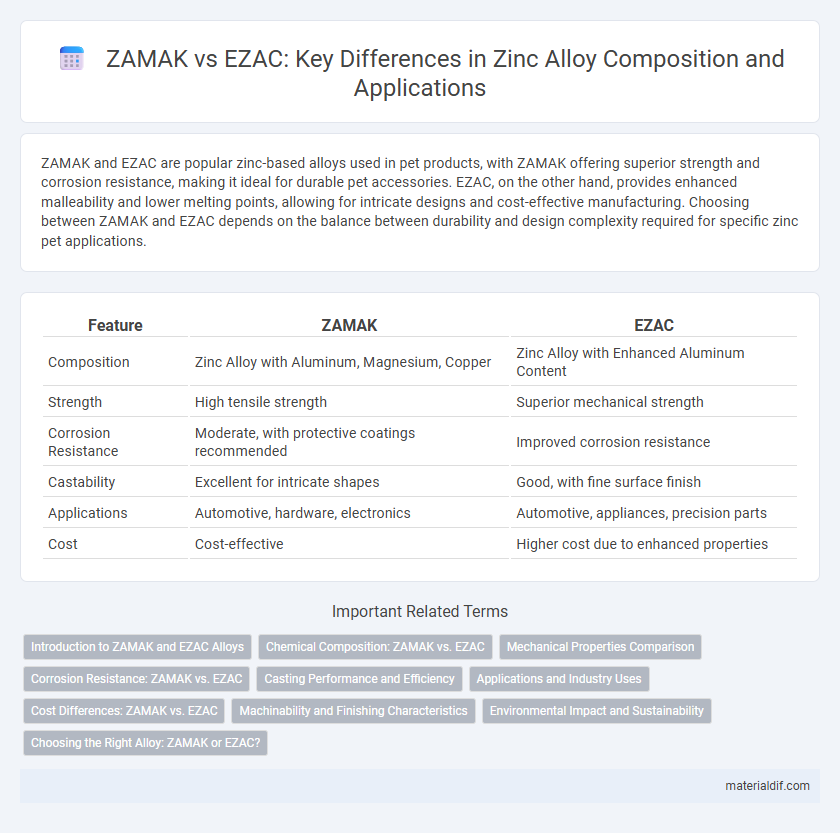

ZAMAK and EZAC are popular zinc-based alloys used in pet products, with ZAMAK offering superior strength and corrosion resistance, making it ideal for durable pet accessories. EZAC, on the other hand, provides enhanced malleability and lower melting points, allowing for intricate designs and cost-effective manufacturing. Choosing between ZAMAK and EZAC depends on the balance between durability and design complexity required for specific zinc pet applications.

Table of Comparison

| Feature | ZAMAK | EZAC |

|---|---|---|

| Composition | Zinc Alloy with Aluminum, Magnesium, Copper | Zinc Alloy with Enhanced Aluminum Content |

| Strength | High tensile strength | Superior mechanical strength |

| Corrosion Resistance | Moderate, with protective coatings recommended | Improved corrosion resistance |

| Castability | Excellent for intricate shapes | Good, with fine surface finish |

| Applications | Automotive, hardware, electronics | Automotive, appliances, precision parts |

| Cost | Cost-effective | Higher cost due to enhanced properties |

Introduction to ZAMAK and EZAC Alloys

ZAMAK and EZAC alloys are prominent zinc-based materials widely used in die casting applications due to their excellent mechanical properties and corrosion resistance. ZAMAK alloys primarily consist of zinc with aluminum, magnesium, and copper additions that improve strength and durability, making them ideal for intricate components in automotive and consumer electronics industries. EZAC alloys offer enhanced alloying elements such as aluminum and copper in different proportions, optimizing casting performance and surface finish for industrial parts requiring higher precision and wear resistance.

Chemical Composition: ZAMAK vs. EZAC

ZAMAK alloys primarily consist of zinc (approximately 88-96%), aluminum (3-5%), magnesium (0.02-0.1%), and copper (up to 1%), providing enhanced strength and corrosion resistance. EZAC, a proprietary zinc alloy, contains a higher percentage of aluminum and copper compared to traditional ZAMAK, improving mechanical properties and thermal stability. The variation in chemical composition between ZAMAK and EZAC directly affects their casting performance, finish quality, and durability in industrial applications.

Mechanical Properties Comparison

ZAMAK alloys, primarily composed of zinc with aluminum, magnesium, and copper, exhibit excellent tensile strength typically ranging from 310 to 380 MPa, making them highly suitable for precision die casting applications. EZAC, an engineered zinc alloy, often demonstrates enhanced elongation and impact resistance compared to standard ZAMAK grades, with tensile strengths generally around 280 to 350 MPa but superior ductility. The mechanical properties comparison highlights ZAMAK's higher yield strength and rigidity, whereas EZAC offers improved toughness and fatigue resistance, optimizing performance based on specific structural requirements.

Corrosion Resistance: ZAMAK vs. EZAC

ZAMAK alloys exhibit moderate corrosion resistance but are prone to surface oxidation and dezincification in harsh environments, limiting their use in highly corrosive conditions. EZAC (Electrolytic Zinc Aluminum Coating) provides superior corrosion resistance by forming a robust, zinc-aluminum barrier that protects the underlying metal from oxidation and environmental degradation. The enhanced protective properties of EZAC make it a preferred choice for applications requiring extended durability in marine and industrial atmospheres.

Casting Performance and Efficiency

ZAMAK alloys demonstrate superior casting performance with excellent fluidity and minimal porosity, yielding high-precision, dimensionally stable components ideal for intricate designs. EZAC alloys offer enhanced efficiency due to faster solidification rates and improved mechanical properties, reducing cycle times and energy consumption during production. The choice between ZAMAK and EZAC depends on balancing detailed finish requirements against cost-effective, rapid casting processes.

Applications and Industry Uses

ZAMAK alloys are widely used in die-casting applications for automotive components, household appliances, and electrical fittings due to their excellent strength, corrosion resistance, and dimensional stability. EZAC, a newer zinc-aluminum-copper alloy, offers improved mechanical properties and fatigue resistance, making it suitable for high-stress parts in industrial machinery and precision instruments. Both alloys are essential in manufacturing, with ZAMAK dominating general-purpose castings and EZAC preferred in specialized engineering sectors requiring enhanced durability.

Cost Differences: ZAMAK vs. EZAC

ZAMAK alloys generally offer lower production costs compared to EZAC due to their widespread availability and established manufacturing processes. EZAC, with its enhanced corrosion resistance and mechanical properties, typically incurs higher material and processing expenses. Cost differences between ZAMAK and EZAC can significantly impact project budgets, making ZAMAK a preferred choice for cost-sensitive applications while EZAC suits higher-performance requirements.

Machinability and Finishing Characteristics

ZAMAK alloys exhibit excellent machinability and provide smooth finishing characteristics, making them ideal for precision components and decorative applications. EZAC alloys, while offering superior corrosion resistance, have slightly reduced machinability and may require specialized tooling for optimal finishing. Both materials benefit from zinc's inherent castability but differ in their suitability for high-precision machining and surface detail quality.

Environmental Impact and Sustainability

ZAMAK and EZAC are zinc alloys used in manufacturing, with ZAMAK primarily composed of zinc, aluminum, magnesium, and copper, while EZAC includes higher aluminum content. EZAC offers enhanced corrosion resistance, reducing the need for frequent replacements and lowering environmental waste. Lifecycle assessments indicate that EZAC's improved durability contributes to greater sustainability by minimizing resource consumption and emissions during production and use.

Choosing the Right Alloy: ZAMAK or EZAC?

ZAMAK and EZAC alloys both consist primarily of zinc, but ZAMAK contains a blend of aluminum, magnesium, and copper, offering high strength and excellent castability, ideal for precision die-casting applications. EZAC, an enhanced zinc-aluminum-copper alloy, provides superior corrosion resistance and improved mechanical properties, making it suitable for components exposed to harsher environments. Selecting between ZAMAK and EZAC depends on specific project requirements, with ZAMAK favored for intricate shapes and EZAC chosen for durability under corrosive conditions.

ZAMAK vs EZAC Infographic

materialdif.com

materialdif.com