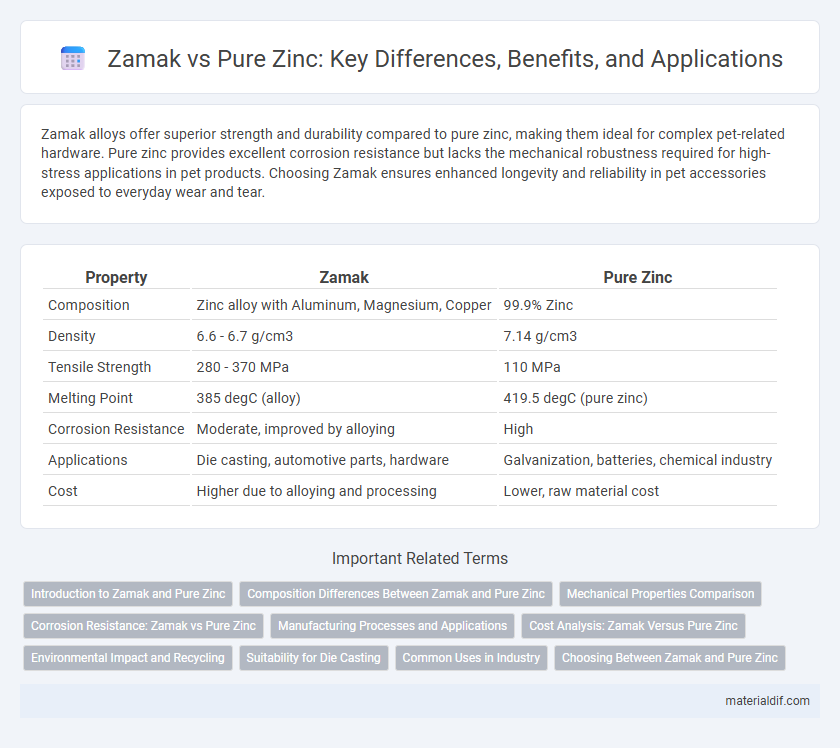

Zamak alloys offer superior strength and durability compared to pure zinc, making them ideal for complex pet-related hardware. Pure zinc provides excellent corrosion resistance but lacks the mechanical robustness required for high-stress applications in pet products. Choosing Zamak ensures enhanced longevity and reliability in pet accessories exposed to everyday wear and tear.

Table of Comparison

| Property | Zamak | Pure Zinc |

|---|---|---|

| Composition | Zinc alloy with Aluminum, Magnesium, Copper | 99.9% Zinc |

| Density | 6.6 - 6.7 g/cm3 | 7.14 g/cm3 |

| Tensile Strength | 280 - 370 MPa | 110 MPa |

| Melting Point | 385 degC (alloy) | 419.5 degC (pure zinc) |

| Corrosion Resistance | Moderate, improved by alloying | High |

| Applications | Die casting, automotive parts, hardware | Galvanization, batteries, chemical industry |

| Cost | Higher due to alloying and processing | Lower, raw material cost |

Introduction to Zamak and Pure Zinc

Zamak is a family of zinc alloys primarily composed of zinc with aluminum, magnesium, and copper, offering enhanced strength, corrosion resistance, and dimensional stability compared to pure zinc. Pure zinc, often used in galvanizing and die-casting, possesses excellent corrosion resistance and low melting point but lacks the mechanical robustness of zamak alloys. The unique alloy composition of zamak enables its widespread application in precision die-casting for automotive, hardware, and electronics industries.

Composition Differences Between Zamak and Pure Zinc

Zamak is an alloy primarily composed of zinc with approximately 4% aluminum, 1% magnesium, and trace amounts of copper, enhancing its strength and casting properties compared to pure zinc. Pure zinc consists of 99.9% zinc with minimal impurities, offering high corrosion resistance but lower mechanical strength. The addition of metals like aluminum in Zamak significantly improves its dimensional stability and durability in manufacturing processes.

Mechanical Properties Comparison

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, exhibit superior mechanical properties compared to pure zinc, including higher tensile strength typically around 280 MPa versus pure zinc's 120 MPa. The enhanced hardness and improved impact resistance of Zamak make it preferable for die-casting applications requiring durability and dimensional stability. Pure zinc's lower melting point and ductility limit its use in high-stress environments, whereas Zamak's alloy composition optimizes strength and wear resistance.

Corrosion Resistance: Zamak vs Pure Zinc

Zamak alloys exhibit superior corrosion resistance compared to pure zinc due to the inclusion of aluminum, magnesium, and copper, which enhance the alloy's protective oxide layer formation. Pure zinc provides natural corrosion resistance but is more susceptible to degradation in harsh environments without alloying elements. The corrosion performance of Zamak makes it ideal for applications requiring durability and longevity in exposure to moisture and chemicals.

Manufacturing Processes and Applications

Zamak, an alloy primarily composed of zinc with aluminum, magnesium, and copper, features enhanced strength and corrosion resistance compared to pure zinc, which is often used in galvanizing and die-casting due to its excellent malleability and low melting point. Manufacturing processes for zamak involve precise alloying and die casting to create durable components for automotive, hardware, and electronics industries, while pure zinc is commonly processed through hot-dip galvanizing and zinc electrolytic deposition to protect steel structures. The application differentiation is critical: zamak's robust mechanical properties suit load-bearing parts, whereas pure zinc's chemical purity benefits corrosion-resistant coatings and battery anodes.

Cost Analysis: Zamak Versus Pure Zinc

Zamak alloys generally offer lower production costs compared to pure zinc due to their improved casting properties and reduced material waste, enhancing manufacturing efficiency. Pure zinc, while offering higher corrosion resistance and purity, often incurs higher raw material expenses and processing costs. Evaluating the total cost impact involves considering alloy durability, machining requirements, and application-specific performance, often making Zamak a more cost-effective choice in mass production.

Environmental Impact and Recycling

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, offer improved recyclability compared to pure zinc due to their enhanced durability and corrosion resistance, leading to longer product life cycles and reduced resource consumption. Pure zinc, while fully recyclable, tends to have a higher environmental impact during extraction and refining processes, resulting in greater energy use and emissions. Recycling zamak reduces landfill waste and energy demand more effectively by maintaining the integrity of the alloy components, supporting sustainable manufacturing practices in industries like automotive and construction.

Suitability for Die Casting

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, are highly suitable for die casting due to their excellent fluidity, dimensional stability, and low melting point, which ensures faster production cycles and detailed mold replication. Pure zinc, while offering good corrosion resistance and toxicity safety, lacks the mechanical strength and fluidity required for high-precision die casting applications, often leading to increased wear on molds and less intricate castings. The optimized properties of Zamak make it the preferred choice in automotive, hardware, and consumer goods industries where high-quality die-cast parts are essential.

Common Uses in Industry

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, are widely used in die-casting for automotive parts, hardware, and electronics due to their strength, durability, and excellent casting properties. Pure zinc, known for its corrosion resistance and low melting point, is commonly utilized in galvanizing steel to prevent rust, as well as in battery production and chemical applications. Industrial reliance on zamak centers around complex, detailed components requiring high precision, while pure zinc serves critical roles where protective coatings and chemical stability are essential.

Choosing Between Zamak and Pure Zinc

Zamak alloys, composed mainly of zinc with aluminum, magnesium, and copper, offer superior strength and corrosion resistance compared to pure zinc, making them ideal for die casting applications requiring durability. Pure zinc, with its high malleability and excellent corrosion resistance, is better suited for applications needing flexibility and purity, such as galvanizing and architectural coatings. Selecting between Zamak and pure zinc depends on the specific mechanical properties and environmental performance required for a project.

Zamak vs Pure Zinc Infographic

materialdif.com

materialdif.com