Zinc coating provides a uniform, corrosion-resistant layer on metal surfaces through electroplating or hot-dip methods, ensuring long-lasting protection. Zinc spraying, also known as metallizing, involves spraying molten or heated zinc particles onto surfaces, offering flexible application on complex shapes and repair areas. Both methods enhance durability in zinc pet products, with coating favored for smoother finishes and spraying chosen for custom or maintenance needs.

Table of Comparison

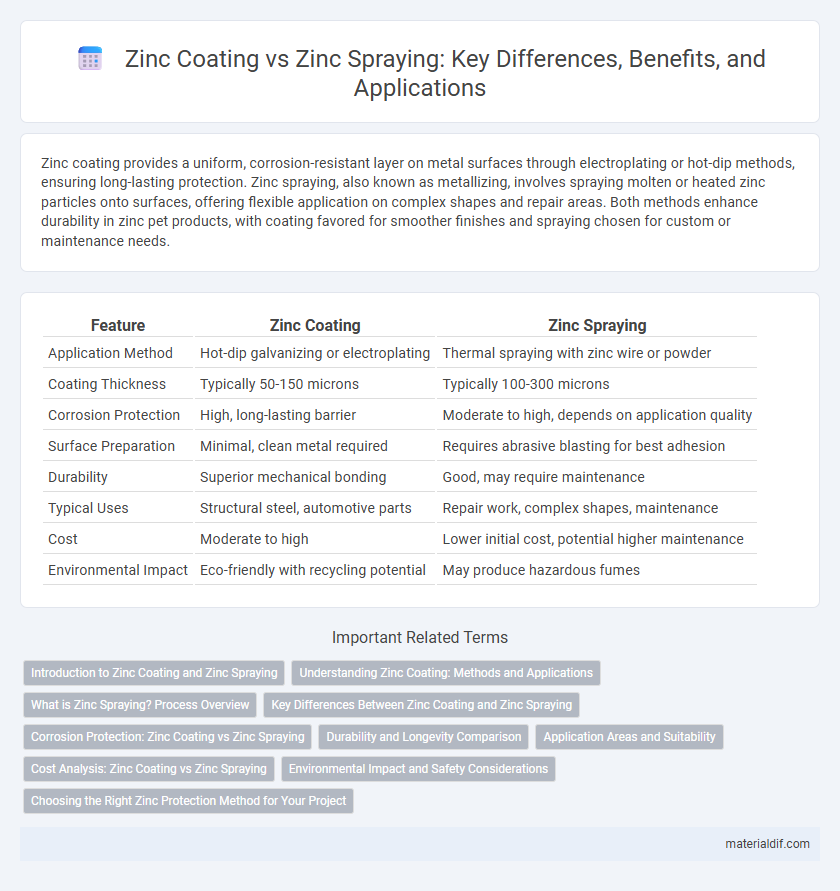

| Feature | Zinc Coating | Zinc Spraying |

|---|---|---|

| Application Method | Hot-dip galvanizing or electroplating | Thermal spraying with zinc wire or powder |

| Coating Thickness | Typically 50-150 microns | Typically 100-300 microns |

| Corrosion Protection | High, long-lasting barrier | Moderate to high, depends on application quality |

| Surface Preparation | Minimal, clean metal required | Requires abrasive blasting for best adhesion |

| Durability | Superior mechanical bonding | Good, may require maintenance |

| Typical Uses | Structural steel, automotive parts | Repair work, complex shapes, maintenance |

| Cost | Moderate to high | Lower initial cost, potential higher maintenance |

| Environmental Impact | Eco-friendly with recycling potential | May produce hazardous fumes |

Introduction to Zinc Coating and Zinc Spraying

Zinc coating involves applying a layer of zinc to metal surfaces through methods like hot-dip galvanizing, providing durable corrosion resistance. Zinc spraying, also known as metallizing, uses thermal spray techniques to deposit molten zinc particles onto substrates, offering a versatile protective finish suitable for complex shapes. Both methods enhance metal longevity by forming protective barriers against rust and environmental damage, with zinc coating typically used for mass-produced items and zinc spraying favored for repair or on-site applications.

Understanding Zinc Coating: Methods and Applications

Zinc coating involves applying a protective layer of zinc to steel or iron surfaces through methods like hot-dip galvanizing, electroplating, or zinc spraying, offering corrosion resistance by forming a barrier and sacrificial protection. Hot-dip galvanizing is the most common method, where the metal is submerged in molten zinc, creating a thick, durable coating ideal for structural steel and outdoor applications. Zinc spraying, a thermal spray process, produces a thinner but flexible coating suitable for maintenance and repair work on existing galvanized surfaces.

What is Zinc Spraying? Process Overview

Zinc spraying, also known as metallizing, involves the application of molten zinc onto a surface using a spray gun to provide corrosion protection. The process includes cleaning the substrate, melting zinc wire or powder, and atomizing the molten zinc onto the surface, creating a uniform protective layer. This method is preferred for coating large structures or irregular shapes where traditional zinc coating techniques may be impractical.

Key Differences Between Zinc Coating and Zinc Spraying

Zinc coating involves the application of molten zinc onto steel through hot-dip galvanizing, creating a thick, durable layer that provides long-term corrosion resistance. Zinc spraying, also known as metallizing, uses a thermal spray gun to project molten zinc onto surfaces, resulting in a thinner, more flexible coating ideal for repairing or protecting irregular shapes. Key differences include the thickness and durability of the coating, application methods, and suitability for different surface geometries and repair needs.

Corrosion Protection: Zinc Coating vs Zinc Spraying

Zinc coating provides a thick, uniform layer that offers superior long-term corrosion protection by forming a stable barrier against moisture and oxygen. Zinc spraying, also known as metallizing, creates a mechanically bonded zinc layer that offers effective but thinner corrosion resistance, ideal for repairs and complex surfaces. The choice between zinc coating and zinc spraying depends on the required durability and application environment, with coatings generally outperforming sprays in heavy-duty corrosion scenarios.

Durability and Longevity Comparison

Zinc coating provides superior durability through a thicker, more uniform layer that offers long-lasting protection against corrosion, often lasting 20 to 50 years depending on environmental exposure. Zinc spraying creates a thinner, less consistent barrier that may require more frequent maintenance, typically protecting surfaces for 5 to 15 years in similar conditions. The longevity of zinc coating generally surpasses zinc spraying, making it a preferred choice for heavy-duty, corrosion-resistant applications.

Application Areas and Suitability

Zinc coating is commonly applied in industrial manufacturing for corrosion resistance on steel structures, automotive parts, and construction materials, offering long-term protection in harsh environments. Zinc spraying provides a versatile solution for maintenance and repair of large or irregularly shaped surfaces, such as bridges, pipelines, and marine vessels, ensuring localized protection where traditional coatings are impractical. Both methods enhance durability but differ in application flexibility and suitability based on the size, shape, and environmental exposure of the substrate.

Cost Analysis: Zinc Coating vs Zinc Spraying

Zinc coating generally involves a hot-dip galvanizing process that offers durable protection at a higher upfront cost, typically ranging from $1.50 to $3.00 per square foot, depending on thickness and application complexity. Zinc spraying, or metallizing, usually has lower initial costs between $0.75 and $1.50 per square foot but may require more frequent maintenance and reapplication due to thinner coatings. Evaluating total lifecycle expenses, including application, maintenance, and longevity, zinc coating often proves more cost-effective for heavy-duty corrosion protection.

Environmental Impact and Safety Considerations

Zinc coating, typically applied through hot-dip galvanizing, creates a durable, corrosion-resistant layer that minimizes the need for frequent maintenance and reduces metal waste, making it environmentally sustainable over time. Zinc spraying involves molten zinc particles sprayed onto surfaces, producing a thinner protective layer but requiring proper ventilation and protective gear to mitigate inhalation of zinc fumes and particulate matter, ensuring worker safety. Both methods reduce steel corrosion and extend lifespan, but zinc coating offers longer-lasting protection with lower environmental emissions, while zinc spraying demands stricter safety protocols during application.

Choosing the Right Zinc Protection Method for Your Project

Zinc coating offers a durable, long-lasting barrier against corrosion, ideal for heavy-duty structural steel exposed to harsh environments, while zinc spraying provides a flexible, cost-effective solution for repair work and complex geometries. Selecting between these methods depends on factors such as substrate condition, environmental exposure, project scale, and budget constraints. Evaluating the required corrosion resistance and application feasibility ensures optimal zinc protection tailored to your project's specific needs.

Zinc Coating vs Zinc Spraying Infographic

materialdif.com

materialdif.com