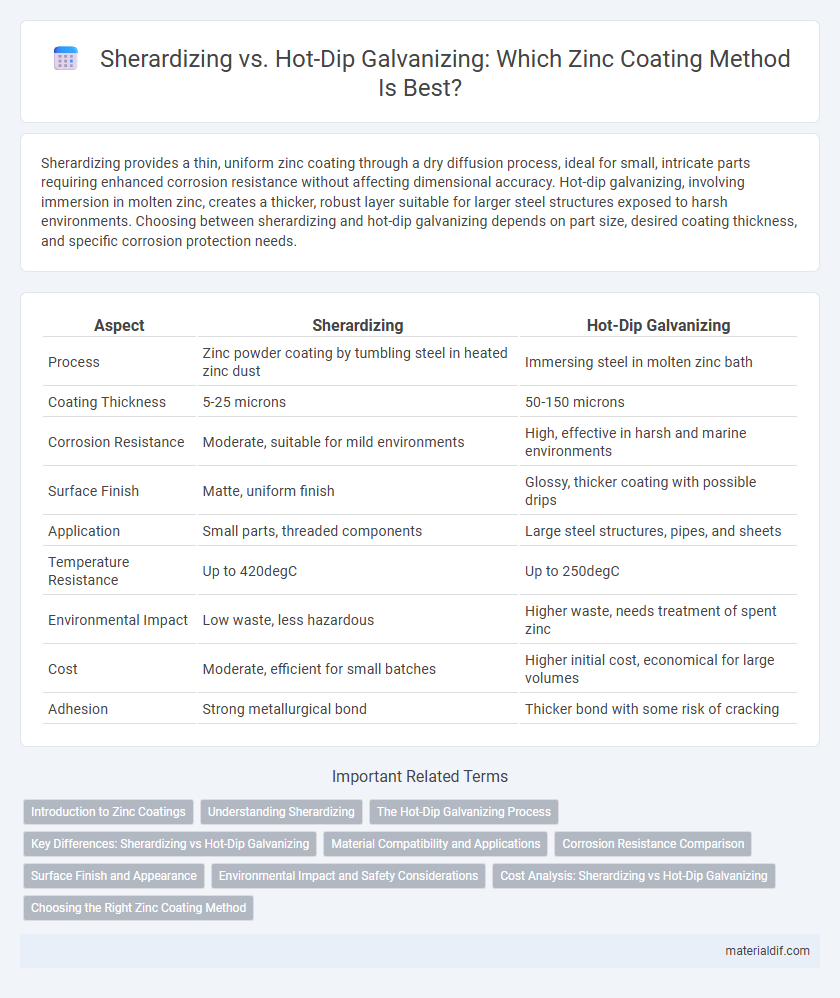

Sherardizing provides a thin, uniform zinc coating through a dry diffusion process, ideal for small, intricate parts requiring enhanced corrosion resistance without affecting dimensional accuracy. Hot-dip galvanizing, involving immersion in molten zinc, creates a thicker, robust layer suitable for larger steel structures exposed to harsh environments. Choosing between sherardizing and hot-dip galvanizing depends on part size, desired coating thickness, and specific corrosion protection needs.

Table of Comparison

| Aspect | Sherardizing | Hot-Dip Galvanizing |

|---|---|---|

| Process | Zinc powder coating by tumbling steel in heated zinc dust | Immersing steel in molten zinc bath |

| Coating Thickness | 5-25 microns | 50-150 microns |

| Corrosion Resistance | Moderate, suitable for mild environments | High, effective in harsh and marine environments |

| Surface Finish | Matte, uniform finish | Glossy, thicker coating with possible drips |

| Application | Small parts, threaded components | Large steel structures, pipes, and sheets |

| Temperature Resistance | Up to 420degC | Up to 250degC |

| Environmental Impact | Low waste, less hazardous | Higher waste, needs treatment of spent zinc |

| Cost | Moderate, efficient for small batches | Higher initial cost, economical for large volumes |

| Adhesion | Strong metallurgical bond | Thicker bond with some risk of cracking |

Introduction to Zinc Coatings

Zinc coatings provide essential corrosion resistance for steel surfaces, with Sherardizing and Hot-Dip Galvanizing as two prominent methods. Sherardizing involves a dry process where zinc powder diffuses onto the substrate at elevated temperatures, resulting in a uniform zinc-iron alloy layer. Hot-Dip Galvanizing immerses steel into molten zinc, creating a metallurgically bonded coating with superior thickness and durability.

Understanding Sherardizing

Sherardizing involves diffusing zinc into the surface of steel components at temperatures typically between 300degC and 400degC, creating a uniform, hard, and corrosion-resistant zinc-iron alloy layer. Compared to hot-dip galvanizing, which coats steel by immersing it in molten zinc, sherardizing offers superior adhesion, minimal dimensional changes, and excellent corrosion protection for small or complex-shaped parts. This thermal diffusion process enhances durability without the risk of zinc runoff or buildup, making sherardizing ideal for fasteners, springs, and precision components requiring consistent coating thickness.

The Hot-Dip Galvanizing Process

The hot-dip galvanizing process involves immersing steel or iron components into a bath of molten zinc, typically heated to around 450degC, creating a robust metallurgical bond between the zinc coating and the base metal. This method produces a thick, corrosion-resistant layer that provides long-lasting protection in harsh environments, making it ideal for structural steel, outdoor equipment, and automotive parts. The zinc coating formed during hot-dip galvanizing enhances durability by offering sacrificial protection, where the zinc corrodes first, preserving the integrity of the underlying metal.

Key Differences: Sherardizing vs Hot-Dip Galvanizing

Sherardizing involves diffusing zinc into the surface of steel components in a rotating drum at temperatures around 300degC, creating a uniform, thin zinc-iron alloy coating with excellent corrosion resistance and minimal dimensional change. Hot-dip galvanizing immerses steel in molten zinc at approximately 450degC, forming a thicker, multi-layered zinc coating that offers robust protection but can alter part dimensions and surface texture. Key differences include temperature, coating thickness, dimensional impact, and suitability for complex geometries, with sherardizing favored for small, intricate parts and hot-dip galvanizing preferred for larger structural steel elements.

Material Compatibility and Applications

Sherardizing offers superior coating uniformity on small, intricate steel parts and ensures excellent adhesion on high-strength alloys without altering mechanical properties, making it ideal for precision components and fasteners. Hot-dip galvanizing provides a robust, heavy zinc layer optimal for structural steel and outdoor applications where thick corrosion protection is essential. Material compatibility dictates Sherardizing for delicate or heat-sensitive materials, while hot-dip galvanizing suits larger, rugged steel assemblies exposed to harsh environments.

Corrosion Resistance Comparison

Sherardizing creates a uniform zinc-iron alloy layer that offers superior corrosion resistance in harsh environments compared to hot-dip galvanizing's thicker, yet more brittle zinc coating. The sherardized layer's metallurgical bond enhances durability and reduces susceptibility to flaking and cracking. Hot-dip galvanizing is effective in moderate conditions but may underperform against prolonged exposure to moisture and corrosive agents relative to sherardizing.

Surface Finish and Appearance

Sherardizing produces a smooth, uniform zinc-iron alloy coating with a matte gray finish that resists chipping and flaking, ideal for intricate parts. Hot-dip galvanizing results in a thicker, rougher coating with a spangled, shiny appearance that provides robust corrosion protection but may show drip marks. The choice between Sherardizing and hot-dip galvanizing depends on the desired combination of surface finish smoothness and visual aesthetics.

Environmental Impact and Safety Considerations

Sherardizing offers a lower environmental impact than hot-dip galvanizing by avoiding the use of hazardous chemicals and reducing zinc runoff, leading to less soil and water contamination. The sealed nature of the sherardizing process minimizes worker exposure to toxic fumes and molten zinc, enhancing workplace safety compared to the open baths used in hot-dip galvanizing. Hot-dip galvanizing involves higher energy consumption and produces more waste, increasing its ecological footprint and potential risks to human health.

Cost Analysis: Sherardizing vs Hot-Dip Galvanizing

Sherardizing offers a cost-effective solution for coating small, complex parts by utilizing a dry diffusion process that reduces labor and material expenses compared to hot-dip galvanizing. Hot-dip galvanizing, involving immersion in molten zinc, incurs higher energy consumption and requires extensive post-treatment, increasing overall costs. For large or structural steel components, hot-dip galvanizing's durability justifies its higher price, while sherrardizing remains economical for precision parts with thinner, uniform coatings.

Choosing the Right Zinc Coating Method

Sherardizing offers superior uniformity and corrosion resistance for intricate parts due to its diffusion process, while hot-dip galvanizing provides thicker, more robust coatings ideal for large steel structures exposed to harsh environments. Selecting the appropriate zinc coating method depends on factors such as part complexity, desired coating thickness, environmental conditions, and cost considerations. For precision components requiring smooth finishes and wear resistance, sherardizing is optimal, whereas heavy-duty applications benefit from the durability and impact resistance of hot-dip galvanizing.

Sherardizing vs Hot-Dip Galvanizing Infographic

materialdif.com

materialdif.com