Zinc die casting offers superior strength and dimensional stability compared to aluminum die casting, making it ideal for complex, high-precision pet components. Zinc's excellent wear resistance and corrosion durability extend the lifespan of pet product parts, ensuring reliability in various environmental conditions. Aluminum die casting is lighter and provides better heat dissipation but typically lacks the density and toughness zinc alloys deliver for heavy-duty pet applications.

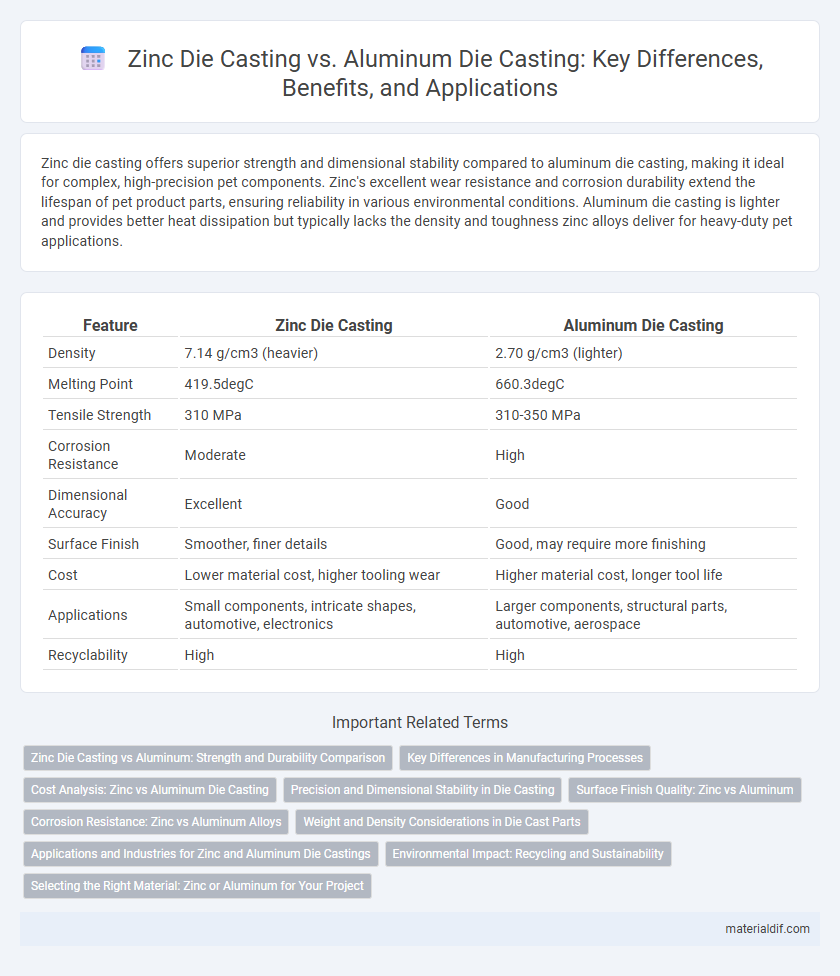

Table of Comparison

| Feature | Zinc Die Casting | Aluminum Die Casting |

|---|---|---|

| Density | 7.14 g/cm3 (heavier) | 2.70 g/cm3 (lighter) |

| Melting Point | 419.5degC | 660.3degC |

| Tensile Strength | 310 MPa | 310-350 MPa |

| Corrosion Resistance | Moderate | High |

| Dimensional Accuracy | Excellent | Good |

| Surface Finish | Smoother, finer details | Good, may require more finishing |

| Cost | Lower material cost, higher tooling wear | Higher material cost, longer tool life |

| Applications | Small components, intricate shapes, automotive, electronics | Larger components, structural parts, automotive, aerospace |

| Recyclability | High | High |

Zinc Die Casting vs Aluminum: Strength and Durability Comparison

Zinc die casting offers superior strength and durability compared to aluminum die casting due to its higher tensile strength, typically around 410 MPa versus aluminum's 310 MPa. Zinc alloys exhibit better impact resistance and wear properties, making them ideal for applications requiring long-lasting structural integrity. Additionally, zinc's lower melting point ensures dimensional stability and less thermal distortion during the casting process, enhancing overall product durability.

Key Differences in Manufacturing Processes

Zinc die casting offers lower melting points around 420degC, enabling faster production cycles compared to aluminum's higher melting point near 660degC, which requires more energy and longer cooling times. Zinc's excellent fluidity allows for more intricate and thin-walled parts, while aluminum provides superior strength-to-weight ratio and better corrosion resistance. The choice between zinc and aluminum die casting hinges on balancing production speed, part complexity, and mechanical properties specific to the application.

Cost Analysis: Zinc vs Aluminum Die Casting

Zinc die casting offers lower tooling costs and faster cycle times compared to aluminum die casting, resulting in reduced overall production expenses, particularly for high-volume runs. Zinc's higher density allows for thinner walls and more intricate designs without sacrificing strength, which can decrease material usage and post-processing costs. While aluminum provides superior corrosion resistance and lighter weight, zinc's cost-effectiveness makes it the preferred choice when budget constraints and rapid manufacturing are critical factors.

Precision and Dimensional Stability in Die Casting

Zinc die casting offers superior precision and dimensional stability compared to aluminum die casting due to its lower melting point and finer fluidity, enabling intricate, complex shapes with tighter tolerances. Zinc alloys exhibit less thermal expansion and better resistance to warping during cooling, resulting in consistently accurate dimensions and reduced post-casting machining. These properties make zinc ideal for manufacturing components that demand high precision and stable dimensions over time.

Surface Finish Quality: Zinc vs Aluminum

Zinc die casting delivers superior surface finish quality compared to aluminum due to its lower melting point and finer grain structure, resulting in smoother, more detailed castings with minimal porosity. Aluminum die cast parts often require additional machining or surface treatments to achieve comparable aesthetics because of their rougher texture and higher susceptibility to oxidation. The enhanced dimensional accuracy and surface smoothness of zinc castings make them ideal for applications where visual appeal and precise detailing are critical.

Corrosion Resistance: Zinc vs Aluminum Alloys

Zinc die casting offers superior corrosion resistance compared to many aluminum alloys due to its natural ability to form a protective oxide layer that prevents further oxidation. Aluminum alloys, while also resistant to corrosion, often require additional coatings or treatments to achieve similar durability in harsh environments. This makes zinc die cast components preferable for applications exposed to moisture and chemical exposure, ensuring longer lifespan and reduced maintenance costs.

Weight and Density Considerations in Die Cast Parts

Zinc die casting parts typically weigh more than aluminum counterparts due to zinc's higher density of approximately 7.14 g/cm3 compared to aluminum's 2.70 g/cm3. This density difference affects the overall weight and strength of die cast components, with zinc offering superior durability in heavier applications. Designers often select aluminum die casting for lightweight requirements, whereas zinc is preferred when additional weight and strength are critical.

Applications and Industries for Zinc and Aluminum Die Castings

Zinc die casting is extensively used in automotive, electrical, and hardware industries due to its excellent dimensional stability, high strength, and corrosion resistance, making it ideal for small intricate parts and components such as brackets, housings, and connectors. Aluminum die casting finds widespread application in aerospace, consumer electronics, and automotive sectors, favored for its lightweight properties, high thermal conductivity, and superior corrosion resistance, enabling production of structural components, engine parts, and heat sinks. Both materials serve critical roles where precision and durability are essential, with zinc preferred for high-volume small-to-medium parts and aluminum selected for larger, weight-sensitive applications.

Environmental Impact: Recycling and Sustainability

Zinc die casting offers superior environmental benefits due to its high recyclability and lower energy consumption during melting compared to aluminum die casting. Zinc's ability to be recycled repeatedly without quality degradation reduces waste and conserves natural resources, supporting sustainable manufacturing practices. In contrast, aluminum die casting requires more energy-intensive processes and often involves greater carbon emissions, impacting overall environmental sustainability.

Selecting the Right Material: Zinc or Aluminum for Your Project

Zinc die casting offers superior dimensional accuracy and higher strength per weight compared to aluminum, making it ideal for complex, high-precision components. Aluminum die casting is preferred for projects requiring lightweight parts with excellent corrosion resistance and thermal conductivity. Selecting the right material depends on specific project needs such as mechanical stress, environmental exposure, and cost constraints.

Zinc Die Casting vs Aluminum Die Casting Infographic

materialdif.com

materialdif.com