Zinc oxide production involves roasting zinc ore followed by high-temperature reduction, resulting in a white powder widely used in rubber, cosmetics, and pharmaceuticals due to its UV protection and antimicrobial properties. Zinc sulfate production typically uses zinc metal or ore reacted with sulfuric acid, producing a soluble compound commonly used in agriculture as a fertilizer additive and in animal feed for its essential nutritional benefits. The choice between zinc oxide and zinc sulfate production depends on the intended application, with oxide favored for industrial and topical uses and sulfate preferred for dietary supplementation and soil treatment.

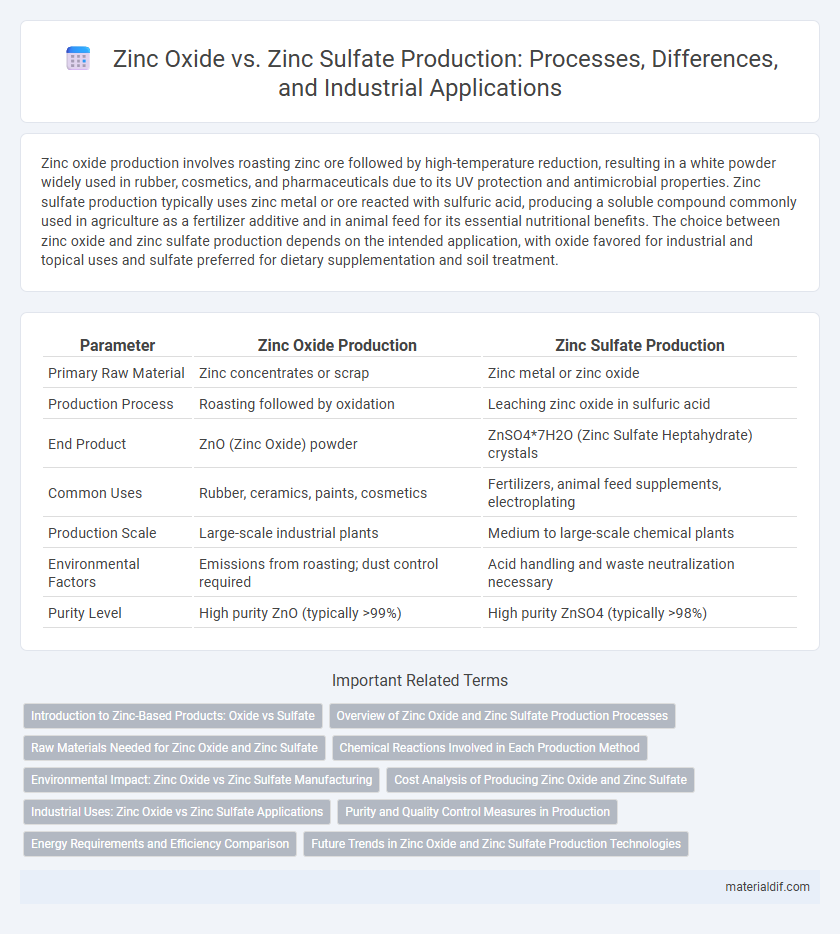

Table of Comparison

| Parameter | Zinc Oxide Production | Zinc Sulfate Production |

|---|---|---|

| Primary Raw Material | Zinc concentrates or scrap | Zinc metal or zinc oxide |

| Production Process | Roasting followed by oxidation | Leaching zinc oxide in sulfuric acid |

| End Product | ZnO (Zinc Oxide) powder | ZnSO4*7H2O (Zinc Sulfate Heptahydrate) crystals |

| Common Uses | Rubber, ceramics, paints, cosmetics | Fertilizers, animal feed supplements, electroplating |

| Production Scale | Large-scale industrial plants | Medium to large-scale chemical plants |

| Environmental Factors | Emissions from roasting; dust control required | Acid handling and waste neutralization necessary |

| Purity Level | High purity ZnO (typically >99%) | High purity ZnSO4 (typically >98%) |

Introduction to Zinc-Based Products: Oxide vs Sulfate

Zinc oxide and zinc sulfate are two primary zinc-based products with distinct industrial applications and production methods. Zinc oxide is produced through indirect or direct oxidation of zinc vapor, widely used in rubber manufacturing, paints, and cosmetics due to its antimicrobial and UV-blocking properties. Zinc sulfate, synthesized by reacting zinc with sulfuric acid, serves crucial roles in agriculture as a micronutrient fertilizer and in animal feed supplementation.

Overview of Zinc Oxide and Zinc Sulfate Production Processes

Zinc oxide production primarily involves the indirect (French) process, where metallic zinc is vaporized and then oxidized in a reactor to form zinc oxide powder, widely used in rubber and cosmetics. Zinc sulfate production typically entails the reaction of zinc metal or zinc oxide with sulfuric acid, producing a clear, water-soluble compound used mainly as a nutritional supplement and in agriculture. Both processes rely on different raw materials and chemical reactions, with zinc oxide emphasizing vapor phase oxidation and zinc sulfate focusing on acid-base reaction for its synthesis.

Raw Materials Needed for Zinc Oxide and Zinc Sulfate

Zinc oxide production primarily relies on high-purity zinc ore or zinc concentrates, often derived from sphalerite, processed through roasting and reduction methods to extract metallic zinc. In contrast, zinc sulfate production requires refined metallic zinc or zinc oxide as raw materials, which are dissolved in sulfuric acid to create the sulfate compound. The source quality and form of zinc significantly influence the efficiency and purity of both zinc oxide and zinc sulfate manufacturing processes.

Chemical Reactions Involved in Each Production Method

Zinc oxide production primarily involves the indirect or direct oxidation of zinc vapor, where zinc metal reacts with oxygen at high temperatures to form ZnO. In contrast, zinc sulfate production entails the reaction of zinc metal or zinc oxide with sulfuric acid, resulting in the formation of ZnSO4 and water. These distinct chemical reactions define the key industrial processes and applications for each zinc compound.

Environmental Impact: Zinc Oxide vs Zinc Sulfate Manufacturing

Zinc oxide production primarily involves oxidation of zinc ore at high temperatures, releasing fewer harmful emissions compared to the sulfate process, which uses sulfuric acid and generates more acidic wastewater. Zinc sulfate manufacturing produces significant effluents containing heavy metals and sulfate ions, posing higher risks of water pollution and soil contamination. Environmental regulations often favor zinc oxide production due to its lower toxicity and reduced chemical waste.

Cost Analysis of Producing Zinc Oxide and Zinc Sulfate

Zinc oxide production typically incurs higher costs due to the energy-intensive roasting and vapor phase oxidation processes required, whereas zinc sulfate production benefits from lower energy expenditure through hydrometallurgical leaching methods. Raw material availability and the scale of production significantly influence overall expenses, with zinc sulfate production often favored in industries prioritizing cost efficiency for fertilizer and animal feed applications. Operational costs, including energy consumption, equipment maintenance, and waste management, further distinguish zinc oxide as the more expensive output compared to zinc sulfate.

Industrial Uses: Zinc Oxide vs Zinc Sulfate Applications

Zinc oxide is primarily used in industrial applications such as rubber manufacturing, ceramics, paints, and pharmaceuticals due to its excellent antimicrobial and UV-absorbing properties. Zinc sulfate is widely employed in agriculture as a micronutrient fertilizer and in animal feed to promote growth and prevent zinc deficiency. The choice between zinc oxide and zinc sulfate production depends on the specific industrial requirements, with zinc oxide favored for material enhancement and zinc sulfate for nutritional supplementation.

Purity and Quality Control Measures in Production

Zinc oxide production emphasizes high purity levels, typically achieving over 99.9% zinc content, through rigorous calcination and vaporization techniques that remove impurities effectively. Zinc sulfate production involves careful crystallization and filtration processes to ensure consistent quality, with purity generally ranging between 98% and 99.5%, depending on the raw material source. Quality control measures for both include real-time compositional analysis using XRF and ICP-MS, alongside stringent monitoring of particle size and solubility to meet industry standards in pharmaceuticals, agriculture, and personal care.

Energy Requirements and Efficiency Comparison

Zinc oxide production typically demands higher energy input due to the roasting process of zinc sulfide ores, while zinc sulfate production involves lower energy usage through hydrometallurgical leaching and purification. Efficiency in zinc sulfate production is enhanced by reduced thermal energy consumption and simpler processing steps, leading to cost-effective scalability. Energy efficiency metrics reveal that zinc sulfate production can lower overall operational energy by approximately 20-30% compared to zinc oxide manufacturing.

Future Trends in Zinc Oxide and Zinc Sulfate Production Technologies

Emerging advancements in zinc oxide production emphasize eco-friendly methods such as vapor-phase oxidation and bioleaching, which reduce energy consumption and carbon emissions. Zinc sulfate production technologies are increasingly integrating electrochemical processes and solvent extraction techniques to enhance purity and yield while minimizing environmental impact. Future trends highlight the shift towards sustainable, cost-efficient production routes driven by stricter environmental regulations and growing demand in agricultural and pharmaceutical applications.

Zinc Oxide Production vs Zinc Sulfate Production Infographic

materialdif.com

materialdif.com