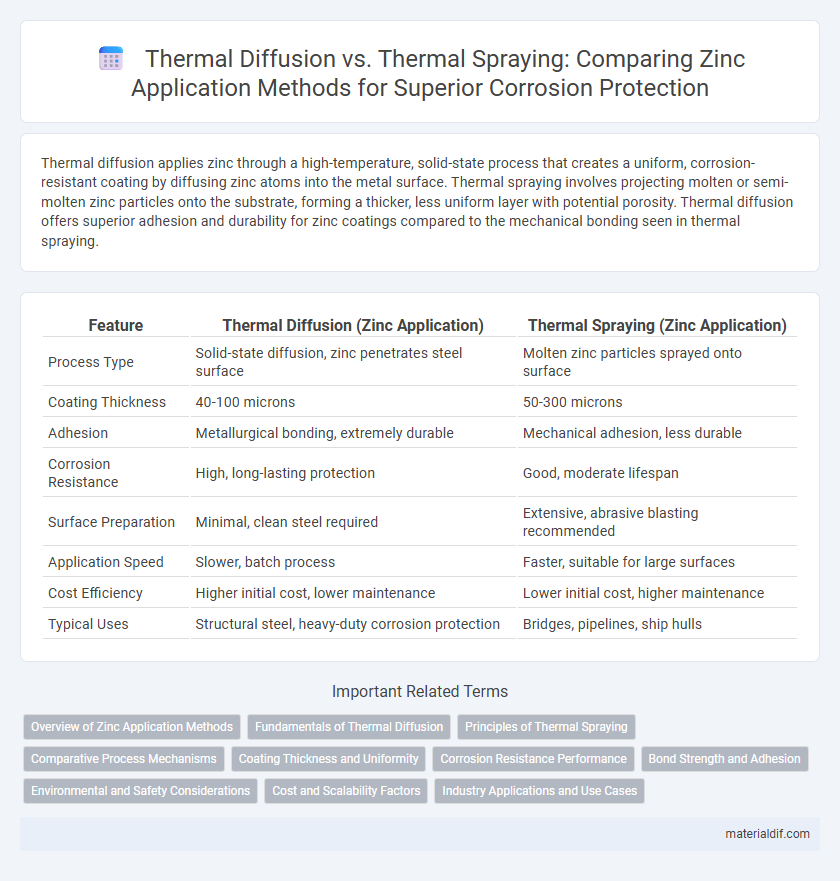

Thermal diffusion applies zinc through a high-temperature, solid-state process that creates a uniform, corrosion-resistant coating by diffusing zinc atoms into the metal surface. Thermal spraying involves projecting molten or semi-molten zinc particles onto the substrate, forming a thicker, less uniform layer with potential porosity. Thermal diffusion offers superior adhesion and durability for zinc coatings compared to the mechanical bonding seen in thermal spraying.

Table of Comparison

| Feature | Thermal Diffusion (Zinc Application) | Thermal Spraying (Zinc Application) |

|---|---|---|

| Process Type | Solid-state diffusion, zinc penetrates steel surface | Molten zinc particles sprayed onto surface |

| Coating Thickness | 40-100 microns | 50-300 microns |

| Adhesion | Metallurgical bonding, extremely durable | Mechanical adhesion, less durable |

| Corrosion Resistance | High, long-lasting protection | Good, moderate lifespan |

| Surface Preparation | Minimal, clean steel required | Extensive, abrasive blasting recommended |

| Application Speed | Slower, batch process | Faster, suitable for large surfaces |

| Cost Efficiency | Higher initial cost, lower maintenance | Lower initial cost, higher maintenance |

| Typical Uses | Structural steel, heavy-duty corrosion protection | Bridges, pipelines, ship hulls |

Overview of Zinc Application Methods

Zinc application methods such as thermal diffusion and thermal spraying offer distinct advantages in corrosion protection. Thermal diffusion involves a heat-driven process creating a diffusion layer that enhances adhesion and durability of zinc coatings on steel surfaces. Thermal spraying applies molten zinc particles to a substrate, producing a thicker, more uniform protective layer ideal for complex geometries and rapid coating requirements.

Fundamentals of Thermal Diffusion

Thermal diffusion in zinc application involves the solid-state diffusion of zinc atoms into the substrate metal at elevated temperatures, creating a metallurgical bond that enhances corrosion resistance and wear properties. This process relies on precise temperature control, typically between 400degC and 550degC, to enable atomic diffusion without melting the substrate. Unlike thermal spraying, which deposits a molten zinc layer, thermal diffusion forms an integral zinc-iron alloy layer, resulting in superior adhesion and longer-lasting protection.

Principles of Thermal Spraying

Thermal spraying applies zinc coatings by propelling molten or semi-molten zinc particles at high velocity onto a substrate, creating a dense, adherent protective layer that enhances corrosion resistance. This process relies on the principle of heat transfer and kinetic energy to form a uniform zinc coating without altering the base material's properties. Compared to thermal diffusion, thermal spraying offers faster application times and versatility in coating thickness and substrate types, making it ideal for large or complex surfaces.

Comparative Process Mechanisms

Thermal diffusion applies zinc through a controlled chemical reaction at elevated temperatures, creating a metallurgical bond with the steel substrate, which enhances corrosion resistance and wear properties. Thermal spraying propels molten or semi-molten zinc particles onto the surface, forming a mechanical coating layer that provides sacrificial protection but with less metallurgical integration. The key difference lies in thermal diffusion's atomic-level zinc diffusion into the base metal versus thermal spraying's physical deposition of zinc coatings.

Coating Thickness and Uniformity

Thermal diffusion zinc coating typically achieves a thinner and more uniform layer, generally around 5-15 microns, ensuring consistent protection on complex geometries. Thermal spraying can apply much thicker coatings ranging from 50 to 200 microns but often results in less uniformity due to overspray and surface irregularities. The choice between the two methods depends on the required coating thickness and the importance of uniform corrosion resistance for specific industrial applications.

Corrosion Resistance Performance

Thermal diffusion zinc coating forms a metallurgical bond with the substrate, offering superior corrosion resistance through uniform zinc penetration and enhanced durability in harsh environments. Thermal spraying applies molten zinc onto surfaces, creating a thicker but more porous layer prone to mechanical damage and less consistent protection. Studies reveal thermal diffusion coatings outperform thermal sprayed layers in salt spray tests, extending service life in marine and industrial atmospheres.

Bond Strength and Adhesion

Thermal diffusion of zinc involves a high-temperature process that creates a metallurgical bond with the substrate, resulting in superior bond strength and enhanced adhesion compared to thermal spraying. In contrast, thermal spraying deposits zinc particles mechanically onto the surface, producing a coating with weaker adhesion prone to delamination under stress. Therefore, thermal diffusion is preferred for applications requiring long-lasting, durable zinc coatings with excellent corrosion protection.

Environmental and Safety Considerations

Thermal diffusion zinc coating involves lower energy consumption and emits fewer volatile organic compounds compared to thermal spraying, reducing environmental impact. Thermal spraying releases zinc particles and fumes that require specialized ventilation and personal protective equipment to mitigate respiratory hazards for workers. Selecting thermal diffusion can enhance workplace safety and lower ecological footprint by minimizing airborne contaminants and waste generation.

Cost and Scalability Factors

Thermal diffusion zinc application typically involves higher initial costs due to specialized equipment but offers scalable, uniform coatings ideal for large, complex steel components in industrial settings. Thermal spraying zinc is more cost-effective for smaller projects or repairs, allowing rapid application on-site with less infrastructure but may require more frequent maintenance due to coating thickness variability. Cost efficiency and scalability depend on project size, desired coating durability, and application environment, with thermal diffusion favored for mass production and thermal spraying suited for flexible, localized treatments.

Industry Applications and Use Cases

Thermal diffusion zinc coating offers superior corrosion resistance and uniform layer thickness, making it ideal for critical applications in automotive and aerospace industries where long-term durability is essential. Thermal spraying zinc is commonly used in heavy infrastructure, such as bridges and industrial plants, due to its ability to apply thick, protective coatings rapidly on large, complex surfaces. Both methods enhance steel protection, but thermal diffusion is preferred for precision components, while thermal spraying suits large-scale, on-site corrosion protection projects.

Thermal diffusion vs Thermal spraying (zinc application) Infographic

materialdif.com

materialdif.com