Zinc anodes serve as sacrificial components, protecting metal structures by corroding preferentially in electrochemical cells, while zinc cathodes act as the site for reduction reactions where zinc ions gain electrons. In applications like marine cathodic protection or zinc-air batteries, anodes release zinc ions into the electrolyte, preventing corrosion of the protected metal. Understanding the distinct roles of zinc anodes and cathodes is essential for optimizing corrosion resistance and battery performance.

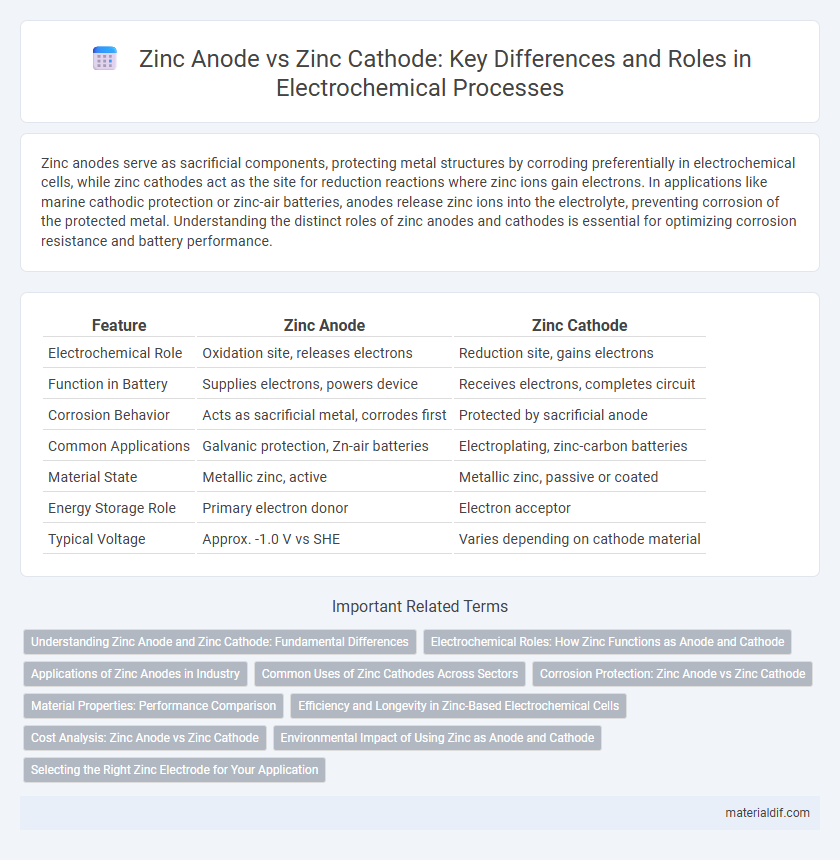

Table of Comparison

| Feature | Zinc Anode | Zinc Cathode |

|---|---|---|

| Electrochemical Role | Oxidation site, releases electrons | Reduction site, gains electrons |

| Function in Battery | Supplies electrons, powers device | Receives electrons, completes circuit |

| Corrosion Behavior | Acts as sacrificial metal, corrodes first | Protected by sacrificial anode |

| Common Applications | Galvanic protection, Zn-air batteries | Electroplating, zinc-carbon batteries |

| Material State | Metallic zinc, active | Metallic zinc, passive or coated |

| Energy Storage Role | Primary electron donor | Electron acceptor |

| Typical Voltage | Approx. -1.0 V vs SHE | Varies depending on cathode material |

Understanding Zinc Anode and Zinc Cathode: Fundamental Differences

Zinc anodes serve as sacrificial electrodes that corrode to protect cathodic metal surfaces from oxidation, making them essential in corrosion prevention systems like galvanic protection. Zinc cathodes, by contrast, act as the protected metal surfaces where reduction reactions occur, maintaining their integrity while the anode corrodes. Understanding the electrochemical roles of zinc anodes and cathodes highlights their fundamental differences in redox processes and applications in corrosion control.

Electrochemical Roles: How Zinc Functions as Anode and Cathode

Zinc functions as an anode by undergoing oxidation, releasing electrons and forming Zn2+ ions, which is essential in galvanic cells and corrosion protection through sacrificial anodes. As a cathode, zinc undergoes reduction reactions, typically gaining electrons to drive electrochemical processes in certain batteries like zinc-air cells. These distinct electrochemical roles highlight zinc's versatility in energy storage and metal protection applications.

Applications of Zinc Anodes in Industry

Zinc anodes serve as sacrificial anodes in cathodic protection systems, widely used to prevent corrosion in pipelines, ship hulls, and underground storage tanks. Their electrochemical properties allow them to corrode preferentially, safeguarding steel structures and extending operational lifespan. Industrial applications rely on zinc anodes to maintain structural integrity in marine, oil and gas, and water treatment facilities.

Common Uses of Zinc Cathodes Across Sectors

Zinc cathodes serve as a fundamental raw material in galvanizing processes, protecting steel structures from corrosion in construction and automotive sectors. They are also extensively utilized in the production of zinc-based alloys and die-casting components, crucial for electrical and mechanical industries. Furthermore, zinc cathodes play a vital role in the manufacturing of batteries, contributing to energy storage solutions across consumer electronics and renewable energy applications.

Corrosion Protection: Zinc Anode vs Zinc Cathode

Zinc anodes serve as sacrificial metals that corrode preferentially, offering effective corrosion protection to steel structures by acting as a negative electrode. In contrast, zinc cathodes do not corrode since they function as the positive electrode, receiving electron flow during electrochemical reactions. This difference makes zinc anodes the primary choice for cathodic protection systems to prevent rust and extend the lifespan of metal surfaces.

Material Properties: Performance Comparison

Zinc anodes exhibit high electrochemical activity, making them ideal for sacrificial corrosion protection due to their ability to easily oxidize and release electrons. Zinc cathodes, in contrast, serve as electron acceptors, showcasing lower electrochemical reactivity but providing structural stability in electrochemical cells. The performance comparison reveals that zinc anodes enable efficient corrosion control through predictable material degradation, while zinc cathodes contribute primarily to maintaining circuit integrity with minimal material consumption.

Efficiency and Longevity in Zinc-Based Electrochemical Cells

Zinc anodes in electrochemical cells offer higher efficiency due to their sacrificial nature, enabling consistent electron flow and prolonged cell operation. Zinc cathodes, while less common, contribute to improved longevity by reducing passivation and enhancing reversibility in redox reactions. Optimizing the anode-to-cathode ratio in zinc-based systems maximizes both energy output and cycle life.

Cost Analysis: Zinc Anode vs Zinc Cathode

Zinc anodes generally offer a lower initial cost compared to zinc cathodes, making them more economical for large-scale applications such as corrosion protection in pipelines and marine structures. Zinc cathodes, while typically more expensive upfront, provide higher efficiency and longer service life, reducing replacement and maintenance expenses over time. Cost analysis must balance the upfront investment in zinc cathodes against the frequent replacement cycle and potential operational downtime associated with zinc anodes.

Environmental Impact of Using Zinc as Anode and Cathode

Zinc anodes, widely used in galvanic corrosion protection, tend to release zinc ions into the environment, which can accumulate in aquatic ecosystems and pose toxicity risks to marine life. Zinc cathodes, commonly utilized in batteries, often involve more complex recycling processes to mitigate hazardous waste, reducing long-term environmental contamination. The overall environmental impact depends on the application, with zinc anodes contributing primarily to localized metal ion pollution, while zinc cathodes raise concerns about resource management and waste disposal.

Selecting the Right Zinc Electrode for Your Application

Selecting the right zinc electrode depends on the specific electrochemical process and desired reaction; zinc anodes serve as the sacrificial electrode in corrosion protection by oxidizing and preventing metal degradation, while zinc cathodes function as the reduction site in batteries or electroplating. For corrosion prevention in marine or underground applications, zinc anodes provide effective galvanic protection due to their high corrosion rate and electrical conductivity. Conversely, zinc cathodes are ideal in battery systems like zinc-air or alkaline batteries where zinc ions are reduced to store or release energy efficiently.

Zinc Anode vs Zinc Cathode Infographic

materialdif.com

materialdif.com