Powder coating provides a durable, environmentally friendly finish that resists corrosion and wear better than zinc chromate priming. Zinc chromate priming offers excellent adhesion and corrosion resistance but involves toxic chemicals and requires additional topcoats for enhanced protection. Choosing powder coating improves longevity and sustainability in protective coatings for metal surfaces.

Table of Comparison

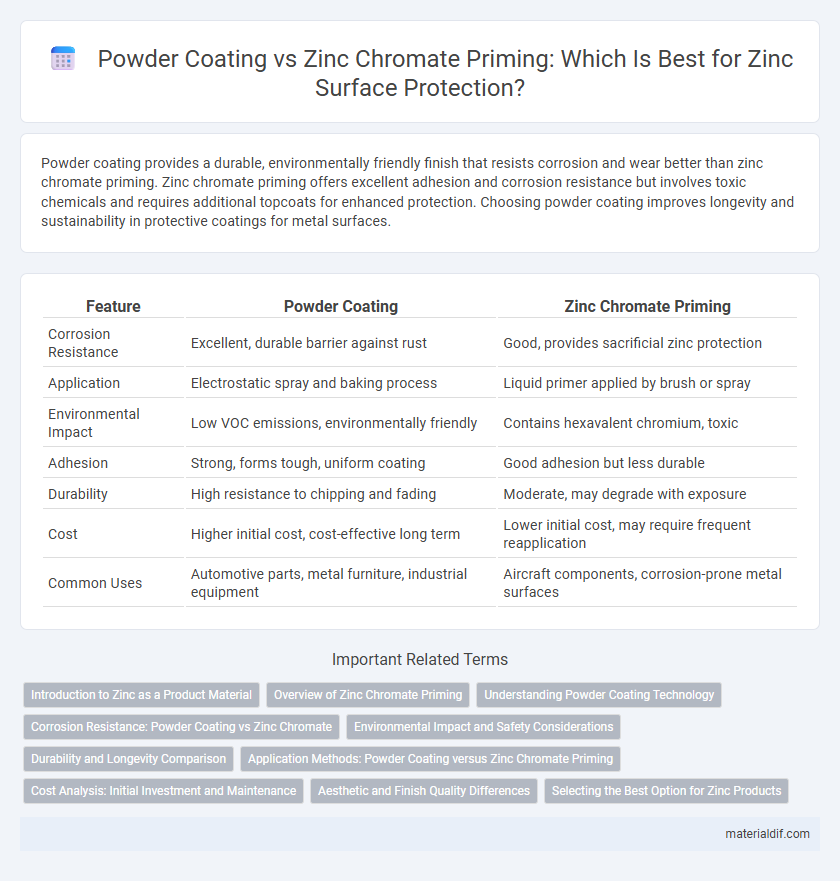

| Feature | Powder Coating | Zinc Chromate Priming |

|---|---|---|

| Corrosion Resistance | Excellent, durable barrier against rust | Good, provides sacrificial zinc protection |

| Application | Electrostatic spray and baking process | Liquid primer applied by brush or spray |

| Environmental Impact | Low VOC emissions, environmentally friendly | Contains hexavalent chromium, toxic |

| Adhesion | Strong, forms tough, uniform coating | Good adhesion but less durable |

| Durability | High resistance to chipping and fading | Moderate, may degrade with exposure |

| Cost | Higher initial cost, cost-effective long term | Lower initial cost, may require frequent reapplication |

| Common Uses | Automotive parts, metal furniture, industrial equipment | Aircraft components, corrosion-prone metal surfaces |

Introduction to Zinc as a Product Material

Zinc is a versatile metal widely used for corrosion protection in industrial applications, with powder coating and zinc chromate priming being common surface treatments. Powder coating offers a durable, environmentally friendly barrier with superior resistance to chipping and weathering, while zinc chromate priming provides excellent adhesion and corrosion inhibition through its chemical composition. Selecting between these coatings depends on specific requirements for durability, environmental impact, and surface protection in diverse manufacturing and construction processes.

Overview of Zinc Chromate Priming

Zinc chromate priming is a corrosion-resistant coating commonly used on metal surfaces to provide a protective base layer before applying paint or powder coating. This primer contains zinc chromate pigments that offer excellent adhesion, durability, and long-lasting protection against rust and oxidation. Compared to powder coating alone, zinc chromate priming enhances surface preparation, improves paint adherence, and significantly extends the lifespan of the coated metal.

Understanding Powder Coating Technology

Powder coating technology enhances corrosion resistance and durability by applying a dry, electrostatically charged powder that cures into a tough, uniform finish, offering superior environmental safety compared to traditional zinc chromate priming. Unlike zinc chromate priming, which relies on toxic chemical compounds for corrosion protection, powder coating eliminates volatile organic compounds (VOCs), making it an eco-friendly alternative with excellent adhesion and impact resistance. This advanced coating method provides longer-lasting protection for metal surfaces, reducing maintenance costs and improving overall performance in industrial and automotive applications.

Corrosion Resistance: Powder Coating vs Zinc Chromate

Powder coating provides a durable, thick, and uniform protective layer that resists corrosion by creating a physical barrier against moisture and chemicals. Zinc chromate priming offers sacrificial protection through the zinc content, which corrodes preferentially to the steel substrate, but may degrade faster under harsh environmental conditions. For long-term corrosion resistance, powder coating generally outperforms zinc chromate by maintaining integrity without significant breakdown or peeling over time.

Environmental Impact and Safety Considerations

Powder coating offers a more environmentally friendly alternative to zinc chromate priming by producing fewer volatile organic compounds (VOCs) and generating less hazardous waste. Zinc chromate primers contain hexavalent chromium, a toxic substance linked to serious health risks including respiratory issues and carcinogenic effects, necessitating strict handling protocols. In comparison, powder coating enhances workplace safety by eliminating exposure to carcinogenic chemicals and reduces environmental pollution through its solvent-free application process.

Durability and Longevity Comparison

Powder coating offers superior durability compared to zinc chromate priming due to its thicker, more uniform protective layer that resists chipping, scratching, and corrosion effectively. Zinc chromate priming provides excellent initial adhesion and corrosion resistance, but its longevity is often compromised by exposure to harsh environmental conditions, leading to potential degradation over time. For applications demanding extended service life and robust environmental protection, powder coating is generally the preferred choice.

Application Methods: Powder Coating versus Zinc Chromate Priming

Powder coating involves electrostatically applying dry powder to a metal surface, which is then cured under heat to form a durable, corrosion-resistant layer, making it ideal for consistent, thick coatings on complex shapes. Zinc chromate priming requires brushing or spraying a liquid primer onto the substrate, offering strong adhesion and corrosion protection through chemical bonding with the metal surface. Powder coating provides a more environmentally friendly and uniform finish, while zinc chromate priming excels in preparing surfaces for subsequent paint layers in aerospace and industrial applications.

Cost Analysis: Initial Investment and Maintenance

Powder coating generally requires a higher initial investment due to specialized equipment and preparation processes, while zinc chromate priming involves lower upfront costs associated with simpler application methods. Maintenance expenses for powder coating tend to be lower because of its durability, corrosion resistance, and color retention, reducing the frequency of reapplications compared to zinc chromate primed surfaces. Over time, the total cost of ownership favors powder coating despite initial expenses, as zinc chromate priming often demands more frequent upkeep and recoating to maintain protective efficacy.

Aesthetic and Finish Quality Differences

Powder coating offers a smoother, more uniform finish with a wide range of vibrant color options, enhancing aesthetic appeal for both industrial and decorative applications. Zinc chromate priming provides a matte, thinner coat primarily focused on corrosion resistance rather than visual quality, often requiring additional topcoats for a polished appearance. The finish durability of powder coating generally surpasses zinc chromate priming, maintaining color integrity and gloss over time under harsh environmental conditions.

Selecting the Best Option for Zinc Products

Powder coating provides a durable, corrosion-resistant finish ideal for zinc products exposed to harsh environments, forming a thick, uniform protective barrier. Zinc chromate priming offers strong adhesion and excellent corrosion protection for metal substrates but involves hazardous chemicals and requires additional topcoats for optimal performance. Choosing between powder coating and zinc chromate priming depends on factors like environmental exposure, desired longevity, and safety considerations in zinc product applications.

Powder coating vs Zinc chromate priming Infographic

materialdif.com

materialdif.com