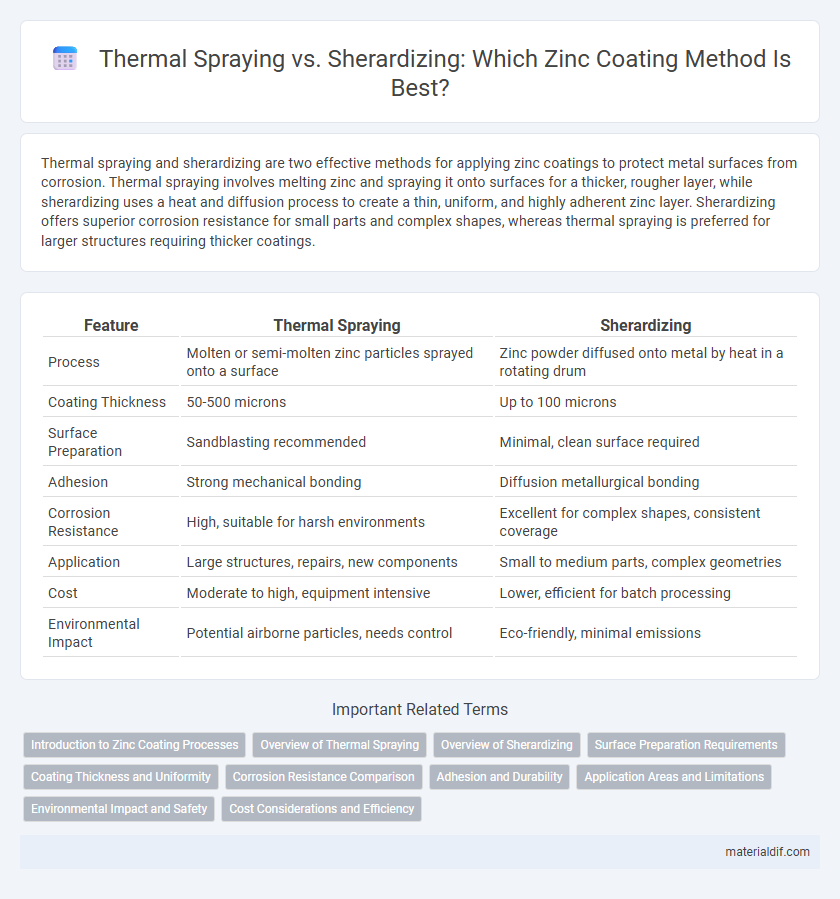

Thermal spraying and sherardizing are two effective methods for applying zinc coatings to protect metal surfaces from corrosion. Thermal spraying involves melting zinc and spraying it onto surfaces for a thicker, rougher layer, while sherardizing uses a heat and diffusion process to create a thin, uniform, and highly adherent zinc layer. Sherardizing offers superior corrosion resistance for small parts and complex shapes, whereas thermal spraying is preferred for larger structures requiring thicker coatings.

Table of Comparison

| Feature | Thermal Spraying | Sherardizing |

|---|---|---|

| Process | Molten or semi-molten zinc particles sprayed onto a surface | Zinc powder diffused onto metal by heat in a rotating drum |

| Coating Thickness | 50-500 microns | Up to 100 microns |

| Surface Preparation | Sandblasting recommended | Minimal, clean surface required |

| Adhesion | Strong mechanical bonding | Diffusion metallurgical bonding |

| Corrosion Resistance | High, suitable for harsh environments | Excellent for complex shapes, consistent coverage |

| Application | Large structures, repairs, new components | Small to medium parts, complex geometries |

| Cost | Moderate to high, equipment intensive | Lower, efficient for batch processing |

| Environmental Impact | Potential airborne particles, needs control | Eco-friendly, minimal emissions |

Introduction to Zinc Coating Processes

Thermal spraying and sherardizing are prominent zinc coating processes used to enhance corrosion resistance of metal surfaces. Thermal spraying involves the projection of molten zinc particles onto substrates, forming a robust and uniform protective layer. Sherardizing, also known as vapor galvanizing, employs zinc powder heated in a rotating drum to diffusely coat complex geometries, ensuring excellent adhesion and coverage in recessed areas.

Overview of Thermal Spraying

Thermal spraying is a versatile coating process that involves the projection of molten or semi-molten zinc particles onto a substrate to provide corrosion resistance. This method allows for precise control of coating thickness and offers excellent adhesion on various materials, making it suitable for complex shapes and large structures. Compared to sherardizing, thermal spraying delivers faster application times and flexibility in zinc coating characteristics.

Overview of Sherardizing

Sherardizing is a thermochemical diffusion process that applies a uniform zinc coating by heating steel parts with zinc dust in a sealed rotating drum at temperatures between 320degC and 450degC. This method creates a metallurgically bonded zinc-iron alloy layer that offers superior corrosion resistance compared to conventional thermal spraying. Sherardizing is particularly effective for small, complex-shaped components requiring consistent coverage without the risk of distortion or high-temperature exposure.

Surface Preparation Requirements

Thermal spraying requires meticulous surface preparation, including abrasive blasting to achieve a roughness profile of 50-100 microns, ensuring optimal adhesion of the molten zinc particles. Sherardizing involves less rigorous surface treatment, typically limited to cleaning and degreasing, as the process relies on diffusion bonding in a heated rotating drum rather than mechanical interlocking. Proper surface preparation directly impacts coating uniformity, corrosion resistance, and long-term durability in both methods.

Coating Thickness and Uniformity

Thermal spraying typically produces zinc coatings between 50 to 200 microns thick, but can exhibit variable uniformity due to the spray angle and surface complexity. Sherardizing achieves a more uniform zinc diffusion layer, usually ranging from 10 to 25 microns in thickness, providing consistent coverage even on intricate geometries. The choice between these methods depends on the required coating thickness and uniformity for the specific corrosion protection application.

Corrosion Resistance Comparison

Thermal spraying provides a thicker zinc coating that offers excellent corrosion resistance by creating a robust physical barrier against environmental factors. Sherardizing embeds zinc particles into the steel substrate through diffusion, resulting in a uniform metallurgical bond that enhances corrosion resistance, particularly in complex shapes and crevices. Sherardizing generally provides superior long-term corrosion protection in aggressive environments due to its uniform coverage and diffusion layer formation.

Adhesion and Durability

Thermal spraying offers superior adhesion by mechanically bonding zinc coatings to substrates through high-velocity particle impact, resulting in robust, thick layers that resist wear and corrosion. Sherardizing chemically diffuses zinc into the metal surface at elevated temperatures, creating a uniform, metallurgically bonded coating with exceptional durability and resistance to flaking. While thermal spraying provides quick application suitable for large or complex parts, sherardizing excels in producing long-lasting, highly adherent zinc coatings ideal for intricate, small components.

Application Areas and Limitations

Thermal spraying of zinc is widely applied in industrial sectors such as power plants, bridges, and offshore structures for corrosion protection due to its versatility in coating irregular surfaces and large-scale components. Sherardizing is primarily used for small steel parts like fasteners and hardware, offering uniform zinc diffusion and superior adhesion but limited by part size and geometry constraints. While thermal spraying allows faster application on large substrates, it requires expensive equipment and may result in less uniform coatings compared to the controlled, environmentally friendly sherardizing process effective for batch treatments.

Environmental Impact and Safety

Thermal spraying zinc involves high-temperature processes that emit significant airborne particles and gases, raising concerns about worker respiratory safety and requiring stringent ventilation controls. Sherardizing zinc powder uses lower temperatures in a closed rotating drum, minimizing airborne emissions and reducing environmental pollution, making it a safer alternative for operators. Waste management in thermal spraying poses greater challenges due to overspray and toxic fumes, whereas sherardizing produces less hazardous waste, enhancing overall environmental sustainability.

Cost Considerations and Efficiency

Thermal spraying involves applying a zinc coating through a molten or semi-molten state, offering high adhesion and versatility for large or complex structures but often at a higher initial equipment and operational cost. Sherardizing uses a dry diffusion process by tumbling steel components with zinc powder at elevated temperatures, providing uniform coatings with lower material waste and typically reduced energy consumption, resulting in lower overall process costs. Cost efficiency depends on part size, geometry, production volume, and desired coating thickness, with sherardizing favored for small to medium parts and thermal spraying preferred for extensive or onsite applications.

Thermal Spraying vs Sherardizing Infographic

materialdif.com

materialdif.com