ZAMAK and ZA-8 are popular zinc alloys used in manufacturing Zinc PET components due to their strength and corrosion resistance. ZAMAK offers excellent dimensional stability and is ideal for precision parts, while ZA-8 provides higher tensile strength and improved wear resistance, making it suitable for more demanding applications. Choosing between ZAMAK and ZA-8 depends on the specific mechanical requirements and environmental conditions of the Zinc PET product.

Table of Comparison

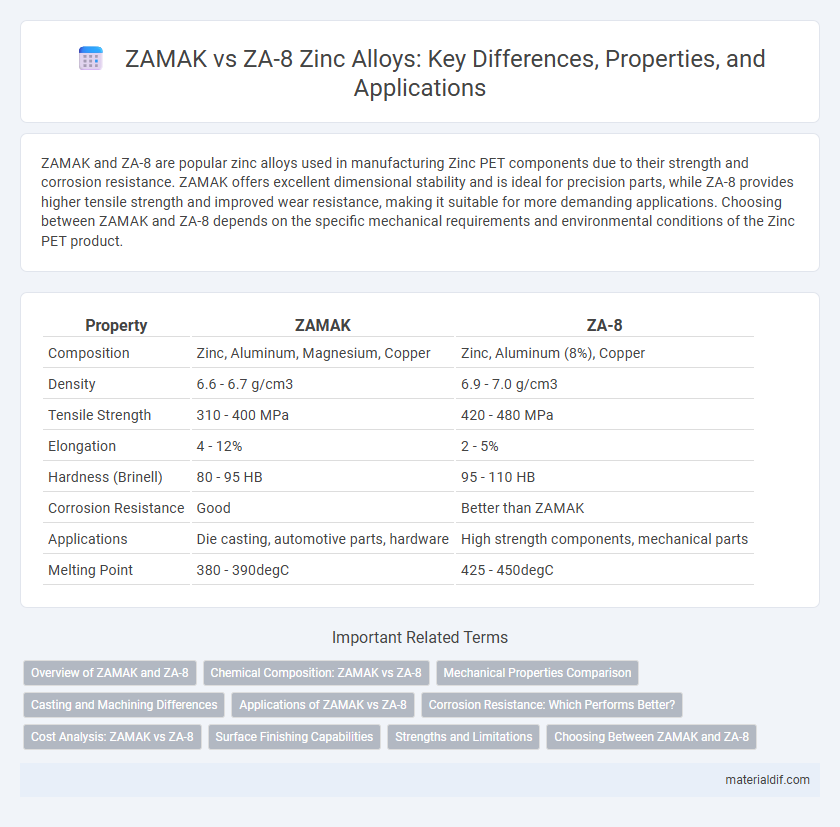

| Property | ZAMAK | ZA-8 |

|---|---|---|

| Composition | Zinc, Aluminum, Magnesium, Copper | Zinc, Aluminum (8%), Copper |

| Density | 6.6 - 6.7 g/cm3 | 6.9 - 7.0 g/cm3 |

| Tensile Strength | 310 - 400 MPa | 420 - 480 MPa |

| Elongation | 4 - 12% | 2 - 5% |

| Hardness (Brinell) | 80 - 95 HB | 95 - 110 HB |

| Corrosion Resistance | Good | Better than ZAMAK |

| Applications | Die casting, automotive parts, hardware | High strength components, mechanical parts |

| Melting Point | 380 - 390degC | 425 - 450degC |

Overview of ZAMAK and ZA-8

ZAMAK is a family of zinc alloys primarily composed of zinc, aluminum, magnesium, and copper, known for high strength, excellent castability, and corrosion resistance in die casting applications. ZA-8, a zinc-aluminum alloy characterized by approximately 8% aluminum content, offers superior wear resistance and mechanical strength compared to standard ZAMAK grades, making it suitable for high-stress components. Both alloys are widely used in automotive, hardware, and electrical industries, with ZAMAK preferred for fine details and ZA-8 favored for durability under heavy loads.

Chemical Composition: ZAMAK vs ZA-8

ZAMAK alloys primarily consist of approximately 95% zinc, combined with 4% aluminum, 1% magnesium, and trace amounts of copper, optimizing strength and corrosion resistance. ZA-8, in contrast, contains about 91% zinc and a higher aluminum content, approximately 8%, which significantly enhances hardness and wear resistance. The increased aluminum percentage in ZA-8 makes it suitable for applications requiring superior mechanical properties compared to the more ductile ZAMAK series.

Mechanical Properties Comparison

ZAMAK alloys, primarily composed of zinc with aluminum, magnesium, and copper, exhibit higher tensile strength and better impact resistance compared to ZA-8, which has a higher aluminum content but lower mechanical robustness. ZA-8 offers good fluidity and castability, suitable for intricate shapes but typically lacks the fatigue strength and ductility found in ZAMAK variants. Mechanical properties such as yield strength and elongation percentage clearly favor ZAMAK alloys in applications demanding durability and structural integrity.

Casting and Machining Differences

ZAMAK alloys, primarily composed of zinc with aluminum, magnesium, and copper, offer excellent die-casting properties, resulting in fine surface finishes and tight dimensional tolerances, ideal for intricate shapes. ZA-8, a zinc-aluminum alloy with higher aluminum content, exhibits superior strength and wear resistance but presents more challenges in machining due to its increased hardness compared to ZAMAK. While ZAMAK's lower melting point enhances castability and reduces tooling wear, ZA-8 requires more robust machining tools and slower speeds to achieve optimal surface quality.

Applications of ZAMAK vs ZA-8

ZAMAK alloys, primarily used in die-casting applications, excel in producing automotive components, household hardware, and electrical connectors due to their superior strength and corrosion resistance. ZA-8, enriched with aluminum, offers enhanced hardness and wear resistance, making it ideal for manufacturing gears, bearings, and heavy-duty mechanical parts requiring durability under stress. Both materials are pivotal in industrial sectors, with ZAMAK favored for intricate shapes and ZA-8 preferred for applications demanding higher mechanical performance.

Corrosion Resistance: Which Performs Better?

ZAMAK alloys typically offer superior corrosion resistance compared to ZA-8 due to their higher purity zinc content and uniform microstructure, which reduces susceptibility to corrosion. ZA-8, containing a higher aluminum percentage, tends to form a less protective oxide layer, making it more prone to environmental degradation in harsh conditions. For applications requiring enhanced durability in corrosive environments, ZAMAK remains the preferred choice.

Cost Analysis: ZAMAK vs ZA-8

ZAMAK alloys typically offer lower material and production costs compared to ZA-8 due to their higher availability and simpler casting processes. ZA-8, containing higher aluminum content, provides superior mechanical properties but at an increased raw material price and processing complexity. Cost analysis reveals ZAMAK as more economical for high-volume manufacturing, while ZA-8 suits applications demanding enhanced strength despite higher expenses.

Surface Finishing Capabilities

ZAMAK alloys exhibit superior surface finishing capabilities compared to ZA-8 due to their finer grain structure, which allows for smoother and more consistent finishes in plating and painting applications. The higher zinc content and specific aluminum-magnesium proportions in ZAMAK contribute to enhanced polishability and corrosion resistance, making it ideal for decorative parts. ZA-8, while offering good castability and mechanical strength, often requires more extensive surface preparation to achieve comparable finish quality.

Strengths and Limitations

ZAMAK alloys, primarily composed of zinc with aluminum, magnesium, and copper, offer excellent corrosion resistance and dimensional stability, making them ideal for precision die casting applications. ZA-8, with a higher aluminum content, provides superior strength and hardness compared to standard ZAMAK but exhibits increased brittleness and reduced ductility, limiting its use in high-impact environments. While ZAMAK balances malleability and strength for versatile use, ZA-8 specializes in applications requiring enhanced mechanical properties at the expense of toughness.

Choosing Between ZAMAK and ZA-8

Choosing between ZAMAK and ZA-8 alloys depends on application requirements such as strength, corrosion resistance, and cost-efficiency. ZAMAK offers excellent dimensional stability and is commonly used in die casting for precision components, while ZA-8 boasts higher strength and hardness, making it suitable for more demanding mechanical parts. Evaluating environmental conditions and mechanical stress will guide the optimal selection between these zinc-based alloys.

ZAMAK vs ZA-8 Infographic

materialdif.com

materialdif.com