Wrought zinc offers superior strength and flexibility compared to cast zinc, making it ideal for applications requiring durability and resistance to mechanical stress. Cast zinc, formed by pouring molten metal into molds, allows for intricate shapes and detailed designs but tends to be more brittle and less impact-resistant. Choosing between wrought and cast zinc depends on the specific structural and aesthetic requirements of the pet product.

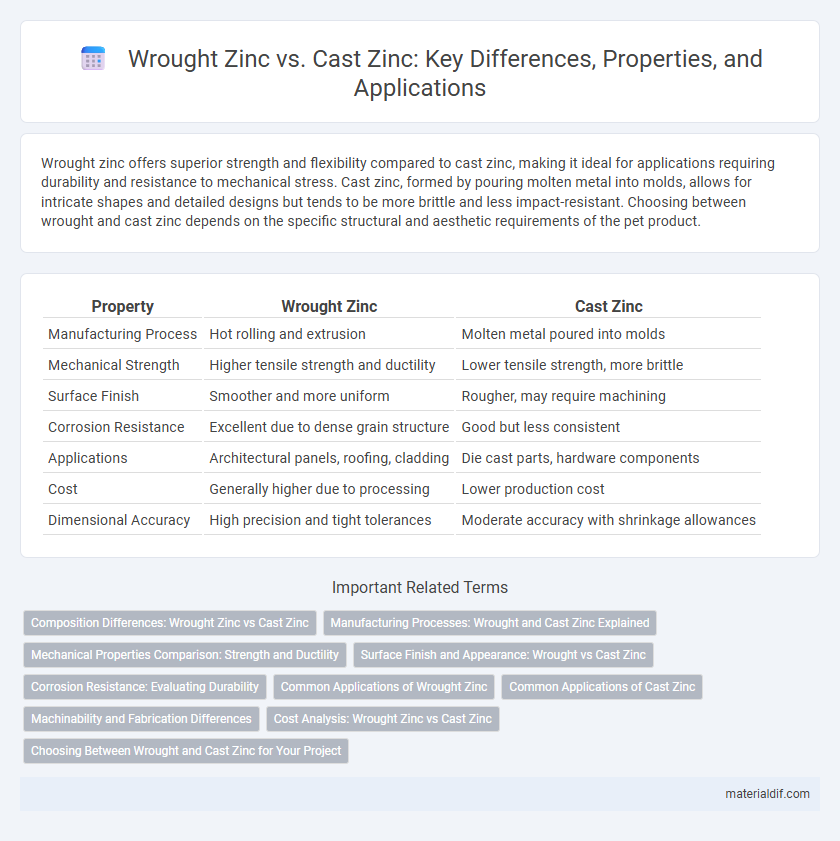

Table of Comparison

| Property | Wrought Zinc | Cast Zinc |

|---|---|---|

| Manufacturing Process | Hot rolling and extrusion | Molten metal poured into molds |

| Mechanical Strength | Higher tensile strength and ductility | Lower tensile strength, more brittle |

| Surface Finish | Smoother and more uniform | Rougher, may require machining |

| Corrosion Resistance | Excellent due to dense grain structure | Good but less consistent |

| Applications | Architectural panels, roofing, cladding | Die cast parts, hardware components |

| Cost | Generally higher due to processing | Lower production cost |

| Dimensional Accuracy | High precision and tight tolerances | Moderate accuracy with shrinkage allowances |

Composition Differences: Wrought Zinc vs Cast Zinc

Wrought zinc primarily consists of high-purity zinc with small amounts of aluminum, magnesium, and copper to enhance strength and ductility, while cast zinc contains higher levels of lead, iron, and other impurities for improved castability and cost-efficiency. The composition differences directly impact mechanical properties, with wrought zinc offering superior tensile strength and fatigue resistance compared to the more brittle cast zinc. These variations in alloying elements tailor wrought zinc for structural applications, whereas cast zinc suits intricate components requiring complex molds.

Manufacturing Processes: Wrought and Cast Zinc Explained

Wrought zinc is produced through mechanical deformation processes such as rolling, forging, or extrusion, resulting in improved ductility and strength due to the alignment of its grain structure. Cast zinc is created by melting the metal and pouring it into molds, allowing complex shapes but often leading to a more brittle microstructure with lower mechanical properties. These distinct manufacturing methods influence the final applications of wrought zinc in structural and architectural uses, while cast zinc is preferred for intricate components like die-cast parts and hardware.

Mechanical Properties Comparison: Strength and Ductility

Wrought zinc exhibits higher strength and improved ductility compared to cast zinc due to its refined grain structure achieved through mechanical working processes. The deformation during wrought processing aligns the metal's microstructure, enhancing tensile strength and resistance to cracking. In contrast, cast zinc typically has lower tensile strength and reduced ductility caused by its coarser grains and potential porosity formed during solidification.

Surface Finish and Appearance: Wrought vs Cast Zinc

Wrought zinc exhibits a smoother, more uniform surface finish due to its refined grain structure from rolling or extrusion processes, resulting in enhanced aesthetic appeal and better consistency in appearance. Cast zinc often presents a rougher surface with visible grain boundaries and potential porosity from the solidification process, which may require additional finishing treatments to achieve a comparable look. The choice between wrought and cast zinc impacts applications where surface aesthetics and finish quality are critical, such as architectural or decorative uses.

Corrosion Resistance: Evaluating Durability

Wrought zinc exhibits superior corrosion resistance compared to cast zinc due to its refined microstructure and fewer impurities, enhancing its durability in harsh environments. Cast zinc, with a coarser grain structure, is more prone to corrosion and wear over time, making it less suitable for long-term outdoor applications. Studies show that wrought zinc maintains protective oxide layers more effectively, extending the lifespan of metal components exposed to moisture and pollutants.

Common Applications of Wrought Zinc

Wrought zinc, known for its excellent malleability and corrosion resistance, is commonly used in architectural elements like roofing, gutters, and wall cladding. It is also prevalent in manufacturing decorative metalwork and alloy production, especially where precise shaping and durability are required. Compared to cast zinc, wrought zinc's superior mechanical properties make it ideal for applications involving forming and rolling processes.

Common Applications of Cast Zinc

Cast zinc is widely used in automotive components, electrical housings, and hardware due to its excellent castability and strength. It offers superior corrosion resistance and dimensional stability, making it ideal for complex shapes and intricate designs in consumer electronics and plumbing fixtures. Cast zinc alloys also play a significant role in die-casting industries for producing durable parts with high precision.

Machinability and Fabrication Differences

Wrought zinc offers superior machinability compared to cast zinc due to its refined microstructure and uniform grain size, enabling precise cutting and shaping with minimal tool wear. Cast zinc, while more brittle and prone to cracking during machining, excels in complex shapes through mold casting but requires slower feed rates and specialized tools to manage its lower ductility. Fabrication with wrought zinc allows for more versatile forming techniques such as rolling and forging, whereas cast zinc is primarily limited to foundry methods that tailor it for high-volume, detailed components with reduced post-processing.

Cost Analysis: Wrought Zinc vs Cast Zinc

Wrought zinc typically incurs higher production costs due to its labor-intensive manufacturing processes and superior material properties, resulting in increased durability and strength. Cast zinc offers a more cost-effective solution, benefiting from faster production cycles and lower material waste, which reduces overall expenses. Choosing between wrought zinc and cast zinc involves balancing upfront cost differences against long-term performance and maintenance savings.

Choosing Between Wrought and Cast Zinc for Your Project

Wrought zinc offers superior mechanical strength and flexibility, making it ideal for applications requiring durability and intricate shaping. Cast zinc excels in producing complex, heavy-duty components with excellent corrosion resistance and cost efficiency. Selecting between wrought and cast zinc depends on project requirements such as strength, detail, production volume, and budget constraints.

Wrought Zinc vs Cast Zinc Infographic

materialdif.com

materialdif.com