Zamak 3 and Zamak 5 are both zinc alloys commonly used in pet manufacturing due to their excellent strength and corrosion resistance. Zamak 3 offers a balanced composition with good mechanical properties and ease of casting, while Zamak 5 contains a higher copper content, enhancing its strength and fatigue resistance. Choosing between Zamak 3 and Zamak 5 depends on the specific durability requirements and environmental conditions of the pet product.

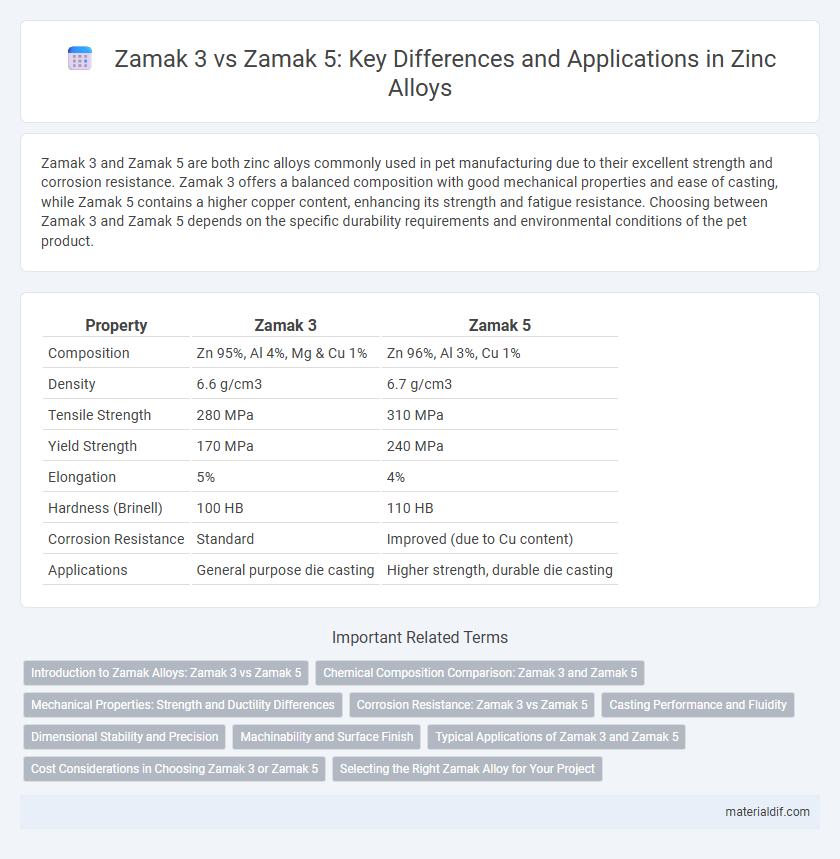

Table of Comparison

| Property | Zamak 3 | Zamak 5 |

|---|---|---|

| Composition | Zn 95%, Al 4%, Mg & Cu 1% | Zn 96%, Al 3%, Cu 1% |

| Density | 6.6 g/cm3 | 6.7 g/cm3 |

| Tensile Strength | 280 MPa | 310 MPa |

| Yield Strength | 170 MPa | 240 MPa |

| Elongation | 5% | 4% |

| Hardness (Brinell) | 100 HB | 110 HB |

| Corrosion Resistance | Standard | Improved (due to Cu content) |

| Applications | General purpose die casting | Higher strength, durable die casting |

Introduction to Zamak Alloys: Zamak 3 vs Zamak 5

Zamak 3 and Zamak 5 are popular zinc-aluminum alloys used extensively in die casting due to their excellent strength, corrosion resistance, and dimensional stability. Zamak 3 contains approximately 96% zinc, 4% aluminum, and minor amounts of copper and magnesium, delivering superior mechanical properties and good castability. In comparison, Zamak 5 has a slightly higher copper content, around 1%, enhancing its tensile strength and hardness, making it suitable for applications demanding greater durability and wear resistance.

Chemical Composition Comparison: Zamak 3 and Zamak 5

Zamak 3 primarily consists of 96% zinc, 4% aluminum, with trace amounts of magnesium and copper, providing excellent casting properties and corrosion resistance. Zamak 5 modifies this composition by increasing copper content to about 1%, enhancing strength and mechanical durability while maintaining similar zinc and aluminum levels. The higher copper in Zamak 5 makes it more suitable for applications demanding superior wear resistance compared to the more common Zamak 3 alloy.

Mechanical Properties: Strength and Ductility Differences

Zamak 3 exhibits higher strength due to its composition, typically offering tensile strength around 280 MPa, whereas Zamak 5 has a slightly lower tensile strength near 250 MPa but provides improved ductility and impact resistance. The increased aluminum content in Zamak 5 enhances its elongation, making it more suitable for applications requiring greater flexibility and deformation without failure. Mechanical property variations between the two alloys influence their selection depending on whether strength or ductility is prioritized in zinc die-casting projects.

Corrosion Resistance: Zamak 3 vs Zamak 5

Zamak 5 exhibits superior corrosion resistance compared to Zamak 3 due to its higher aluminum content, which enhances its protective oxide layer. Both alloys contain zinc, aluminum, magnesium, and copper; however, Zamak 5 typically includes about 1% copper, improving its durability in corrosive environments. This makes Zamak 5 more suitable for applications exposed to moisture and harsh conditions, while Zamak 3 remains adequate for less demanding uses.

Casting Performance and Fluidity

Zamak 3 offers superior casting performance and fluidity compared to Zamak 5 due to its lower melting point and optimized alloy composition, allowing for finer detail casting and shorter cycle times. The higher zinc content in Zamak 3 improves flow characteristics, reducing porosity and enhancing surface finish in intricate molds. While Zamak 5 contains more aluminum, providing increased strength, it slightly compromises fluidity and can lead to increased casting defects in complex geometries.

Dimensional Stability and Precision

Zamak 3 and Zamak 5 are zinc alloys commonly used in die casting, with Zamak 5 offering superior dimensional stability and precision due to its higher aluminum content, which enhances mechanical strength and reduces shrinkage during solidification. Zamak 3, while providing good castability, tends to experience more dimensional variability and lower resistance to deformation under stress compared to Zamak 5. For applications requiring tight tolerances and intricate details, Zamak 5 is the preferred choice, ensuring better consistency and accuracy in the final product.

Machinability and Surface Finish

Zamak 3 and Zamak 5 are popular zinc alloys with distinct differences in machinability and surface finish. Zamak 3 offers superior machinability due to its lower aluminum content, making it easier to achieve precise dimensions and intricate shapes. Zamak 5, containing higher aluminum levels, provides a smoother and more corrosion-resistant surface finish, ideal for decorative or high-quality applications.

Typical Applications of Zamak 3 and Zamak 5

Zamak 3 is widely used in die casting for automotive components, hardware fittings, and household appliances due to its excellent strength and dimensional stability. Zamak 5, with higher magnesium content, is preferred for applications requiring increased corrosion resistance and improved mechanical properties, such as electrical connectors and precision instruments. Both alloys are integral in manufacturing durable parts where cost-effective production and material reliability are essential.

Cost Considerations in Choosing Zamak 3 or Zamak 5

Zamak 3 generally offers a lower cost advantage compared to Zamak 5 due to its higher aluminum content and simpler alloy composition, making it a preferred choice for budget-sensitive applications. Zamak 5 includes additional copper, enhancing strength and corrosion resistance, which can increase material costs but reduce long-term maintenance expenses. Evaluating cost considerations involves balancing initial alloy price against durability requirements and potential lifecycle savings.

Selecting the Right Zamak Alloy for Your Project

Zamak 3 offers superior mechanical properties and corrosion resistance compared to Zamak 5, making it ideal for high-stress applications requiring durability. Zamak 5 contains higher aluminum content, enhancing its strength but reducing ductility, which is suitable for parts subject to moderate loads. Choosing the right Zamak alloy depends on balancing factors like strength, wear resistance, and cost efficiency for specific project requirements.

Zamak 3 vs Zamak 5 Infographic

materialdif.com

materialdif.com