Sheet zinc offers uniform thickness and smooth surfaces ideal for precise architectural applications, while rolled zinc provides flexibility and is easier to mold for curved or irregular shapes. Rolled zinc typically comes in coils, making it suitable for larger projects requiring continuous material, whereas sheet zinc is cut into flat panels for straightforward installation. Both forms provide excellent corrosion resistance and long-lasting durability in roofing and cladding.

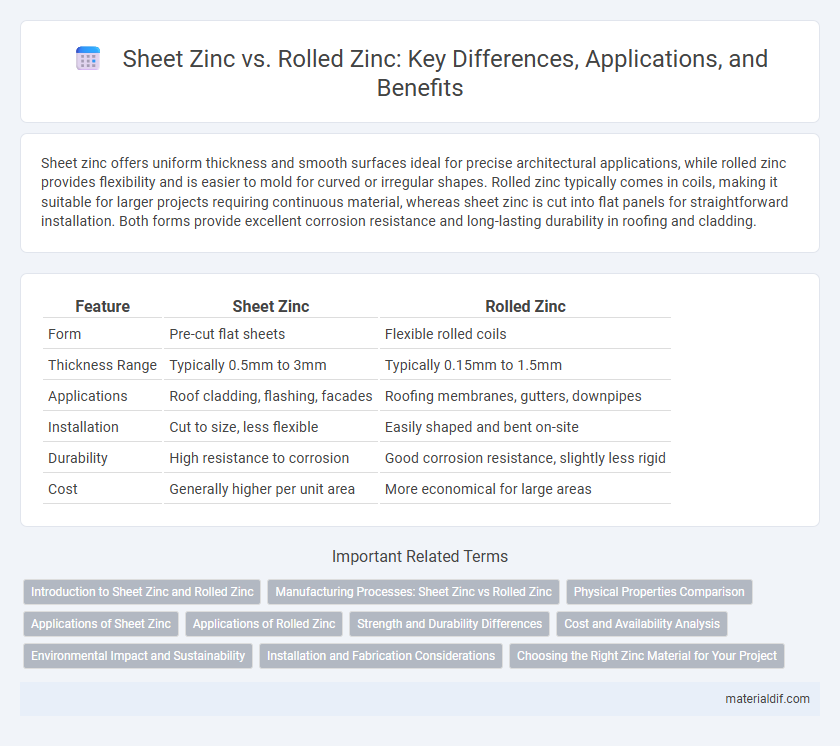

Table of Comparison

| Feature | Sheet Zinc | Rolled Zinc |

|---|---|---|

| Form | Pre-cut flat sheets | Flexible rolled coils |

| Thickness Range | Typically 0.5mm to 3mm | Typically 0.15mm to 1.5mm |

| Applications | Roof cladding, flashing, facades | Roofing membranes, gutters, downpipes |

| Installation | Cut to size, less flexible | Easily shaped and bent on-site |

| Durability | High resistance to corrosion | Good corrosion resistance, slightly less rigid |

| Cost | Generally higher per unit area | More economical for large areas |

Introduction to Sheet Zinc and Rolled Zinc

Sheet zinc refers to zinc metal processed into thin, flat pieces typically used in roofing, cladding, and various industrial applications due to its durability and corrosion resistance. Rolled zinc is produced by passing molten zinc through rollers, creating flexible, uniform sheets with enhanced structural integrity and consistent thickness. Both sheet zinc and rolled zinc offer high purity and excellent workability, making them essential materials in construction and manufacturing industries.

Manufacturing Processes: Sheet Zinc vs Rolled Zinc

Sheet zinc is produced by casting molten zinc into slabs followed by hot rolling to achieve uniform thickness and surface finish, offering precise dimensional control. Rolled zinc undergoes repeated cold rolling after initial hot rolling, enhancing mechanical strength, surface smoothness, and flexibility for specialized applications. The choice between sheet and rolled zinc depends on required physical properties and manufacturing efficiency for targeted industrial uses.

Physical Properties Comparison

Sheet zinc exhibits a smooth, flat surface with consistent thickness, making it ideal for precise applications requiring structural rigidity and dimensional accuracy. Rolled zinc, produced by passing molten zinc through rollers, offers enhanced flexibility and a slightly rougher texture, which improves adhesion in coatings and galvanizing processes. Physically, sheet zinc tends to have higher tensile strength and hardness, while rolled zinc provides better malleability and elongation, catering to different industrial needs.

Applications of Sheet Zinc

Sheet zinc is widely used in architectural applications such as roofing, cladding, and facade panels due to its durability, corrosion resistance, and aesthetic appeal. It is favored for creating custom shapes and detailed designs in construction, offering excellent workability compared to rolled zinc, which is primarily used for industrial processes and large-scale metal coatings. The precise thickness and uniformity of sheet zinc make it ideal for artisanal metalwork and protective coverings in both residential and commercial buildings.

Applications of Rolled Zinc

Rolled zinc offers enhanced flexibility and uniform thickness compared to sheet zinc, making it ideal for intricate roofing designs, facades, and custom architectural components. Its superior malleability allows for precise shaping and bending, which is crucial in applications like gutters, flashing, and decorative elements. Rolled zinc's consistent quality ensures durability and resistance to corrosion, particularly in outdoor construction and industrial uses.

Strength and Durability Differences

Sheet zinc offers higher tensile strength and enhanced durability compared to rolled zinc due to its thicker gauge and solid structure. Rolled zinc, being thinner and more flexible, exhibits less mechanical strength but provides superior malleability for intricate applications. The density and manufacturing process of sheet zinc result in better resistance to impact and corrosion, extending its lifespan in harsh environments.

Cost and Availability Analysis

Sheet zinc typically has a higher cost due to the extensive manufacturing process required to produce uniform thickness and smooth surfaces, making it less readily available in bulk quantities. Rolled zinc, produced through a mechanical rolling process, tends to be more cost-effective and widely available, especially for large-scale industrial applications. Market factors such as regional supply chains and demand fluctuations also influence the price and accessibility of both sheet and rolled zinc products.

Environmental Impact and Sustainability

Sheet zinc production typically involves less energy consumption compared to rolled zinc due to simpler processing steps, resulting in a lower carbon footprint. Rolled zinc, while requiring more intensive manufacturing, offers enhanced material durability that can extend product lifespan and reduce resource replacement frequency. Both forms support sustainability through zinc's natural recyclability, with sheet zinc often preferred in applications favoring minimal environmental disturbance.

Installation and Fabrication Considerations

Sheet zinc offers ease of installation due to its uniform thickness and flat form, enabling precise cutting and fitting for roofing, cladding, and gutter applications. Rolled zinc provides enhanced flexibility and can accommodate complex shapes and curves during fabrication, making it ideal for custom architectural details and seamless joints. Both forms require proper handling to avoid surface scratches, with sheet zinc better suited for rigid structures while rolled zinc excels in malleability and contouring.

Choosing the Right Zinc Material for Your Project

Sheet zinc offers uniform thickness and smooth surface ideal for precise architectural cladding and decorative applications, while rolled zinc provides flexibility and ease of installation for complex shapes and curved surfaces. Considering project requirements such as durability, weather resistance, and aesthetic appeal helps determine whether sheet zinc or rolled zinc best suits roofing, gutters, or flashings. Evaluating zinc grades like high-purity architectural zinc versus alloyed rolled zinc ensures optimal performance and longevity in specific environmental conditions.

Sheet zinc vs rolled zinc Infographic

materialdif.com

materialdif.com