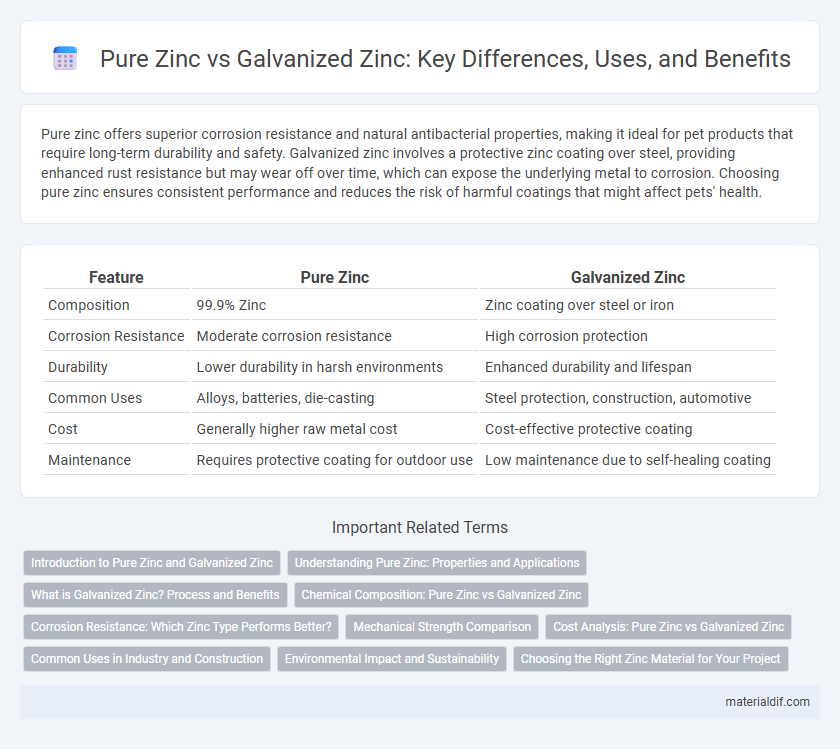

Pure zinc offers superior corrosion resistance and natural antibacterial properties, making it ideal for pet products that require long-term durability and safety. Galvanized zinc involves a protective zinc coating over steel, providing enhanced rust resistance but may wear off over time, which can expose the underlying metal to corrosion. Choosing pure zinc ensures consistent performance and reduces the risk of harmful coatings that might affect pets' health.

Table of Comparison

| Feature | Pure Zinc | Galvanized Zinc |

|---|---|---|

| Composition | 99.9% Zinc | Zinc coating over steel or iron |

| Corrosion Resistance | Moderate corrosion resistance | High corrosion protection |

| Durability | Lower durability in harsh environments | Enhanced durability and lifespan |

| Common Uses | Alloys, batteries, die-casting | Steel protection, construction, automotive |

| Cost | Generally higher raw metal cost | Cost-effective protective coating |

| Maintenance | Requires protective coating for outdoor use | Low maintenance due to self-healing coating |

Introduction to Pure Zinc and Galvanized Zinc

Pure zinc is a naturally occurring metal known for its high corrosion resistance and is primarily used in die-casting, batteries, and alloys. Galvanized zinc refers to steel or iron coated with a layer of zinc through a hot-dip process to prevent rust and improve durability. The zinc coating in galvanized materials acts as a sacrificial anode, offering long-lasting protection against environmental degradation.

Understanding Pure Zinc: Properties and Applications

Pure zinc exhibits excellent corrosion resistance, moderate strength, and good electrical conductivity, making it ideal for batteries, die-casting, and corrosion protection. Its malleability and low melting point facilitate easy casting and shaping in various industrial processes. Unlike galvanized zinc coatings, which are zinc layers applied over steel, pure zinc is used in applications where its inherent chemical and physical properties are directly required.

What is Galvanized Zinc? Process and Benefits

Galvanized zinc is zinc-coated steel, achieved through a hot-dip galvanization process where steel is immersed in molten zinc, forming a protective barrier against corrosion. This coating enhances durability, prevents rust, and significantly prolongs the lifespan of steel structures in harsh environments. The process creates a strong metallurgical bond that provides sacrificial protection, meaning the zinc corrodes first, safeguarding the underlying steel.

Chemical Composition: Pure Zinc vs Galvanized Zinc

Pure zinc consists almost entirely of elemental zinc with minimal impurities, resulting in a chemical composition exceeding 99.9% zinc. Galvanized zinc refers to a zinc coating applied over steel or iron, typically containing small amounts of iron and trace elements due to the galvanization process. The chemical composition of galvanized zinc varies but generally includes zinc alloys designed to enhance corrosion resistance and adhesion.

Corrosion Resistance: Which Zinc Type Performs Better?

Pure zinc offers inherent corrosion resistance due to its stable oxide layer, but galvanized zinc provides superior protection by coating steel with a thicker zinc layer that acts as a sacrificial anode, preventing rust effectively. Galvanized zinc's performance excels in harsh environments where steel substrates require long-lasting corrosion prevention, outperforming pure zinc alone. The galvanization process enhances zinc's protective qualities, making it preferred for industrial applications demanding robust corrosion resistance.

Mechanical Strength Comparison

Pure zinc exhibits lower mechanical strength with a tensile strength typically around 100 MPa, making it less suitable for structural applications. Galvanized zinc, often referring to zinc coatings on steel, benefits from the underlying steel's high tensile strength, usually exceeding 400 MPa, providing enhanced durability and resistance to mechanical stress. The galvanization process combines corrosion resistance of zinc with the superior mechanical properties of steel, leading to a more robust material profile.

Cost Analysis: Pure Zinc vs Galvanized Zinc

Pure zinc typically involves higher material costs due to its refined composition and limited industrial applications, whereas galvanized zinc, consisting of a zinc coating on steel or iron, offers a cost-effective corrosion protection solution for construction and manufacturing industries. The galvanization process adds an economical protective layer, significantly extending the lifespan of metal structures and reducing maintenance expenses, thereby lowering the total cost of ownership compared to using pure zinc components. Cost analysis often favors galvanized zinc because it balances affordability with durability, making it the preferred choice for large-scale applications requiring rust resistance.

Common Uses in Industry and Construction

Pure zinc is widely used in die casting, battery production, and the manufacturing of zinc oxide for rubber and pharmaceutical industries due to its excellent corrosion resistance and conductivity. Galvanized zinc, which involves coating steel or iron with a zinc layer, is primarily employed in construction for roofing, structural frameworks, and outdoor infrastructure to prevent rust and extend material lifespan. Industrial applications favor pure zinc for chemical and electrical uses, while construction relies heavily on galvanized zinc for durable protection against environmental damage.

Environmental Impact and Sustainability

Pure zinc offers a significantly lower environmental impact compared to galvanized zinc, as it avoids the use of additional coatings and alloys that can complicate recycling and waste management. Galvanized zinc, coated with a layer of zinc to protect steel from corrosion, often involves the release of hazardous substances during manufacturing and disposal, posing sustainability challenges. Using pure zinc facilitates a more sustainable lifecycle due to its higher recyclability and reduced chemical toxicity.

Choosing the Right Zinc Material for Your Project

Pure zinc offers excellent corrosion resistance and is ideal for applications requiring long-term durability without coating, while galvanized zinc features a protective zinc coating over steel or iron, enhancing rust prevention in structural projects. Selecting the right zinc material depends on environmental exposure, budget, and mechanical needs; galvanized zinc suits outdoor and industrial uses due to its robust defense against oxidation. Understanding project requirements ensures optimal performance, with pure zinc preferred for chemical stability and galvanized zinc favored for structural reinforcement and cost-effectiveness.

Pure Zinc vs Galvanized Zinc Infographic

materialdif.com

materialdif.com