Zinc oxide and zinc carbonate are commonly used zinc compounds with distinct properties and applications in pet care. Zinc oxide is often preferred for its antimicrobial and soothing effects, making it useful in topical treatments for skin irritations and infections in pets. Zinc carbonate, while less reactive, serves as a dietary supplement to support overall zinc levels, crucial for immune function and coat health.

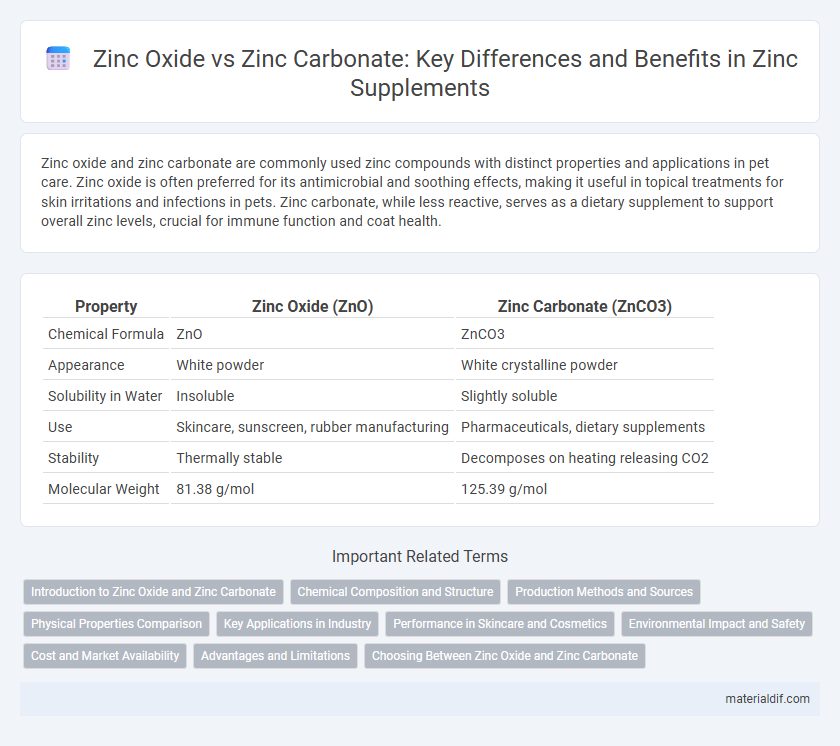

Table of Comparison

| Property | Zinc Oxide (ZnO) | Zinc Carbonate (ZnCO3) |

|---|---|---|

| Chemical Formula | ZnO | ZnCO3 |

| Appearance | White powder | White crystalline powder |

| Solubility in Water | Insoluble | Slightly soluble |

| Use | Skincare, sunscreen, rubber manufacturing | Pharmaceuticals, dietary supplements |

| Stability | Thermally stable | Decomposes on heating releasing CO2 |

| Molecular Weight | 81.38 g/mol | 125.39 g/mol |

Introduction to Zinc Oxide and Zinc Carbonate

Zinc oxide is a white, inorganic compound widely used as a pigment, sunscreen agent, and antimicrobial additive due to its excellent UV absorption and antibacterial properties. Zinc carbonate, a white, powdery mineral, primarily serves as a source of zinc in dietary supplements and pharmaceuticals, valued for its controlled zinc release and antacid properties. Both compounds play crucial roles in industrial, cosmetic, and health-related applications, with zinc oxide known for topical protection and zinc carbonate for dietary supplementation.

Chemical Composition and Structure

Zinc oxide (ZnO) consists of zinc ions bonded to oxide ions, forming a hexagonal crystal structure with strong ionic and covalent characteristics, making it highly stable and widely used in cosmetics and pharmaceuticals. Zinc carbonate (ZnCO3) contains zinc ions combined with carbonate anions (CO3^2-), resulting in a rhombohedral crystal system that decomposes upon heating to release carbon dioxide. The distinct chemical compositions lead to differing physical properties and applications, with ZnO being more thermally stable and ZnCO3 serving as a precursor in various zinc compounds.

Production Methods and Sources

Zinc oxide is primarily produced by the French process, which involves the oxidation of zinc vapor at high temperatures, or by the American process utilizing direct oxidation of zinc metal. Zinc carbonate naturally occurs as the mineral smithsonite and is obtained through mining or synthesized by precipitating zinc salts with sodium carbonate. Industrial zinc oxide mainly derives from high-purity zinc metal, while zinc carbonate production relies on chemical precipitation or extraction from carbonate-rich ores.

Physical Properties Comparison

Zinc oxide appears as a white, powdery solid with a melting point around 1975degC and exhibits low solubility in water, whereas zinc carbonate presents as a white, crystalline solid with a melting point near 300degC and higher water solubility. Zinc oxide's density is approximately 5.6 g/cm3, contrasting with zinc carbonate's density of about 3.3 g/cm3, indicating significant differences in their physical structure. Both compounds differ in thermal stability and reactivity, with zinc oxide remaining stable at higher temperatures compared to the decomposition-prone zinc carbonate.

Key Applications in Industry

Zinc oxide is widely used in the rubber industry as a vulcanization activator, enhancing the elasticity and durability of tires and other rubber products. In cosmetics and pharmaceuticals, zinc oxide serves as a broad-spectrum UV blocker and skin protectant, commonly found in sunscreens and ointments. Zinc carbonate is primarily utilized in the ceramics and glass industries as a fluxing agent, improving the melting properties and surface finish of materials.

Performance in Skincare and Cosmetics

Zinc oxide offers superior UV protection and anti-inflammatory properties, making it a preferred ingredient in sunscreens and soothing skincare products. Zinc carbonate, while providing mild antimicrobial benefits, is less effective in sun protection and is often used as a pH adjuster or mild astringent. The mineral's particle size and formulation significantly influence the performance of zinc oxide in cosmetic formulations, delivering enhanced skin barrier support and reduced irritation.

Environmental Impact and Safety

Zinc oxide presents a lower environmental risk compared to zinc carbonate due to its stable chemical structure, reducing metal ion leaching in water sources. Zinc carbonate, while commonly used in industrial applications, can release zinc ions more readily, potentially leading to aquatic toxicity and soil contamination. Safety data indicates zinc oxide is less hazardous to human health on inhalation or skin contact, whereas zinc carbonate requires more stringent handling protocols to prevent respiratory and dermal exposure.

Cost and Market Availability

Zinc oxide generally commands a higher price than zinc carbonate due to its extensive use in industries such as rubber, cosmetics, and pharmaceuticals, driving greater demand and production costs. Zinc carbonate is more affordable and widely available, often utilized as a zinc supplement and in agricultural applications, benefiting from simpler synthesis and lower purity requirements. Market availability of zinc oxide is robust in developed economies with advanced manufacturing, while zinc carbonate sees broader distribution in regions focused on basic industrial and nutritional uses.

Advantages and Limitations

Zinc oxide offers superior UV protection and antimicrobial properties, making it ideal for skincare and sunscreen formulations, whereas zinc carbonate provides better stability and is commonly used as a dietary supplement and in industrial applications. Zinc oxide's strong opacity and chemical resistance enhance its effectiveness in paints and coatings, while zinc carbonate's lower toxicity and ease of absorption make it suitable for pharmaceutical uses. Limitations of zinc oxide include potential skin irritation in sensitive individuals, whereas zinc carbonate has limited use in high-temperature processes due to decomposition.

Choosing Between Zinc Oxide and Zinc Carbonate

Zinc oxide and zinc carbonate serve distinct roles in various applications, with zinc oxide favored for its superior UV protection, antibacterial properties, and use in skincare formulations and rubber manufacturing. Zinc carbonate, often used as a dietary supplement and in pharmaceutical preparations, offers less UV protection but provides bioavailable zinc essential for metabolic processes. Selecting between zinc oxide and zinc carbonate depends on the specific needs for skin protection, industrial use, or nutritional supplementation.

Zinc Oxide vs Zinc Carbonate Infographic

materialdif.com

materialdif.com