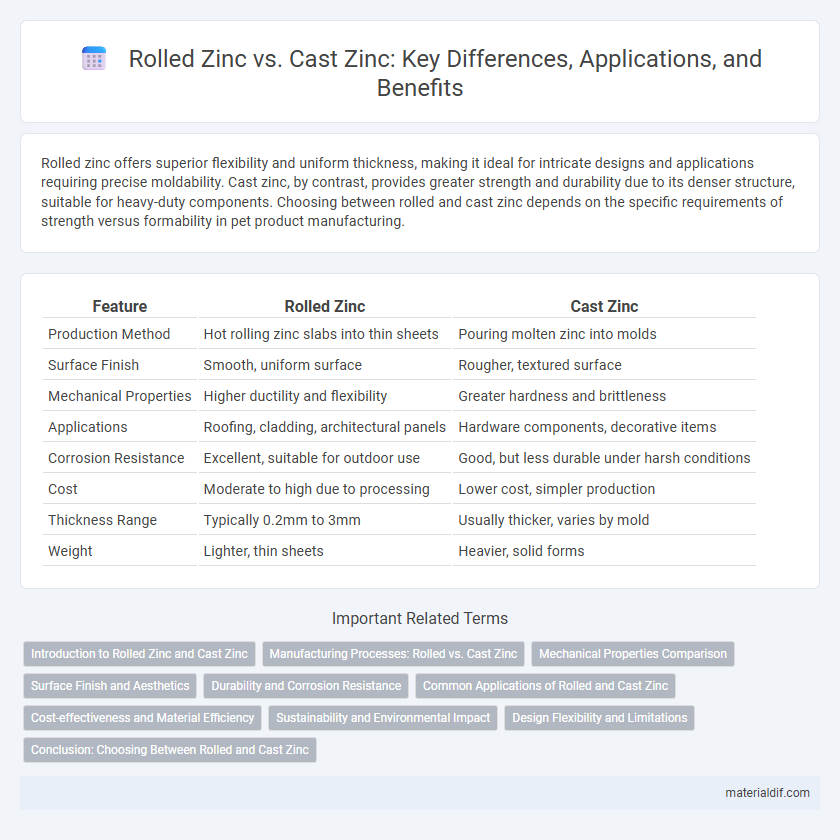

Rolled zinc offers superior flexibility and uniform thickness, making it ideal for intricate designs and applications requiring precise moldability. Cast zinc, by contrast, provides greater strength and durability due to its denser structure, suitable for heavy-duty components. Choosing between rolled and cast zinc depends on the specific requirements of strength versus formability in pet product manufacturing.

Table of Comparison

| Feature | Rolled Zinc | Cast Zinc |

|---|---|---|

| Production Method | Hot rolling zinc slabs into thin sheets | Pouring molten zinc into molds |

| Surface Finish | Smooth, uniform surface | Rougher, textured surface |

| Mechanical Properties | Higher ductility and flexibility | Greater hardness and brittleness |

| Applications | Roofing, cladding, architectural panels | Hardware components, decorative items |

| Corrosion Resistance | Excellent, suitable for outdoor use | Good, but less durable under harsh conditions |

| Cost | Moderate to high due to processing | Lower cost, simpler production |

| Thickness Range | Typically 0.2mm to 3mm | Usually thicker, varies by mold |

| Weight | Lighter, thin sheets | Heavier, solid forms |

Introduction to Rolled Zinc and Cast Zinc

Rolled zinc is produced by passing zinc slabs through rollers to achieve thin, uniform sheets commonly used in architectural cladding and roofing applications due to its flexibility and smooth surface. Cast zinc is created by melting zinc and pouring it into molds, resulting in denser, more rigid components often utilized in decorative elements and corrosion-resistant fittings. Understanding these manufacturing differences is crucial for selecting the appropriate zinc form based on specific construction or industrial needs.

Manufacturing Processes: Rolled vs. Cast Zinc

Rolled zinc is produced by heating zinc ingots and passing them through rollers to create thin, uniform sheets with enhanced mechanical properties and smooth surface finishes. Cast zinc involves melting zinc and pouring it into molds to solidify, resulting in components with varied thickness and more intricate shapes but generally lower tensile strength than rolled zinc. The rolling process improves zinc's ductility and structural consistency, while casting allows for complex design flexibility in manufacturing zinc products.

Mechanical Properties Comparison

Rolled zinc exhibits superior mechanical properties compared to cast zinc, including higher tensile strength and improved ductility, making it more suitable for applications requiring flexibility and durability. The grain structure of rolled zinc is finer and more uniform, enhancing its mechanical performance and resistance to cracking under stress. Cast zinc typically has a coarser grain size, resulting in increased brittleness and lower impact resistance.

Surface Finish and Aesthetics

Rolled zinc offers a smoother surface finish with consistent texture, making it ideal for architectural applications that demand uniform aesthetics. Cast zinc, on the other hand, presents a natural matte finish with subtle variations, adding character but less uniformity. The choice between rolled and cast zinc depends on whether precise surface smoothness or distinctive visual appeal is prioritized.

Durability and Corrosion Resistance

Rolled zinc exhibits superior durability and corrosion resistance due to its dense, uniform microstructure formed through cold working, enhancing its protective oxide layer. Cast zinc tends to have a more porous structure, which can reduce its long-term resistance to environmental factors such as moisture and pollutants. Consequently, rolled zinc is preferred in applications requiring extended lifespan and reliable corrosion protection.

Common Applications of Rolled and Cast Zinc

Rolled zinc is commonly used in roofing, gutters, and architectural cladding due to its malleability and ability to be formed into thin sheets for detailed applications. Cast zinc finds extensive use in die-casting for producing intricate parts in automotive components, hardware fittings, and electrical housings because of its high strength and dimensional stability. Both forms of zinc serve essential roles in construction and manufacturing, with rolled zinc favored for surface applications and cast zinc for durable, precision-engineered parts.

Cost-effectiveness and Material Efficiency

Rolled zinc offers superior material efficiency due to its ability to be produced in uniform, thin sheets, reducing waste and optimizing usage in roofing and cladding applications. Cast zinc, while providing greater design flexibility for intricate shapes, generally incurs higher production costs and material waste, making it less cost-effective for large-scale projects. Choosing rolled zinc typically results in lower overall expenses and enhanced sustainability through efficient resource utilization.

Sustainability and Environmental Impact

Rolled zinc offers superior sustainability due to its efficient manufacturing process that consumes less energy and reduces carbon emissions compared to cast zinc production. Cast zinc involves melting at higher temperatures, leading to increased greenhouse gas emissions and greater resource depletion. The recyclability of rolled zinc also enhances its environmental profile, promoting a circular economy with minimal waste generation.

Design Flexibility and Limitations

Rolled zinc offers superior design flexibility compared to cast zinc due to its ability to be easily shaped, bent, and molded into complex forms without compromising structural integrity. Cast zinc, while providing excellent durability and weight-bearing capacity, is limited by rigid molds, restricting intricate design possibilities and resulting in heavier components. Choosing rolled zinc enables architects and designers to achieve innovative, lightweight solutions, whereas cast zinc suits applications requiring robust, static forms.

Conclusion: Choosing Between Rolled and Cast Zinc

Rolled zinc offers higher tensile strength and better flexibility, making it ideal for roofing, cladding, and architectural applications where durability and precise dimensions are crucial. Cast zinc provides superior corrosion resistance and intricate design capabilities, suited for decorative elements and detailed hardware components. Selecting between rolled and cast zinc depends on project requirements, balancing strength, detail, and environmental exposure for optimal performance.

Rolled Zinc vs Cast Zinc Infographic

materialdif.com

materialdif.com