Zinc casting involves pouring molten zinc into molds to create complex, detailed shapes with high dimensional accuracy, ideal for intricate zinc pet parts. Zinc stamping uses high-pressure presses to cut or form zinc sheets into specific shapes, offering faster production and lower costs for simpler, flat designs. Both methods provide strong, corrosion-resistant zinc pet components, but casting excels in customization while stamping is suited for mass production.

Table of Comparison

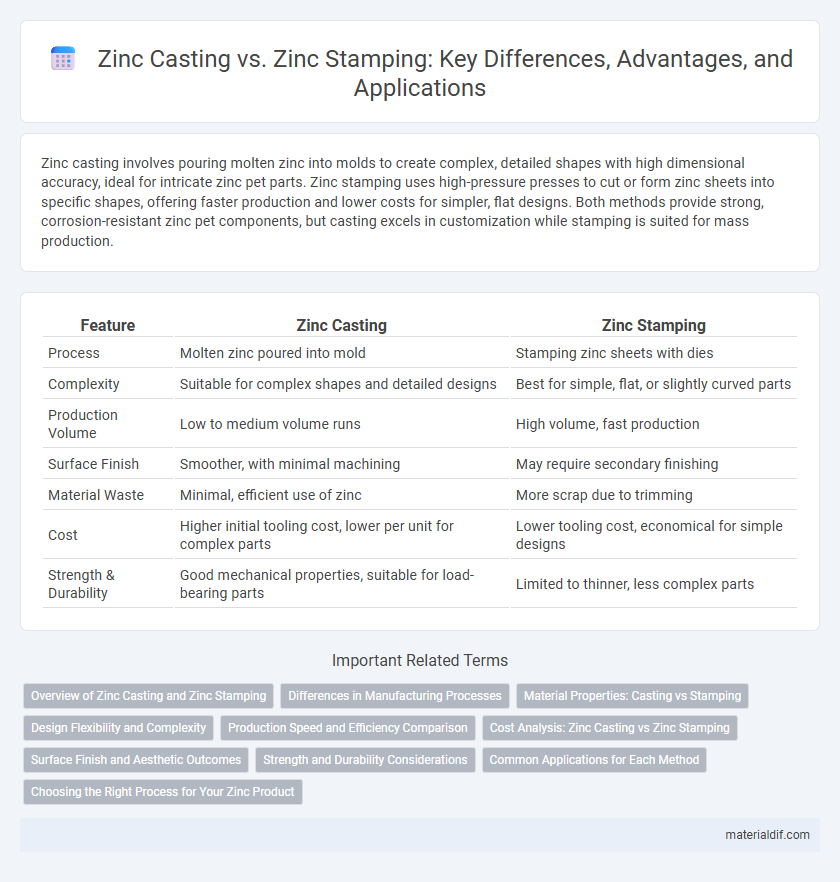

| Feature | Zinc Casting | Zinc Stamping |

|---|---|---|

| Process | Molten zinc poured into mold | Stamping zinc sheets with dies |

| Complexity | Suitable for complex shapes and detailed designs | Best for simple, flat, or slightly curved parts |

| Production Volume | Low to medium volume runs | High volume, fast production |

| Surface Finish | Smoother, with minimal machining | May require secondary finishing |

| Material Waste | Minimal, efficient use of zinc | More scrap due to trimming |

| Cost | Higher initial tooling cost, lower per unit for complex parts | Lower tooling cost, economical for simple designs |

| Strength & Durability | Good mechanical properties, suitable for load-bearing parts | Limited to thinner, less complex parts |

Overview of Zinc Casting and Zinc Stamping

Zinc casting involves pouring molten zinc into molds to create complex, durable shapes with excellent dimensional accuracy, suitable for intricate designs and heavy-duty components. Zinc stamping entails cutting and shaping zinc sheets under high pressure, producing lightweight, uniform parts ideal for high-volume manufacturing and thin-walled products. Both methods leverage zinc's corrosion resistance and malleability, with casting favored for complex geometries and stamping preferred for speed and cost efficiency in mass production.

Differences in Manufacturing Processes

Zinc casting involves pouring molten zinc into molds to create complex shapes with high precision and smooth finishes, ideal for detailed, three-dimensional components. Zinc stamping uses high-pressure mechanical presses to shape zinc sheets into desired forms, offering faster production rates suited for simpler, flat or slightly curved parts. The casting process allows for greater design flexibility and structural integrity, while stamping is more cost-effective for high-volume, less intricate pieces.

Material Properties: Casting vs Stamping

Zinc casting enables complex geometries and thicker sections due to its molten state, resulting in superior dimensional stability and uniform strength throughout the part. Zinc stamping, using cold or hot sheets, offers high production speed and consistent surface finish but is limited in thickness and three-dimensional shapes, often leading to work hardening and potential stress concentration points. The casting process exploits zinc's fluidity and lower melting point to produce durable components with enhanced mechanical properties, while stamping focuses on efficiency and cost-effectiveness for simpler designs.

Design Flexibility and Complexity

Zinc casting offers superior design flexibility and complexity, allowing for intricate shapes and detailed geometries that are difficult to achieve with stamping. The casting process accommodates undercuts, varying wall thicknesses, and complex internal features, enabling customized and high-precision components. In contrast, zinc stamping is limited to simpler, flat or moderately bent designs due to the constraints of metal deformation and tooling.

Production Speed and Efficiency Comparison

Zinc casting offers slower production speeds due to the cooling and solidification process but excels in creating complex geometries with high dimensional accuracy. Zinc stamping enables rapid production cycles, making it highly efficient for large-volume runs of simpler components with consistent thickness. Efficiency in zinc stamping is enhanced by minimal post-processing, whereas zinc casting may require additional machining, impacting overall throughput.

Cost Analysis: Zinc Casting vs Zinc Stamping

Zinc stamping generally offers lower production costs due to faster cycle times and reduced material waste compared to zinc casting, which involves higher expenses related to mold creation and longer curing periods. The initial tooling investment for zinc casting is typically higher, but it allows for greater design complexity and dimensional accuracy, potentially justifying the cost in specialized applications. Overall, zinc stamping is more cost-effective for high-volume, simple-shape components, while zinc casting is preferred when precision and intricate details outweigh initial expenditures.

Surface Finish and Aesthetic Outcomes

Zinc casting produces complex shapes with smooth, detailed surface finishes ideal for decorative and high-aesthetic applications, offering uniform texture and enhanced durability. Zinc stamping delivers crisp outlines and consistent surface patterns but may lack the refined finish achievable through casting, often requiring additional surface treatments. Surface finish quality in zinc casting surpasses stamping by providing superior depth, clarity, and fewer imperfections, critical for premium visual appeal.

Strength and Durability Considerations

Zinc casting produces parts with superior strength and durability due to its ability to form complex, dense microstructures that resist wear and mechanical stress. Zinc stamping, while efficient and cost-effective for high-volume production, results in thinner, less robust components that may deform under heavy loads. Selecting zinc casting ensures enhanced structural integrity for applications requiring long-term reliability and resistance to impact.

Common Applications for Each Method

Zinc casting is commonly used for complex components in automotive, hardware, and electronic enclosures due to its ability to produce intricate shapes with high strength. Zinc stamping is preferred for manufacturing flat, thin parts such as connectors, terminals, and decorative trims where precision and speed are essential. Both methods serve distinct industries, with casting excelling in detailed, durable parts and stamping catering to high-volume, lightweight components.

Choosing the Right Process for Your Zinc Product

Selecting the appropriate method for zinc product manufacturing hinges on the desired complexity and volume of the final item. Zinc casting delivers intricate geometries and superior strength, ideal for detailed components requiring high durability, while zinc stamping offers cost-effective, high-speed production suited for simpler shapes and large batches. Evaluating factors like production scale, design intricacy, and mechanical properties ensures optimal process choice for zinc-based products.

Zinc Casting vs Zinc Stamping Infographic

materialdif.com

materialdif.com