Zinc phosphate coating provides excellent corrosion resistance and improved paint adhesion, making it ideal for automotive and heavy-duty applications. Chromate conversion coating enhances metal surfaces by offering superior corrosion protection and electrical conductivity, commonly used in aerospace and electronics. Choosing between zinc phosphate and chromate conversion coatings depends on the specific environmental exposure and performance requirements of the metal component.

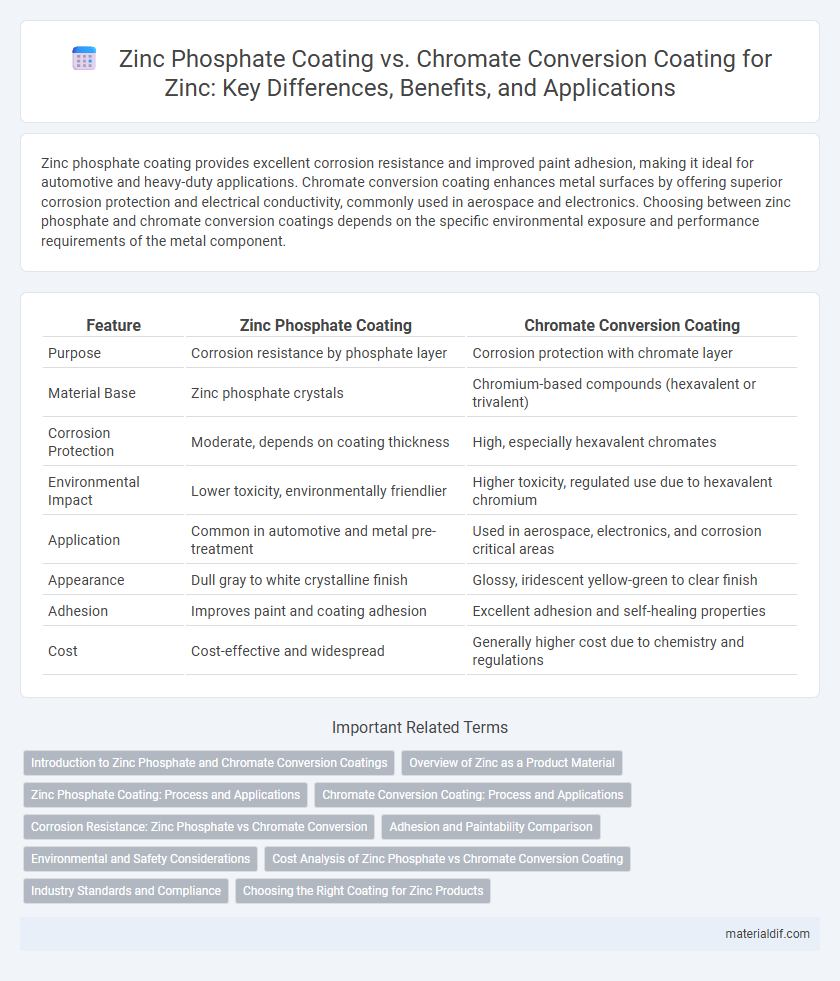

Table of Comparison

| Feature | Zinc Phosphate Coating | Chromate Conversion Coating |

|---|---|---|

| Purpose | Corrosion resistance by phosphate layer | Corrosion protection with chromate layer |

| Material Base | Zinc phosphate crystals | Chromium-based compounds (hexavalent or trivalent) |

| Corrosion Protection | Moderate, depends on coating thickness | High, especially hexavalent chromates |

| Environmental Impact | Lower toxicity, environmentally friendlier | Higher toxicity, regulated use due to hexavalent chromium |

| Application | Common in automotive and metal pre-treatment | Used in aerospace, electronics, and corrosion critical areas |

| Appearance | Dull gray to white crystalline finish | Glossy, iridescent yellow-green to clear finish |

| Adhesion | Improves paint and coating adhesion | Excellent adhesion and self-healing properties |

| Cost | Cost-effective and widespread | Generally higher cost due to chemistry and regulations |

Introduction to Zinc Phosphate and Chromate Conversion Coatings

Zinc phosphate coatings form a crystalline layer of zinc phosphate on metal surfaces, providing excellent corrosion resistance and paint adhesion, commonly used in automotive and industrial applications. Chromate conversion coatings create a chemical conversion layer on metals like aluminum and zinc, offering corrosion protection and enhancing paint bonding through a self-healing effect. Both coatings improve metal durability but differ in composition, environmental impact, and specific industrial uses.

Overview of Zinc as a Product Material

Zinc serves as a critical component in both zinc phosphate and chromate conversion coatings, providing excellent corrosion resistance and surface adhesion. Zinc phosphate coatings offer superior paint adhesion and improved corrosion protection by forming a crystalline phosphate layer, while chromate conversion coatings create a thin, self-healing protective film primarily used for aluminum, zinc, and its alloys. Both coatings leverage zinc's anti-corrosive properties but differ in chemical composition and specific industrial applications.

Zinc Phosphate Coating: Process and Applications

Zinc phosphate coating is a chemical conversion process that deposits a crystalline phosphate layer on metal surfaces, enhancing corrosion resistance and paint adhesion. Commonly applied in the automotive, appliance, and construction industries, this coating improves durability and extends the lifespan of steel components. Unlike chromate conversion coatings, zinc phosphate is less toxic and offers excellent compatibility with subsequent painting and powder coating processes.

Chromate Conversion Coating: Process and Applications

Chromate conversion coating involves chemically treating zinc surfaces with a solution containing chromate ions to form a protective, corrosion-resistant layer. This process enhances adhesion for subsequent coatings and improves durability, making it ideal for automotive parts, aerospace components, and electronics. Its ability to provide excellent corrosion protection without adding significant weight or thickness boosts the lifespan of zinc-coated products.

Corrosion Resistance: Zinc Phosphate vs Chromate Conversion

Zinc phosphate coatings provide a robust base layer that significantly enhances corrosion resistance by forming a crystalline phosphate structure that facilitates paint adhesion and prevents rust formation. Chromate conversion coatings offer superior corrosion protection by creating a passive layer rich in hexavalent chromium compounds, which effectively inhibit oxidation and self-heal minor surface damages. Compared to zinc phosphate, chromate conversion coatings deliver longer-lasting corrosion resistance, especially in harsh environments, making them ideal for critical aerospace and automotive applications.

Adhesion and Paintability Comparison

Zinc phosphate coating offers superior adhesion and paintability compared to chromate conversion coating due to its crystalline phosphate layer, which enhances mechanical bonding and provides excellent paint receptivity. Chromate conversion coatings, while providing corrosion resistance, often result in weaker adhesion and prone to paint delamination under stress. Zinc phosphate's enhanced surface roughness and chemical bonding properties significantly improve paint durability and overall coating performance in industrial applications.

Environmental and Safety Considerations

Zinc phosphate coating provides an environmentally safer alternative to chromate conversion coating by avoiding toxic hexavalent chromium compounds, which are carcinogenic and highly regulated. It uses non-toxic phosphate chemicals that reduce hazardous waste disposal concerns and improve workplace safety. The adoption of zinc phosphate coatings supports compliance with stringent environmental regulations like RoHS and REACH while maintaining corrosion resistance.

Cost Analysis of Zinc Phosphate vs Chromate Conversion Coating

Zinc phosphate coating generally offers a lower upfront cost compared to chromate conversion coating due to simpler application processes and less expensive chemicals. While chromate conversion coatings provide superior corrosion resistance and longer service life, their higher environmental compliance expenses and toxic waste handling increase overall costs. Evaluating total cost of ownership reveals zinc phosphate as a cost-effective choice for applications with moderate corrosion protection requirements.

Industry Standards and Compliance

Zinc phosphate coating meets industry standards such as ASTM B767 and is widely used for corrosion resistance and paint adhesion in automotive and aerospace sectors, complying with RoHS regulations for environmental safety. Chromate conversion coating adheres to MIL-DTL-5541 and ASTM B633 standards, offering superior corrosion protection and conductivity, essential for military and electronic applications. Both coatings must comply with REACH regulations, but chromate coatings often face stricter restrictions due to hexavalent chromium content.

Choosing the Right Coating for Zinc Products

Zinc phosphate coating provides superior corrosion resistance and excellent paint adhesion, making it ideal for automotive and industrial applications requiring durable finishes. Chromate conversion coating offers enhanced corrosion protection with a thinner, environmentally friendly layer that improves conductivity and adhesion on zinc surfaces. Selecting the right coating depends on specific requirements such as corrosion resistance, environmental impact, and application methods for zinc products.

Zinc Phosphate Coating vs Chromate Conversion Coating Infographic

materialdif.com

materialdif.com