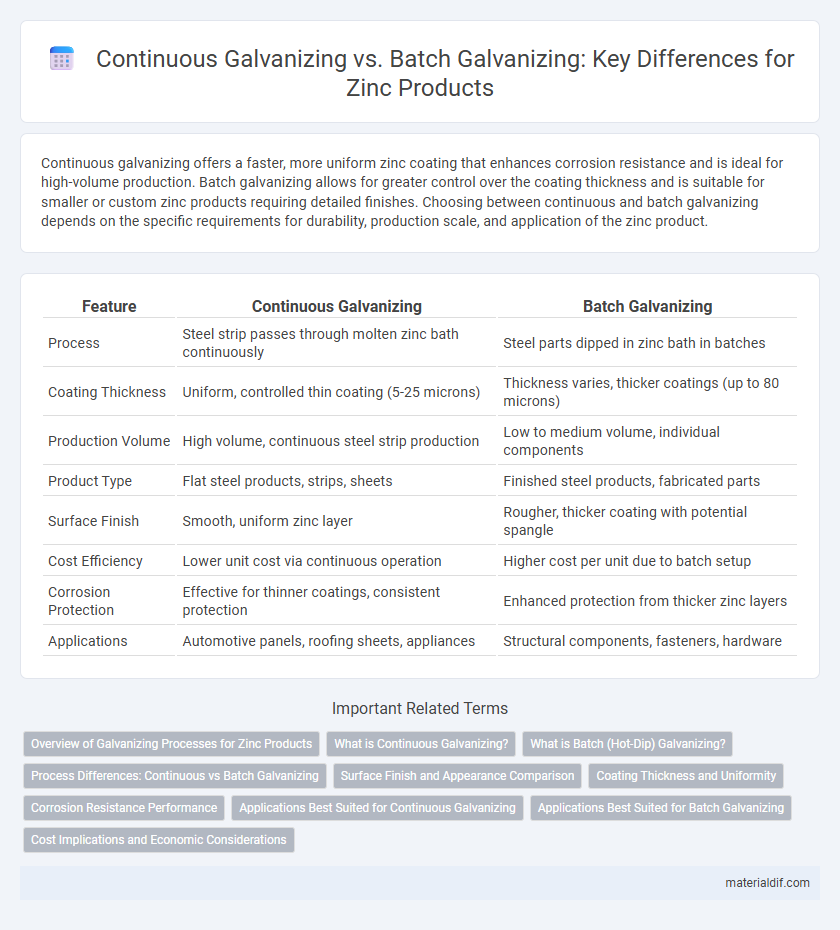

Continuous galvanizing offers a faster, more uniform zinc coating that enhances corrosion resistance and is ideal for high-volume production. Batch galvanizing allows for greater control over the coating thickness and is suitable for smaller or custom zinc products requiring detailed finishes. Choosing between continuous and batch galvanizing depends on the specific requirements for durability, production scale, and application of the zinc product.

Table of Comparison

| Feature | Continuous Galvanizing | Batch Galvanizing |

|---|---|---|

| Process | Steel strip passes through molten zinc bath continuously | Steel parts dipped in zinc bath in batches |

| Coating Thickness | Uniform, controlled thin coating (5-25 microns) | Thickness varies, thicker coatings (up to 80 microns) |

| Production Volume | High volume, continuous steel strip production | Low to medium volume, individual components |

| Product Type | Flat steel products, strips, sheets | Finished steel products, fabricated parts |

| Surface Finish | Smooth, uniform zinc layer | Rougher, thicker coating with potential spangle |

| Cost Efficiency | Lower unit cost via continuous operation | Higher cost per unit due to batch setup |

| Corrosion Protection | Effective for thinner coatings, consistent protection | Enhanced protection from thicker zinc layers |

| Applications | Automotive panels, roofing sheets, appliances | Structural components, fasteners, hardware |

Overview of Galvanizing Processes for Zinc Products

Continuous galvanizing involves passing steel coils through a molten zinc bath, providing uniform zinc coating thickness and enhanced corrosion resistance suitable for high-volume production. Batch galvanizing, also known as hot-dip galvanizing, immerses individual steel items in molten zinc, allowing customized coating thickness but less uniformity and slower processing. Continuous galvanizing is preferred for automotive and construction steel sheets, while batch galvanizing suits complex shapes and smaller-scale applications.

What is Continuous Galvanizing?

Continuous galvanizing is a process where steel strip passes through a molten zinc bath in a continuous line, ensuring consistent and uniform zinc coating. This method enhances corrosion resistance and surface quality while maximizing production efficiency for zinc-coated steel products. Continuous galvanizing is widely used in automotive and construction industries due to its ability to produce high-volume, durable zinc layers.

What is Batch (Hot-Dip) Galvanizing?

Batch hot-dip galvanizing involves immersing steel components into a molten zinc bath to form a robust, corrosion-resistant coating, ideal for irregularly shaped or large items. This process ensures thick, uniform zinc layers through controlled immersion times and temperature, enhancing durability against environmental degradation. Compared to continuous galvanizing, batch galvanizing provides superior coating thickness and adhesion, crucial for heavy-duty applications requiring long-term protection.

Process Differences: Continuous vs Batch Galvanizing

Continuous galvanizing involves passing steel coils through a molten zinc bath at high speeds, enabling uniform zinc coating and consistent thickness ideal for large-scale production. Batch galvanizing, or batch hot-dip galvanizing, immerses steel components individually or in small groups into molten zinc, allowing for variable coating thickness and suitability for irregular shapes or smaller runs. The continuous process offers efficiency and surface smoothness, while batch galvanizing provides flexibility and adaptability to diverse product geometries.

Surface Finish and Appearance Comparison

Continuous galvanizing provides a smoother, more uniform zinc coating with a consistent bright metallic finish, enhancing corrosion resistance and aesthetic appeal. Batch galvanizing often results in a thicker, less uniform zinc layer with potential spangle variations and surface irregularities, leading to a duller, less consistent appearance. The controlled parameters in continuous galvanizing optimize surface texture and color uniformity, making it preferable for applications demanding high-quality finish and visual consistency.

Coating Thickness and Uniformity

Continuous galvanizing delivers superior coating thickness uniformity by applying zinc in a controlled, consistent process on steel sheets, typically achieving thicknesses ranging from 35 to 150 microns. Batch galvanizing, performed on individual steel parts, results in variable coating thickness often between 45 to 85 microns, with less uniform coverage due to dipping time and zinc bath temperature fluctuations. The continuous method ensures a more reliable and predictable protective zinc layer, enhancing corrosion resistance over diverse industrial applications.

Corrosion Resistance Performance

Continuous galvanizing provides superior corrosion resistance due to the uniform zinc coating thickness achieved through the continuous metal immersion process, minimizing exposure to corrosive elements. Batch galvanizing often results in variable coating thickness and potential inconsistencies, leading to less predictable corrosion protection over time. The enhanced bonding and smoother finish in continuous galvanizing extend the durability of zinc-coated steel products in harsh environments.

Applications Best Suited for Continuous Galvanizing

Continuous galvanizing is ideal for large-scale applications such as automotive panels, appliances, and construction materials due to its ability to provide uniform and consistent zinc coatings. This process enhances corrosion resistance and surface quality, making it suitable for high-volume production with stringent durability requirements. Continuous galvanizing is preferred in industries demanding precision and efficiency, including metal roofing, HVAC systems, and electrical enclosures.

Applications Best Suited for Batch Galvanizing

Batch galvanizing is best suited for small to medium-sized steel components, such as fasteners, automotive parts, and architectural hardware, where precise coating thickness and uniformity are critical. This process allows for thorough inspection and quality control, making it ideal for complex shapes and items requiring thicker or specialized zinc coatings. Specialized applications in construction and machinery benefit from batch galvanizing's ability to handle customized orders with enhanced corrosion resistance.

Cost Implications and Economic Considerations

Continuous galvanizing offers lower per-unit costs due to high production efficiency and reduced labor expenses, making it ideal for large-scale zinc-coated steel manufacturing. Batch galvanizing incurs higher operational costs from frequent equipment cleaning and downtime, suited for small runs or custom orders. Economic considerations favor continuous galvanizing when demand is consistent, while batch galvanizing remains cost-effective for specialized, lower-volume zinc products.

Continuous galvanizing vs Batch galvanizing (for zinc products) Infographic

materialdif.com

materialdif.com