation state | Chromium in +6 oxidation state |

| Corrosion Protection | Good, environmentally friendly | Excellent but toxic |

| Toxicity | Low toxicity, safer for workers and environment | High toxicity, carcinogenic, hazardous |

| Environmental Impact | Eco-friendly, compliant with regulations | Polluting, subject to strict regulations |

| Usage in Zinc Coating | Increasingly preferred in zinc passivation | Traditionally used, declining use due to hazards |

| Regulatory Status | Allowed under REACH and RoHS | Banned or restricted in many countries |

| Color of Coating | Clear to pale yellow finish | Yellow to iridescent finish |

| Application Complexity | Requires precise pH and process control | Less process sensitive but hazardous |

Overview of Chromate Conversion Coatings on Zinc

Trivalent chromate conversion coatings on zinc provide a less toxic alternative to hexavalent chromate coatings, offering effective corrosion resistance with reduced environmental and health risks. These coatings chemically react with the zinc surface, forming a passive layer that enhances adhesion and extends the lifespan of zinc-plated components. Hexavalent chromate, while traditionally used for superior protection, faces regulatory restrictions due to its carcinogenic nature, driving the industry toward trivalent chromate solutions.

Understanding Trivalent Chromate: Properties and Applications

Trivalent chromate (Cr(III)) is a less toxic and environmentally friendly alternative to hexavalent chromate (Cr(VI)) commonly used in zinc plating and corrosion resistance coatings. Trivalent chromate offers superior compatibility with zinc substrates, forming stable passivation layers that enhance corrosion protection while reducing health hazards associated with chromium exposure. Industrial applications of trivalent chromate include automotive finishes, architectural metals, and electronics, where regulatory compliance with RoHS and REACH standards drives its adoption over hexavalent chromate.

Hexavalent Chromate: Features and Common Uses

Hexavalent chromate (Cr(VI)) is a highly toxic and carcinogenic compound characterized by its strong oxidizing properties and bright yellow color. It is commonly used in corrosion-resistant coatings, electroplating, and pigment production due to its superior durability and chemical stability. Regulatory restrictions are increasingly limiting hexavalent chromate use because of environmental and health concerns, prompting a shift towards safer alternatives like trivalent chromate.

Key Differences Between Trivalent and Hexavalent Chromate

Trivalent chromate (Cr(III)) is less toxic and more environmentally friendly compared to hexavalent chromate (Cr(VI)), which is highly toxic and carcinogenic. Cr(III) exhibits better corrosion resistance in zinc coatings by forming stable, non-soluble compounds, whereas Cr(VI) provides superior but hazardous passivation properties. Regulatory restrictions increasingly favor the use of trivalent chromates due to their lower environmental impact and reduced health risks.

Corrosion Resistance: Trivalent vs Hexavalent Chromate

Trivalent chromate coatings provide effective corrosion resistance while offering a safer, environmentally friendly alternative to hexavalent chromate, which is highly toxic and carcinogenic. Trivalent chromate forms a stable, passivating layer on zinc surfaces, significantly reducing corrosion without the environmental and regulatory concerns associated with hexavalent chromate. Hexavalent chromate, though historically favored for its superior corrosion protection, is being phased out due to strict regulations, prompting widespread adoption of trivalent chromate in corrosion-resistant zinc plating applications.

Environmental Impact and Regulatory Compliance

Trivalent chromate coatings offer significantly lower environmental risks compared to hexavalent chromate, which is highly toxic and carcinogenic, leading to strict regulatory restrictions under frameworks like REACH and RoHS. Trivalent chromate provides effective corrosion resistance for zinc surfaces while minimizing hazardous waste and air pollutants, facilitating compliance with stringent environmental standards. Adopting trivalent chromate aligns with global initiatives to reduce heavy metal pollution and enables manufacturers to meet evolving industrial safety and sustainability criteria efficiently.

Health and Safety Considerations for Chromate Coatings

Trivalent chromate coatings exhibit significantly lower toxicity compared to hexavalent chromate, reducing the risk of carcinogenic exposure and environmental contamination in zinc plating applications. Hexavalent chromate poses severe health hazards, including respiratory issues and skin sensitization, necessitating stringent handling protocols and personal protective equipment. Transitioning to trivalent chromate enhances workplace safety while maintaining corrosion resistance and durability of zinc-coated materials.

Performance and Durability on Zinc Substrates

Trivalent chromate coatings on zinc substrates offer superior environmental safety and comparable corrosion resistance to hexavalent chromate, making them a preferred choice for sustainable corrosion protection. Hexavalent chromate provides excellent performance and durability but is increasingly restricted due to its carcinogenic properties and environmental impact. Advances in trivalent chromate formulations have enhanced their adhesion, UV stability, and long-term durability, ensuring effective zinc substrate protection in industrial and automotive applications.

Cost Comparison: Trivalent vs Hexavalent Chromate

Trivalent chromate coatings typically incur higher initial costs than hexavalent chromate due to more complex production processes and specialized raw materials. However, trivalent chromate often results in reduced environmental compliance expenses and lower long-term liabilities tied to regulatory restrictions on hexavalent chromium. Evaluating total cost of ownership favors trivalent chromate for industries prioritizing sustainability and future-proofing against stringent environmental regulations.

Future Trends in Zinc Chromate Conversion Technologies

Future trends in zinc chromate conversion technologies emphasize the shift from hexavalent chromate, known for its high toxicity and environmental hazards, to trivalent chromate systems that offer enhanced corrosion resistance with significantly reduced health risks. Innovations in trivalent chromate formulations aim to improve coating adhesion, durability, and compatibility with various metal substrates while meeting increasingly strict regulatory standards. Advances in nanotechnology and green chemistry are driving the development of eco-friendly zinc chromate alternatives that maintain performance in aerospace, automotive, and industrial applications.

Trivalent Chromate vs Hexavalent Chromate Infographic

materialdif.com

materialdif.com