Galvanized zinc involves applying a molten zinc coating to steel for superior corrosion protection, creating a robust barrier against rust. Cold galvanizing uses zinc-rich paints or sprays that adhere to metal surfaces, providing a flexible and convenient option for smaller repairs or less exposed areas. Both methods enhance the durability of pet enclosures and outdoor fixtures, but galvanized zinc offers longer-lasting protection in harsh environments.

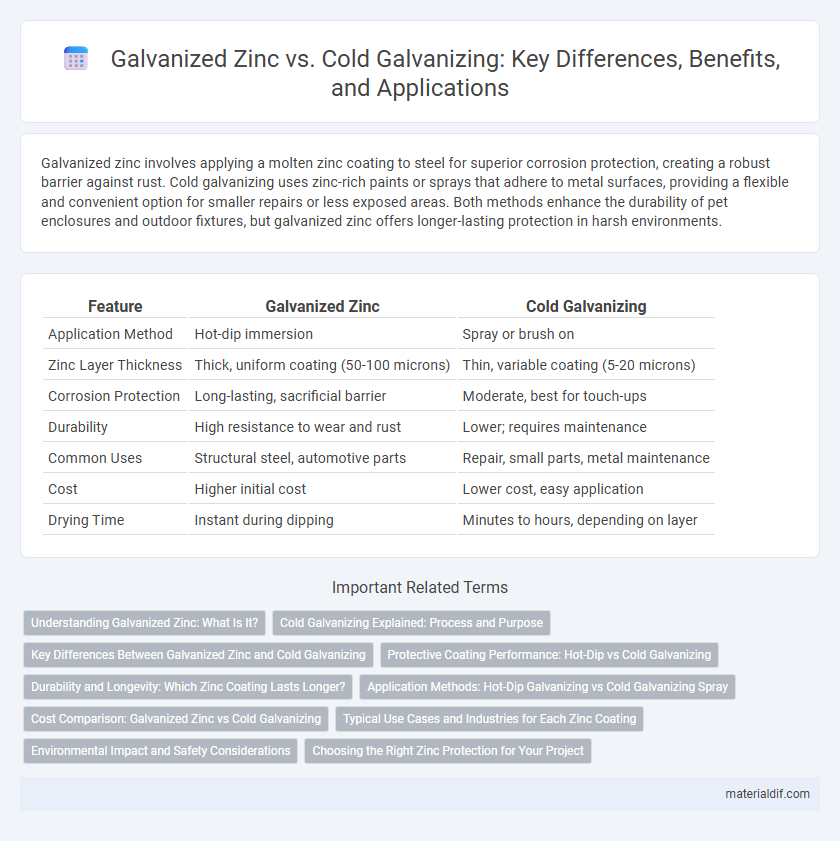

Table of Comparison

| Feature | Galvanized Zinc | Cold Galvanizing |

|---|---|---|

| Application Method | Hot-dip immersion | Spray or brush on |

| Zinc Layer Thickness | Thick, uniform coating (50-100 microns) | Thin, variable coating (5-20 microns) |

| Corrosion Protection | Long-lasting, sacrificial barrier | Moderate, best for touch-ups |

| Durability | High resistance to wear and rust | Lower; requires maintenance |

| Common Uses | Structural steel, automotive parts | Repair, small parts, metal maintenance |

| Cost | Higher initial cost | Lower cost, easy application |

| Drying Time | Instant during dipping | Minutes to hours, depending on layer |

Understanding Galvanized Zinc: What Is It?

Galvanized zinc is a protective coating applied to steel or iron through hot-dip galvanizing, where the metal is immersed in molten zinc, forming a durable, corrosion-resistant layer. This process creates a metallurgical bond that enhances longevity by preventing rust and corrosion, making it ideal for outdoor structures. Cold galvanizing, by contrast, involves applying zinc-rich paint containing finely ground zinc dust, providing a protective barrier without the metallurgical bonding of hot-dip galvanizing.

Cold Galvanizing Explained: Process and Purpose

Cold galvanizing involves applying a zinc-rich paint or coating to a metal surface, creating a protective barrier against corrosion without the need for high-temperature processes. This method relies on zinc particles in the coating to provide sacrificial protection, preventing rust by corroding before the underlying steel. Cold galvanizing is ideal for maintenance, touch-ups, and complex structures where traditional hot-dip galvanizing is impractical.

Key Differences Between Galvanized Zinc and Cold Galvanizing

Galvanized zinc involves a hot-dip process where steel is coated with molten zinc, creating a thick, durable layer that offers long-lasting corrosion resistance suitable for heavy-duty applications. Cold galvanizing uses zinc-rich paint applied at room temperature, providing a protective barrier that is less thick and generally suited for touch-ups or light protection. The key differences include coating thickness, application method, and durability, with hot-dip galvanizing being more robust and cold galvanizing offering convenience and ease of application.

Protective Coating Performance: Hot-Dip vs Cold Galvanizing

Hot-dip galvanized zinc coating provides superior protective performance through a thick, metallurgically bonded layer that offers enhanced corrosion resistance and durability compared to cold galvanizing. Cold galvanizing, which applies a zinc-rich paint or spray, creates a sacrificial barrier that protects the underlying metal but typically has thinner coverage and less adhesion strength. Hot-dip galvanizing ensures longer-lasting protection in harsh environments due to its robust coating thickness and metallurgical bonding, whereas cold galvanizing is best suited for touch-ups and less demanding applications.

Durability and Longevity: Which Zinc Coating Lasts Longer?

Galvanized zinc coatings, created by hot-dipping steel into molten zinc, offer superior durability and longevity due to their thick, metallurgically bonded layer that resists corrosion even in harsh environments. Cold galvanizing, involving zinc-rich paint applied at room temperature, provides good protection but generally has a thinner, less robust coating that wears faster under mechanical stress or prolonged exposure to moisture. For applications demanding maximum corrosion resistance and extended lifespan, hot-dip galvanized zinc is the preferred choice over cold galvanizing.

Application Methods: Hot-Dip Galvanizing vs Cold Galvanizing Spray

Hot-dip galvanizing involves immersing steel in molten zinc, creating a thick, durable coating ideal for heavy-duty corrosion protection in industrial and outdoor environments. Cold galvanizing spray applies a zinc-rich paint at ambient temperature, suitable for maintenance and touch-up on galvanized surfaces or new steel where hot-dipping is impractical. Hot-dip provides a metallurgically bonded layer with superior abrasion resistance, while cold galvanizing spray offers ease of application and quick drying for localized repairs.

Cost Comparison: Galvanized Zinc vs Cold Galvanizing

Galvanized zinc typically incurs higher upfront costs due to the hot-dip process, which involves immersing steel in molten zinc for a durable coating. Cold galvanizing, using zinc-rich paint, offers a more cost-effective alternative with lower application expenses and minimal equipment requirements. However, long-term maintenance costs may vary as galvanized zinc provides superior corrosion resistance, potentially reducing the frequency of reapplication compared to cold galvanizing.

Typical Use Cases and Industries for Each Zinc Coating

Galvanized zinc coatings are commonly used in heavy-duty applications such as automotive manufacturing, construction steel frameworks, and infrastructure projects due to their superior corrosion resistance and durability. Cold galvanizing, often applied through zinc-rich paints, is preferred for maintenance and repair in industries like marine, agriculture, and industrial machinery where quick application and touch-up are essential. Both coatings protect steel surfaces, but galvanized zinc is favored for new fabrications while cold galvanizing suits on-site repairs and smaller components.

Environmental Impact and Safety Considerations

Galvanized zinc coatings involve a hot-dip process that produces a robust, long-lasting protective layer but consume significant energy and emit greenhouse gases during manufacturing. Cold galvanizing uses zinc-rich paints applied at ambient temperatures, reducing energy usage and toxic emissions, but may require more frequent reapplication due to thinner coverage. Safety considerations favor cold galvanizing by minimizing worker exposure to high temperatures and fumes, whereas hot-dip galvanizing demands strict controls to handle molten zinc safely.

Choosing the Right Zinc Protection for Your Project

Galvanized zinc coatings provide a robust and uniform layer through hot-dip immersion, offering superior corrosion resistance ideal for heavy-duty structural projects. Cold galvanizing uses zinc-rich paint applied at room temperature, suitable for touch-ups and maintenance with moderate protection for less demanding environments. Selecting the right zinc protection depends on project scale, environmental exposure, and durability requirements to ensure long-lasting metal preservation.

Galvanized Zinc vs Cold Galvanizing Infographic

materialdif.com

materialdif.com