Zinc-rich primers provide superior corrosion resistance by delivering high levels of metallic zinc, which serves as a sacrificial anode to protect steel surfaces. Zinc silicate primers combine zinc particles with silicate binders, offering enhanced durability and weather resistance while maintaining excellent protective properties. Choosing between the two depends on the operating environment, where zinc-rich primers excel in marine or industrial settings, and zinc silicate primers perform well under moderate conditions requiring long-term protection.

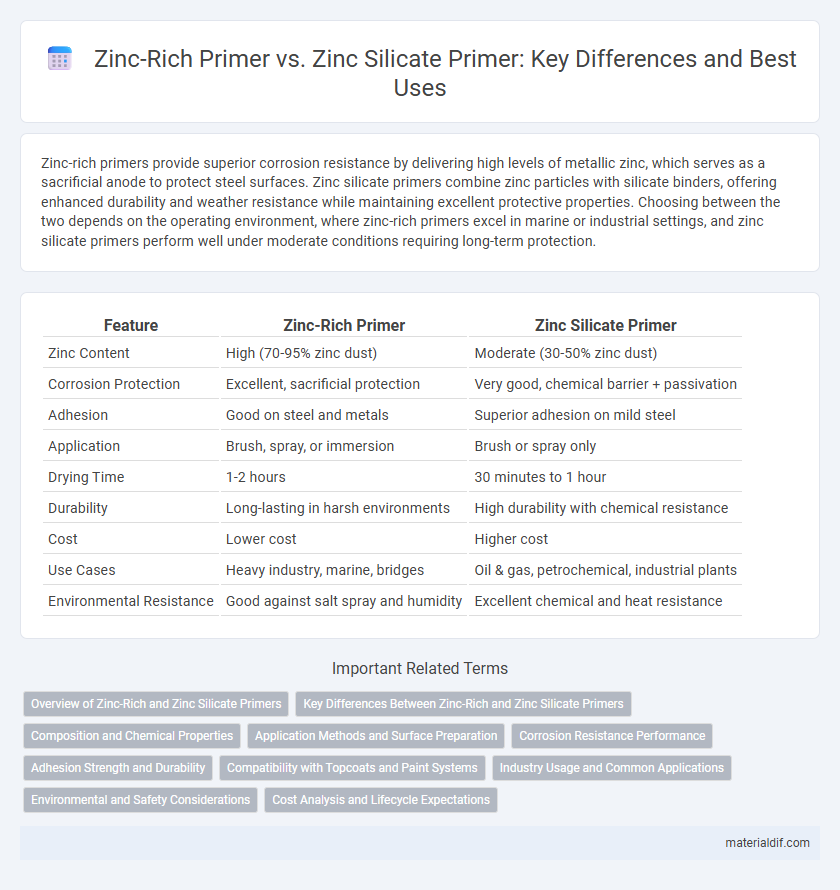

Table of Comparison

| Feature | Zinc-Rich Primer | Zinc Silicate Primer |

|---|---|---|

| Zinc Content | High (70-95% zinc dust) | Moderate (30-50% zinc dust) |

| Corrosion Protection | Excellent, sacrificial protection | Very good, chemical barrier + passivation |

| Adhesion | Good on steel and metals | Superior adhesion on mild steel |

| Application | Brush, spray, or immersion | Brush or spray only |

| Drying Time | 1-2 hours | 30 minutes to 1 hour |

| Durability | Long-lasting in harsh environments | High durability with chemical resistance |

| Cost | Lower cost | Higher cost |

| Use Cases | Heavy industry, marine, bridges | Oil & gas, petrochemical, industrial plants |

| Environmental Resistance | Good against salt spray and humidity | Excellent chemical and heat resistance |

Overview of Zinc-Rich and Zinc Silicate Primers

Zinc-rich primers contain high concentrations of metallic zinc particles that provide sacrificial corrosion protection by galvanic action on steel surfaces. Zinc silicate primers combine zinc dust with silicate binders, offering superior chemical resistance and durability in harsh industrial environments. Both primers enhance steel longevity, but zinc silicate formulations typically deliver higher abrasion resistance and faster curing times.

Key Differences Between Zinc-Rich and Zinc Silicate Primers

Zinc-rich primers contain a high percentage of zinc dust, providing excellent cathodic protection by acting as a sacrificial anode on metal surfaces, while zinc silicate primers combine zinc dust with silicate binders for enhanced durability and chemical resistance. Zinc-rich primers are often preferred for environments with high corrosion risk due to their superior conductivity, whereas zinc silicate primers offer better adhesion and long-term protection against harsh chemicals and weathering. The choice between the two depends on the specific application needs, such as exposure conditions and desired longevity of the protective coating.

Composition and Chemical Properties

Zinc-rich primers consist primarily of metallic zinc dust suspended in a resin binder, providing excellent cathodic protection through galvanic action. Zinc silicate primers combine zinc dust with silicate-based binders that form a hard, chemically resistant film upon curing, enhancing corrosion resistance and durability. The chemical properties of zinc silicate primers offer superior adhesion and weather resistance compared to standard zinc-rich primers due to their inorganic silicate matrix.

Application Methods and Surface Preparation

Zinc-rich primers require thorough surface cleaning and often need abrasive blasting to ensure optimal adhesion and corrosion resistance, while zinc silicate primers demand a dry and oil-free surface, with blast cleaning to a near-white metal standard for best performance. Application of zinc-rich primers typically involves spray or brush methods, allowing for thicker coatings and flexibility in thickness control. Zinc silicate primers are commonly applied by spray techniques, requiring strict adherence to curing conditions to achieve their full protective properties.

Corrosion Resistance Performance

Zinc-rich primers offer superior corrosion resistance by providing a sacrificial barrier that protects steel through galvanic action, effectively preventing rust formation in harsh environments. Zinc silicate primers combine the galvanic protection of zinc with a chemically resistant silicate binder, enhancing durability and adhesion on metal surfaces exposed to industrial pollutants. Both primers excel in corrosion resistance, but zinc silicate primers demonstrate longer-lasting protection in aggressive marine and chemical atmospheres due to their enhanced film integrity and moisture resistance.

Adhesion Strength and Durability

Zinc-rich primers offer superior adhesion strength due to their high zinc content, promoting excellent corrosion resistance on steel surfaces through cathodic protection. Zinc silicate primers provide enhanced durability by forming a dense, inorganic film that withstands harsh environmental conditions and chemical exposure. Both primers are effective, but zinc silicate primers typically outperform in long-term durability, while zinc-rich primers excel in immediate adhesion strength.

Compatibility with Topcoats and Paint Systems

Zinc-rich primers offer superior compatibility with a wide range of topcoats and paint systems, facilitating strong adhesion and extended corrosion protection in industrial coatings. Zinc silicate primers require specific topcoats designed to accommodate their solvent-based nature and high pH, limiting their compatibility scope. Selecting the appropriate primer based on the topcoat chemistry ensures optimal performance and longevity of the coating system.

Industry Usage and Common Applications

Zinc-rich primers are extensively used in heavy industrial environments such as shipbuilding, steel fabrication, and infrastructure projects due to their superior cathodic protection and corrosion resistance on steel surfaces. Zinc silicate primers are preferred in industries requiring high-performance coatings with excellent chemical and abrasion resistance, including petrochemical plants and bridges, often applied in areas exposed to harsh environmental conditions. Both primers serve critical roles in prolonging the lifespan of metal structures, with zinc-rich primers favored for maintenance and zinc silicate primers for initial protective coatings in demanding industrial settings.

Environmental and Safety Considerations

Zinc-rich primers contain high levels of zinc dust, offering excellent corrosion protection but posing inhalation risks due to airborne particles during application, requiring adequate ventilation and protective equipment. Zinc silicate primers, formulated with zinc silicate binders, emit fewer volatile organic compounds (VOCs) and are considered more environmentally friendly, though they often require careful handling to prevent silica dust exposure. Both primers contribute to sustainable corrosion control, but zinc silicate primers generally provide a safer environmental and health profile when proper application protocols are followed.

Cost Analysis and Lifecycle Expectations

Zinc-rich primers generally offer lower upfront costs compared to zinc silicate primers but may require more frequent maintenance, affecting overall lifecycle expenses. Zinc silicate primers, despite higher initial investment, provide superior corrosion resistance and longer service life, reducing long-term costs associated with repairs and repainting. Evaluating total cost of ownership, zinc silicate primers often prove more economical over extended periods due to enhanced durability and reduced maintenance frequency.

Zinc-rich primer vs zinc silicate primer Infographic

materialdif.com

materialdif.com