Galvanizing involves coating steel with a thick layer of zinc through a hot-dip process, providing superior corrosion resistance and durability ideal for outdoor applications. Zinc plating applies a thinner zinc layer using electroplating, offering a smoother finish suited for indoor use where minimal exposure to moisture occurs. Choosing between galvanizing and zinc plating depends on environmental factors and the level of protection required for the metal.

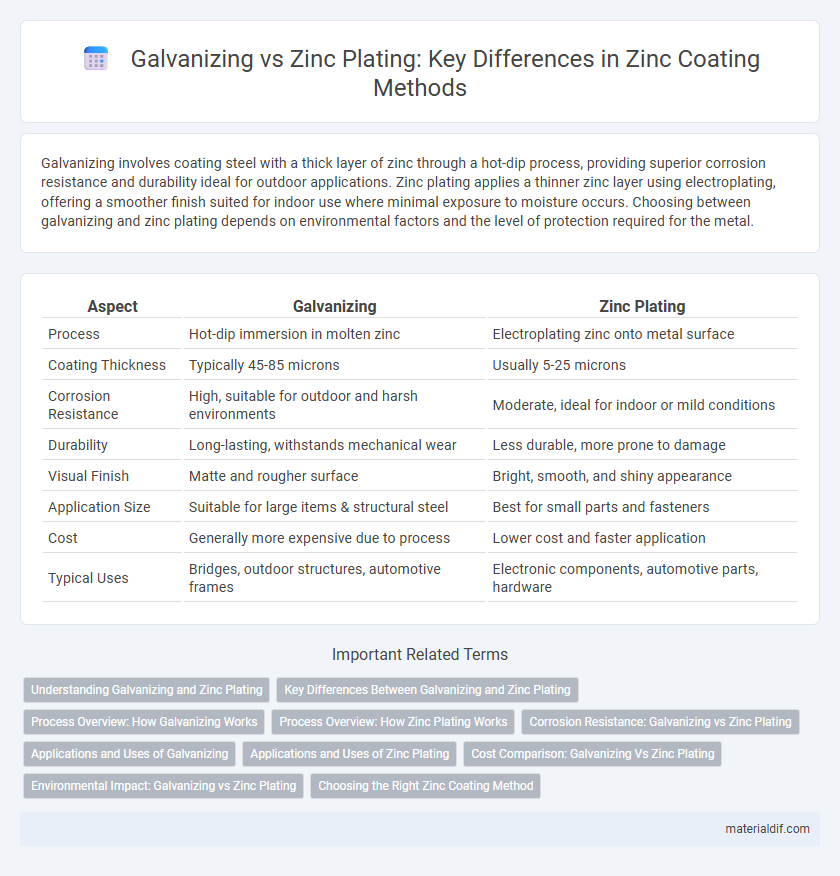

Table of Comparison

| Aspect | Galvanizing | Zinc Plating |

|---|---|---|

| Process | Hot-dip immersion in molten zinc | Electroplating zinc onto metal surface |

| Coating Thickness | Typically 45-85 microns | Usually 5-25 microns |

| Corrosion Resistance | High, suitable for outdoor and harsh environments | Moderate, ideal for indoor or mild conditions |

| Durability | Long-lasting, withstands mechanical wear | Less durable, more prone to damage |

| Visual Finish | Matte and rougher surface | Bright, smooth, and shiny appearance |

| Application Size | Suitable for large items & structural steel | Best for small parts and fasteners |

| Cost | Generally more expensive due to process | Lower cost and faster application |

| Typical Uses | Bridges, outdoor structures, automotive frames | Electronic components, automotive parts, hardware |

Understanding Galvanizing and Zinc Plating

Galvanizing involves applying a thick, durable zinc coating to steel or iron through a hot-dip process, providing superior corrosion resistance in outdoor or industrial environments. Zinc plating, typically a thinner electroplated layer, offers aesthetic appeal and moderate protection mainly for indoor use or components with limited exposure to harsh conditions. Understanding the differences in coating thickness, corrosion protection, and application methods is crucial for selecting the proper zinc treatment for metal durability and longevity.

Key Differences Between Galvanizing and Zinc Plating

Galvanizing involves coating steel or iron with a thick layer of zinc through a hot-dip process, providing superior corrosion resistance and durability in harsh environments. Zinc plating applies a thin zinc layer via electroplating, offering aesthetic appeal and moderate protection primarily for indoor or less demanding applications. The key differences lie in coating thickness, application methods, corrosion resistance levels, and suitability for different environmental conditions.

Process Overview: How Galvanizing Works

Galvanizing involves coating steel or iron with a protective layer of molten zinc through a hot-dip process that creates a strong metallurgical bond, enhancing corrosion resistance. The metal is first cleaned and fluxed to remove impurities before immersion in a zinc bath typically heated to around 450degC (842degF). This process forms multiple zinc-iron alloy layers, providing a durable and long-lasting shield against environmental damage.

Process Overview: How Zinc Plating Works

Zinc plating involves electroplating a thin layer of zinc onto a metal surface to provide corrosion resistance and a decorative finish. The process starts with cleaning the metal substrate, followed by immersion in an electrolyte solution containing zinc ions, where an electrical current causes zinc to deposit evenly. This method offers precise control over coating thickness, suitable for small components requiring enhanced durability and aesthetic appeal.

Corrosion Resistance: Galvanizing vs Zinc Plating

Galvanizing provides superior corrosion resistance by forming a thick, durable zinc coating that protects steel from rust through sacrificial oxidation, even when scratched. Zinc plating offers a thinner layer of zinc which is less effective in harsh environments and typically requires additional protective coatings to prevent corrosion. For long-term protection in outdoor or industrial settings, galvanizing outperforms zinc plating in resisting corrosion and extending the lifespan of steel structures.

Applications and Uses of Galvanizing

Galvanizing is primarily used to protect steel structures in construction, automotive, and heavy machinery industries due to its thick, durable zinc coating that prevents corrosion over long periods. This method is ideal for outdoor applications such as bridges, guard rails, and utility poles where exposure to harsh weather conditions is common. Compared to zinc plating, galvanizing offers superior protection for large-scale and structural components requiring enhanced corrosion resistance and extended service life.

Applications and Uses of Zinc Plating

Zinc plating is widely used for corrosion protection and decorative purposes on small metal components, such as fasteners, automotive parts, and household appliances, due to its thin, uniform coating that enhances appearance and resists rust. Unlike galvanizing, which applies a thick zinc layer ideal for heavy-duty outdoor structures like steel frameworks and bridges, zinc plating suits applications requiring precise, lightweight coatings with excellent adhesion. The versatility of zinc plating enables its use in electronics, hardware, and machinery parts that demand both aesthetic value and surface durability.

Cost Comparison: Galvanizing Vs Zinc Plating

Galvanizing typically incurs higher initial costs compared to zinc plating due to the thicker zinc coating and more intensive process involved. However, galvanizing offers superior long-term corrosion protection, potentially reducing maintenance expenses and replacement frequency. Zinc plating is more cost-effective for small, intricate parts requiring thinner coatings but may lead to higher lifecycle costs in harsh environments.

Environmental Impact: Galvanizing vs Zinc Plating

Galvanizing produces a thicker zinc coating that offers superior corrosion resistance and longer lifespan, reducing the frequency of replacements and waste generation. Zinc plating involves thinner layers and typically requires chemical treatments that can release hazardous substances, increasing environmental concerns. Overall, hot-dip galvanizing presents a more sustainable option with lower environmental impact due to its durability and less toxic processing methods.

Choosing the Right Zinc Coating Method

Selecting the appropriate zinc coating method depends on the desired corrosion resistance and application environment. Galvanizing offers a thicker zinc layer, providing superior protection for outdoor and industrial uses, while zinc plating is ideal for indoor, decorative, or precision components requiring a thinner coating. Cost-effectiveness and durability requirements should guide the choice between hot-dip galvanizing and electroplated zinc coatings.

Galvanizing vs Zinc Plating Infographic

materialdif.com

materialdif.com