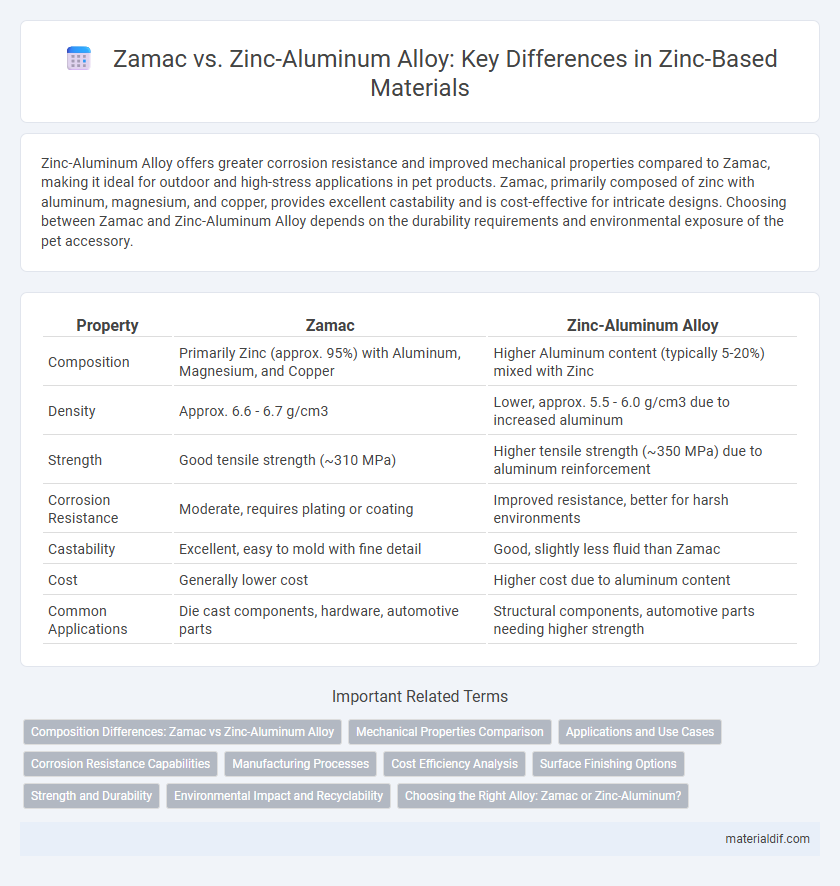

Zinc-Aluminum Alloy offers greater corrosion resistance and improved mechanical properties compared to Zamac, making it ideal for outdoor and high-stress applications in pet products. Zamac, primarily composed of zinc with aluminum, magnesium, and copper, provides excellent castability and is cost-effective for intricate designs. Choosing between Zamac and Zinc-Aluminum Alloy depends on the durability requirements and environmental exposure of the pet accessory.

Table of Comparison

| Property | Zamac | Zinc-Aluminum Alloy |

|---|---|---|

| Composition | Primarily Zinc (approx. 95%) with Aluminum, Magnesium, and Copper | Higher Aluminum content (typically 5-20%) mixed with Zinc |

| Density | Approx. 6.6 - 6.7 g/cm3 | Lower, approx. 5.5 - 6.0 g/cm3 due to increased aluminum |

| Strength | Good tensile strength (~310 MPa) | Higher tensile strength (~350 MPa) due to aluminum reinforcement |

| Corrosion Resistance | Moderate, requires plating or coating | Improved resistance, better for harsh environments |

| Castability | Excellent, easy to mold with fine detail | Good, slightly less fluid than Zamac |

| Cost | Generally lower cost | Higher cost due to aluminum content |

| Common Applications | Die cast components, hardware, automotive parts | Structural components, automotive parts needing higher strength |

Composition Differences: Zamac vs Zinc-Aluminum Alloy

Zamac is primarily composed of approximately 96% zinc with small amounts of aluminum, magnesium, and copper, optimizing strength and castability. In contrast, zinc-aluminum alloys contain higher proportions of aluminum, often ranging from 5% to 27%, which enhance corrosion resistance and mechanical properties. The differing aluminum content and alloying elements significantly impact the physical characteristics and applications of each material.

Mechanical Properties Comparison

Zamac alloys typically exhibit higher tensile strength and better ductility compared to zinc-aluminum alloys, making them more suitable for applications requiring robust mechanical performance. Zinc-aluminum alloys often provide superior corrosion resistance and enhanced castability, but their mechanical strength generally falls short of Zamac's standards. The choice between Zamac and zinc-aluminum alloys depends heavily on the specific mechanical property requirements such as impact resistance and elongation in end-use applications.

Applications and Use Cases

Zamac, a zinc-aluminum alloy with approximately 4% aluminum, is widely used in die-casting applications for automotive parts, hardware, and consumer electronics due to its excellent strength, corrosion resistance, and fine detail reproduction. Zinc-aluminum alloys with varying aluminum content (typically 5-27%) offer enhanced wear resistance and higher temperature tolerance, making them suitable for industrial components, machinery parts, and structural applications. The choice between Zamac and higher aluminum content zinc alloys depends on specific requirements such as mechanical strength, thermal stability, and surface finish in manufacturing processes.

Corrosion Resistance Capabilities

Zamac, primarily composed of zinc with aluminum, magnesium, and copper, offers moderate corrosion resistance suitable for indoor applications. Zinc-aluminum alloys, with higher aluminum content, exhibit superior corrosion resistance due to the enhanced formation of protective oxide layers. These alloys are ideal for outdoor and marine environments where prolonged exposure to moisture and corrosive elements occurs.

Manufacturing Processes

Zamac alloys, primarily composed of zinc with aluminum, magnesium, and copper, are manufactured through die casting, enabling high precision and intricate shapes with excellent surface finishes. Zinc-aluminum alloys often utilize pressure die casting or cold chamber casting to optimize mechanical properties and corrosion resistance, offering durability for automotive and hardware components. Both manufacturing processes emphasize rapid solidification and dimensional stability, though Zamac typically allows for thinner walls and finer details due to its higher fluidity during casting.

Cost Efficiency Analysis

Zamac, primarily composed of zinc with aluminum, magnesium, and copper, offers a lower material cost but exhibits less durability compared to Zinc-Aluminum Alloy, which contains higher aluminum content and enhanced mechanical properties. Zinc-Aluminum Alloy provides superior corrosion resistance and strength, resulting in longer lifespan and reduced maintenance costs, thereby improving cost efficiency in high-performance applications. The trade-off between initial material expense and lifecycle savings makes Zinc-Aluminum Alloy a more cost-effective choice for demanding industrial uses despite higher upfront investment.

Surface Finishing Options

Zamac and Zinc-Aluminum alloys offer distinct surface finishing options that enhance corrosion resistance and aesthetic appeal. Zamac, primarily composed of zinc with aluminum, magnesium, and copper, supports finishes like electroplating, powder coating, and chromate conversion, providing a smooth, uniform surface ideal for decorative applications. Zinc-Aluminum alloys, with higher aluminum content, allow for advanced anodizing and thermal spray coatings, resulting in improved durability and superior corrosion protection in harsh environments.

Strength and Durability

Zamac typically contains about 4% aluminum, 1% magnesium, and minor copper, resulting in good casting fluidity but moderate strength and corrosion resistance. Zinc-aluminum alloys, often with higher aluminum content (up to 30%), offer enhanced strength and superior durability due to improved hardness and better resistance to wear and corrosion. This makes zinc-aluminum alloys preferable for applications demanding greater mechanical performance and longer service life compared to traditional Zamac alloys.

Environmental Impact and Recyclability

Zamac, primarily composed of zinc with aluminum, magnesium, and copper, offers high recyclability due to its widespread acceptance in metal recycling programs, reducing environmental impact by minimizing waste. Zinc-aluminum alloys enhance corrosion resistance, which extends product lifespan and decreases the frequency of replacement, thus lowering overall resource consumption and emissions related to manufacturing. Both materials leverage zinc's natural abundance and recyclability, but Zamac's established recycling infrastructure provides a more streamlined environmental advantage.

Choosing the Right Alloy: Zamac or Zinc-Aluminum?

Zamac, a popular zinc alloy primarily composed of zinc with aluminum, magnesium, and copper, offers excellent castability and high strength, making it ideal for precision die-casting applications. Zinc-aluminum alloys feature higher aluminum content, enhancing corrosion resistance and wear properties, which is beneficial for automotive and industrial components exposed to harsh environments. Selecting between Zamac and zinc-aluminum alloys depends on balancing the need for mechanical strength, surface finish quality, and environmental durability specific to the intended product use.

Zamac vs Zinc-Aluminum Alloy Infographic

materialdif.com

materialdif.com