Cold forging with zinc allows for increased strength and precision due to work hardening and minimal oxidation, making it ideal for detailed, high-tolerance components. Hot forging, in contrast, offers better ductility and reduced risk of cracking by operating above zinc's recrystallization temperature, suitable for larger or more complex shapes. Selecting the appropriate forging method depends on the balance between mechanical properties and manufacturing requirements in zinc pet applications.

Table of Comparison

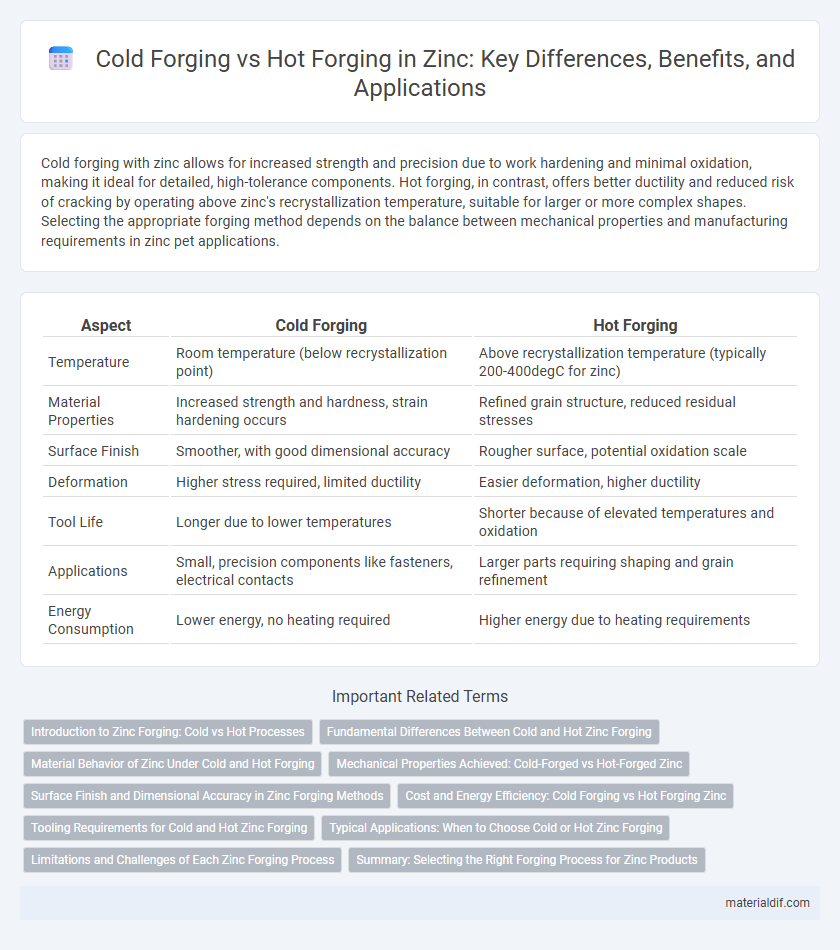

| Aspect | Cold Forging | Hot Forging |

|---|---|---|

| Temperature | Room temperature (below recrystallization point) | Above recrystallization temperature (typically 200-400degC for zinc) |

| Material Properties | Increased strength and hardness, strain hardening occurs | Refined grain structure, reduced residual stresses |

| Surface Finish | Smoother, with good dimensional accuracy | Rougher surface, potential oxidation scale |

| Deformation | Higher stress required, limited ductility | Easier deformation, higher ductility |

| Tool Life | Longer due to lower temperatures | Shorter because of elevated temperatures and oxidation |

| Applications | Small, precision components like fasteners, electrical contacts | Larger parts requiring shaping and grain refinement |

| Energy Consumption | Lower energy, no heating required | Higher energy due to heating requirements |

Introduction to Zinc Forging: Cold vs Hot Processes

Cold forging zinc involves shaping the metal at room temperature, resulting in increased strength and improved surface finish without oxidation risk. Hot forging zinc takes place above its recrystallization temperature, enhancing ductility and enabling complex shapes but may cause surface oxidation. Both methods influence zinc's mechanical properties and application suitability depending on the desired form and performance.

Fundamental Differences Between Cold and Hot Zinc Forging

Cold forging zinc occurs below its recrystallization temperature, resulting in increased strength and improved surface finish due to strain hardening, whereas hot forging zinc takes place above this temperature, allowing easier deformation and reduced internal stresses. The fundamental difference lies in the temperature regime, which affects the metal's microstructure, mechanical properties, and production efficiency. Cold forging produces finer grain structures enhancing tensile strength, while hot forging promotes recrystallization that improves ductility and reduces work hardening in zinc components.

Material Behavior of Zinc Under Cold and Hot Forging

Zinc's behavior during cold forging is characterized by increased hardness and reduced ductility, making deformation more challenging but resulting in enhanced dimensional accuracy and surface finish. In contrast, hot forging zinc, performed above its recrystallization temperature (around 100degC), improves ductility and reduces flow stress, facilitating easier shaping without cracking. Understanding the thermal sensitivity and strain rate dependence of zinc is crucial for optimizing forging parameters and achieving desired mechanical properties.

Mechanical Properties Achieved: Cold-Forged vs Hot-Forged Zinc

Cold forging zinc produces components with higher tensile strength and improved surface finish due to work hardening, while hot forging enhances ductility and reduces internal stresses by recrystallization at elevated temperatures. Cold-forged zinc typically achieves tensile strengths up to 350 MPa, whereas hot-forged zinc offers greater elongation, often exceeding 30%, making it more suitable for complex shapes requiring flexibility. The choice between cold and hot forging directly impacts the mechanical properties essential for applications in automotive and hardware industries.

Surface Finish and Dimensional Accuracy in Zinc Forging Methods

Cold forging of zinc offers superior surface finish due to minimal oxidation and consistent grain structure, resulting in smooth, defect-free surfaces essential for precision components. Hot forging, while enabling easier metal flow, often causes scale formation and surface irregularities that require additional finishing processes. Dimensional accuracy in cold forging surpasses hot forging as lower temperatures reduce thermal expansion and distortion, ensuring tighter tolerances in zinc parts.

Cost and Energy Efficiency: Cold Forging vs Hot Forging Zinc

Cold forging zinc significantly reduces energy consumption compared to hot forging by eliminating the need for heating, resulting in lower operational costs and enhanced cost efficiency. The ambient temperature process minimizes thermal energy requirements, making cold forging a more sustainable and economical choice for zinc manufacturing. Hot forging zinc, while allowing for easier deformation and potential material properties enhancement, incurs higher energy expenses due to prolonged heating and temperature maintenance.

Tooling Requirements for Cold and Hot Zinc Forging

Cold forging zinc demands tooling made from high-strength, wear-resistant materials like hardened steel or carbide to withstand increased stress and maintain dimensional accuracy. Hot forging zinc utilizes tooling that must endure elevated temperatures, often requiring heat-resistant alloys or tool steels with superior thermal fatigue resistance. Proper tooling selection ensures optimal performance, tool life, and surface finish quality during both cold and hot zinc forging processes.

Typical Applications: When to Choose Cold or Hot Zinc Forging

Cold forging with zinc is ideal for producing small, precise components such as fasteners, where dimensional accuracy and surface finish are critical. Hot forging with zinc suits larger or complex parts like automotive or aerospace components requiring enhanced ductility and reduced risk of cracking. Choosing cold or hot zinc forging depends on part size, complexity, and mechanical property requirements in industrial applications.

Limitations and Challenges of Each Zinc Forging Process

Cold forging of zinc presents limitations such as increased tool wear due to the metal's limited ductility at lower temperatures and the risk of surface cracking. Hot forging allows better ductility and moldability of zinc but faces challenges related to oxidation, requiring stringent temperature control to prevent metal degradation. Both processes demand careful consideration of zinc's thermal properties to optimize mechanical performance and minimize defects.

Summary: Selecting the Right Forging Process for Zinc Products

Cold forging of zinc offers superior dimensional accuracy and surface finish, making it ideal for precision components, while hot forging enhances material ductility and reduces internal stresses for complex shapes. Zinc's relatively low melting point (419.5degC) facilitates hot forging at moderate temperatures, improving formability without significant grain growth. Choosing the right process depends on the desired mechanical properties, component geometry, and production volume, optimizing performance and cost-efficiency in zinc product manufacturing.

Cold forging vs Hot forging (with zinc) Infographic

materialdif.com

materialdif.com